Ultra Wear-resistant Polyurethane Flooring System

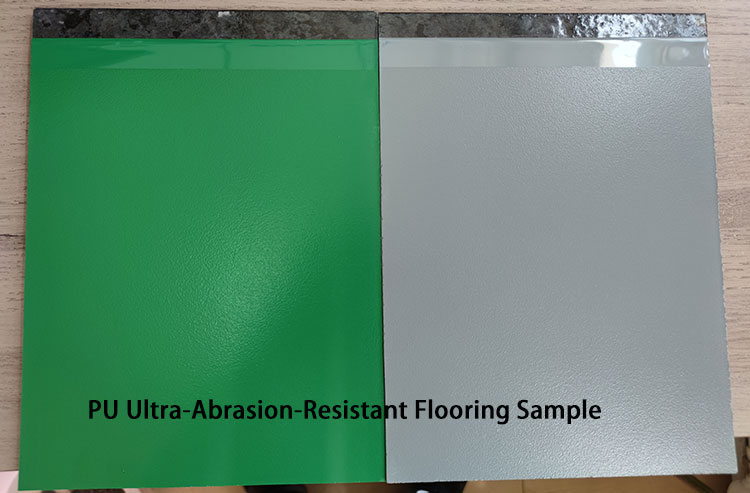

High-Performance Polyurethane Ultra Abrasion-Resistant Flooring

Superior durability, scratch resistance, and chemical protection for industrial & commercial spaces.

Our polyurethane ultra-wear-resistant flooring combines high-strength polyurethane resins with rounded, ultra-hard wear-resistant aggregates to deliver:

- 3x higher abrasion resistance than standard epoxy floors.

- Outstanding weather resistance—ideal for outdoor applications (e.g., stadiums,colored bleachers).

- Reduced tire noise thanks to a fine-textured, anti-slip surface.

- Exceptional resistance to stains, oils, acids, alkalis, and tire marks.

Key Advantages:

- Unmatched mechanical strength & adhesion for long-lasting performance.

- Seamless, dustproof, and easy to clean—perfect for pharmaceutical factories, food plants, and laboratories.

- UV-resistant (no yellowing or fading outdoors).

- Custom formulations: Solvent-based, waterborne polyurethane, 100% solids, or powder coatings.

Polyurethane Ultra-Wear-Resistant Floor Coating

1. Unmatched Physical Performance

- Nano-enhanced polyurethane composite delivers 3x higher abrasion resistance vs. standard epoxy floors.

- Heavy-duty industrial flooring withstands high-frequency friction from forklifts, machinery, and logistics equipment.

2. Smart Eco-Friendly Technology

- Ultra-low VOC emissions (1/3 of national standards) for healthier indoor air quality.

- Self-regulating molecular sieve structure balances humidity & temperature automatically.

3. Noise-Reduction Innovation

- Micro-textured surface design reduces tire/vehicle noise by 8–12 dB—ideal for quiet industrial floors.

4. Self-Cleaning Protection

- S8-level impermeability + “lotus-effect” nanotechnology repels oil, stains, and tire marks effortlessly.

Ultra Abrasion-Resistant Flooring Applications:

1. Precision Laboratories

Anti-static polyurethane flooring with ESD-safe formulas to protect sensitive instruments.

2. Smart Warehousing

Integrated smart guidance line systems for automated logistics efficiency.

3. Child-Friendly Spaces

Food-grade certified flooring + anti-slip & antimicrobial treatment for safety.

4. Commercial Complexes

Customizable 3D decorative flooring with anti-wear properties for high-end aesthetics.

5. Pharmaceutical Cleanrooms

GMP-certified seamless flooring for ultra-hygienic environments.

6. Outdoor Facilities

UV-resistant polyurethane coating maintains color for 10+ years.

7. Cold Chain Storage

-40°C resistant flooring for freezer warehouses and logistics hubs.

8. Smart Parking Garages

Durable flooring with integrated navigation markings for automated systems.

Industrial flooring

Warehouses, manufacturing plants, workshops.

