Description

This clear, water-based polyurethane floor finish is formulated with a low-VOC formula to maintain indoor air quality while simultaneously delivering superior protection. Furthermore, the water-based urethane coating offers exceptional scratch resistance and durability; as a result, it stands as the best water-based floor finish for demanding environments such as warehouses, parking lots, sports courts, and medical facilities.

Detailed Introduction

WPU100 water-based polyurethane floor finish is a two-component, self-drying, reactive curing coating. Formulated with water-based resin emulsion, premium pigments, and functional additives, this high-performance decorative topcoat provides superior durability, wear resistance, and chemical protection. Consequently, it is an ideal choice for concrete floors, indoor parking lots, industrial plants, and sports facilities.

Thanks to its easy application and fast drying time, this water-based polyurethane for concrete floors offers a cost-effective, long-lasting protective solution. Therefore, whether you need a water-based urethane finish for new installations or maintenance, WPU100 stands out as the best water-based polyurethane floor finish available.

Leveraging advanced waterborne polyurethane floor finish technology, it ensures a durable water-based polyurethane top coat that maintains its protective qualities even under heavy use. For this reason, professionals seeking the best water-based poly for floors will find that WPU100 delivers superior performance as a water-based urethane concrete sealer, ultimately outperforming traditional options.

Main Features

- High-performance finish: Provides a matte water-based polyurethane for floors with soft gloss and high hardness.

- Superior scratch resistance: Ensures long-lasting protection for industrial floors, concrete surfaces, and wooden floors.

- Cost-effective application: Requires less usage per unit area, offering best water based polyurethane for floors at a competitive price.

- Environmentally friendly: A low-VOC waterborne polyurethane floor finish that ensures indoor air quality.

Application Scope

- Industrial plants & warehouses

- Surface ramps & parking lots

- Sports courts (basketball courts, gym floors, etc.)

- Medical facilities (hospitals, clinics, etc.)

- Cafeterias & commercial kitchens

Product Information

- Two-component system:

- Component A: Colored viscous liquid (4kg per barrel)

- Component B: Transparent curing agent (0.8kg per barrel)

- Packaging: High-quality printed metal packaging drum, recommended stacking limit: three layers.

- Storage conditions: Keep in a cool, dry, ventilated warehouse (temperature: 5-35°C). Avoid direct sunlight and heat sources.

Technical Data

- Appearance: Smooth and even after stirring, no lumps or impurities.

- Adhesion: Level 1 (strong bonding).

- Hardness: >4H, ensuring superior surface protection.

- Wear resistance: <0.04, offering excellent durability.

- Drying time:

- Surface dry: Within 4 hours

- Fully cured: Within 24 hours (at 25°C, relative humidity 50%)

Substrate Requirements

- Concrete compressive strength: ≥20Mpa

- Tensile strength: ≥1.5Mpa

- Flatness requirement: ±4mm/2m (based on ruler measurement).

- The surface must be dry, clean, and free from oil stains or debris.

Construction Tips

- Mixing time: Components A and B must be mixed and used within 60 minutes. If viscosity increases significantly, discard the mixture.

- Environment: Ensure a clean, dust-free workspace for the best coating effect.

- Airflow impact: Adequate ventilation speeds up drying.

- Temperature restrictions: Do not apply when the temperature is below 5°C.

Construction Conditions

- Substrate temperature: 5-35℃

- Environmental temperature: 5-35℃

- Moisture content of ground base: <8%

- Relative humidity: <80%

Construction Methods & Tools

- No dilution required

- Application method: Scrape evenly, then use a roller to smooth out.

- Recommended tools: Roller brush

Safety Precautions

- Personal protection: Wear gloves, masks, and protective clothing.

- Ventilation: Maintain airflow in the working environment.

- First-aid measures:

- Skin contact: Rinse with plenty of water.

- Eye contact: Flush with water and seek medical help if necessary.

- Inhalation: Move to fresh air, seek medical assistance if feeling unwell.

- Ingestion: Rinse mouth, induce vomiting, seek medical attention.

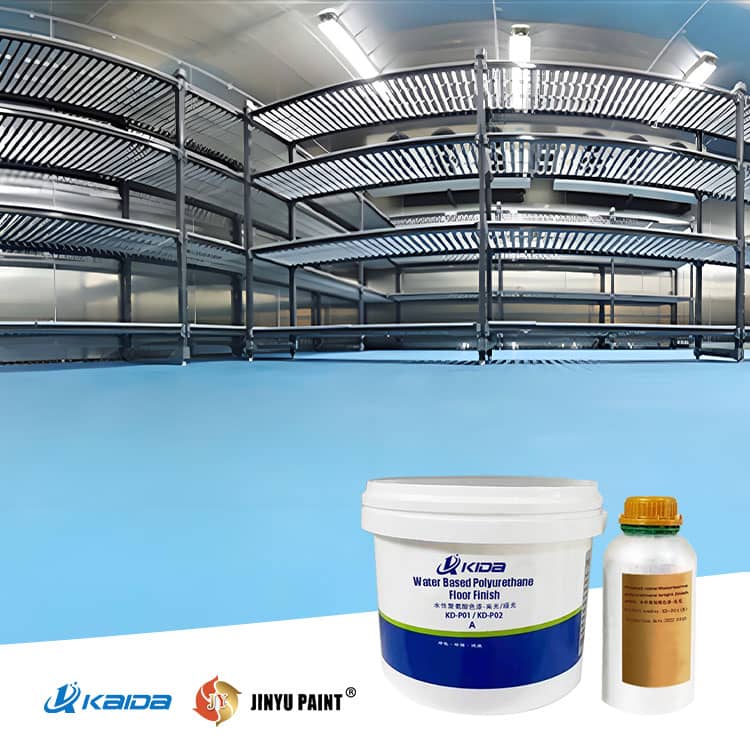

Sleek, gloss finish waterborne polyurethane floor in an electronics assembly plant, enhancing brightness and providing a dust-free surface.

High-performance waterborne polyurethane flooring in a high-traffic warehouse, showing excellent resistance to abrasion from pallet movement.