Commercial spaces

Shopping malls, offices, classrooms, kindergartens.

High-traffic areas

Parking garages, public corridors, airports.

Specialized environments

Chemical-resistant flooring for labs, FDA-compliant flooring for food processing.

Application Products

-

PU3600 Polyurethane Ultra Abrasion Resistant Finish

Read more -

Anti-slip Self-leveling Anticorrosive Load-bearing Polyurethane Concrete Floor Paint

Read more -

Self-leveling Heavy-duty Anticorrosive Polyurethane Concrete Floor Coating

Read more -

WPU100 High Gloss Clear Water-based Polyurethane Finishs

Read more -

WPU100 Water-based Polyurethane Floor Finish

Read more

Polyurethane Ultra-Wear-Resistant Flooring System: Technical Construction Specification

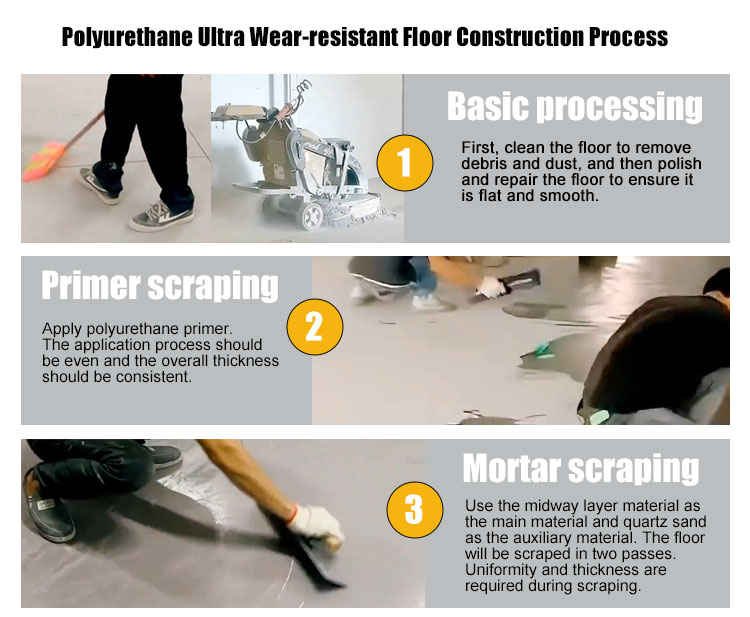

1.1 Substrate Preparation

(1) Flatness: ≤2–3mm height differential under a 2m straightedge (per GB 50209-2010 standards).

(2) Concrete Base:

- Minimum 50mm thick commercial fine-aggregate concrete leveling layer with waterproofing (negative-side waterproofing membrane).

- Compressive strength ≥C25; no dusting, delamination, or efflorescence.(3) Defect Remediation: Eliminate voids, cracks, oil stains, or laitance via mechanical grinding (ASCC 302R-04 compliance).(4) Curing: New slabs require 28-day moist curing; no dry-shake hardeners during troweling.(5) Moisture Content: ≤8% (ASTM F1869) – verify via CM testing.

1.2 Material & Equipment Storage

- Flammables Storage: ISO 3679-compliant zone; minimum 10m from ignition sources.

- Machinery: Dedicated area with lockout/tagout protocols.

2.1 Site Isolation

- Erect barriers; protect wall/column edges with PVC bumpers.

2.2 Mechanical Surface Preparation

- Diamond Grinding (30–40 grit): Remove laitance, expose pores (SSPC-SP 13/NACE No. 6).

- Crack Repair: Inject epoxy-quartz slurry (1:3 mix ratio) into fissures >0.2mm.

- Vacuuming: Achieve ≤St2 cleanliness (ISO 8501-1).

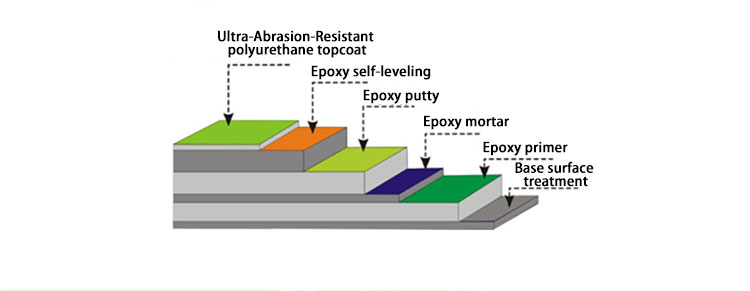

2.3 Epoxy Primer Application

- Mix Ratio: 4:1 (resin:hardener) – stir 3min at 500rpm (per ASTM C881).

- Application: Roller/notched squeegee; target 0.15–0.2kg/m² coverage.

- Cure: 8h @ 25°C; RH <75%.Key Benefit: Enhances adhesion (≥3.5MPa pull-off, ASTM D4541) and seals pores.

2.4 Epoxy Mortar Intermediate Coat

- Mix Design: 3:1 resin:hardener + 40–70 mesh quartz sand (60% by weight).

- Troweling: 2mm thickness; eliminate bubbles with spiked rollers.

- Grinding: Post-cure (24h), diamond-grind to ≤0.5mm unevenness.

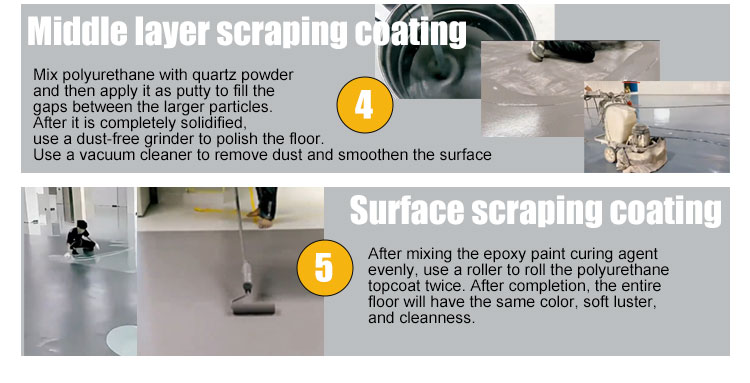

2.5 Epoxy Putty Leveling

- Filler: Talc-filled epoxy (70% solids) – spread at 0.8kg/m².

- Defect Tolerance: ≤1mm/2m after curing (EN 13813).

2.6 Epoxy Self-Leveling Topper

- Flowability: ≥130mm slump (ASTM C1436).

- Application: Dentated squeegee → deaeration with 1.2mm needle roller.

2.7 Polyurethane Ultra-Wear-Resistant Topcoat

- Material: Aliphatic polyurethane (ISO 11341 UV-stable).

- Mixing: 2:1 base:crosslinker – pot life 45min @ 23°C.

- Application:

- 1st coat: Microfiber roller (0.3mm wet film).

- 2nd coat: Cross-directional (0.2mm).

- Cure: Walkable in 8h; full cure @ 168h (Shore D ≥80, ASTM D2240).

- Weather: Ambient 10–35°C; dew point +3°C above substrate temp.

- Contamination: Isolate acid/alkali spills (pH 6–8 tolerance).

- Ventilation: 5 ACH during application (OSHA 1910.107).

- Initial Cure: 24h no traffic; 72h light-duty only.

- Heavy Loads: Permitted after 7d (tested via ASTM D6279).

- Cleaning: Neutral pH cleaners (e.g., Tennant 844).

- Damage Repair: Spot-grind + polyurethane recoating (100% solids recommended).

REQUEST A CALLBACK

For bespoke industry flooring solutions talk to KAIDA® JINYU PAINT® today.

We offer free no obligation advice and can provide a price range on the first contact.

- +86-158-229-255-23(whatsapp)

- kaida@jinyupaint.com

Contact Us

Contact: Ms. Sabella Wei

Phone: 86-022-83859963

Whatsapp: 15822925523

© 2023 JINYU. All Rights Reserved -

Design by JINYU Paint