Flooring For Seafood Processing Plants

A quiet revolution is underway in the newly constructed seafood processing plant, focusing on upgrading the critical flooring system. As the foundational element supporting efficient operations in fisheries facilities, the selection of flooring materials and design profoundly impacts production efficiency, workplace safety, and compliance with stringent hygiene standards. Explore how JINYU PAINT waterborne polyurethane mortar flooring redefines industry benchmarks for seafood plant flooring, offering superior slip resistance, chemical resistance, and USDA/FDA-compliant sanitation—key priorities for fisheries factory flooring solutions. This innovation addresses top concerns like easy-clean seafood processing floors and durable flooring for wet environments, making it the optimal choice for modern seafood and fish processing facilities

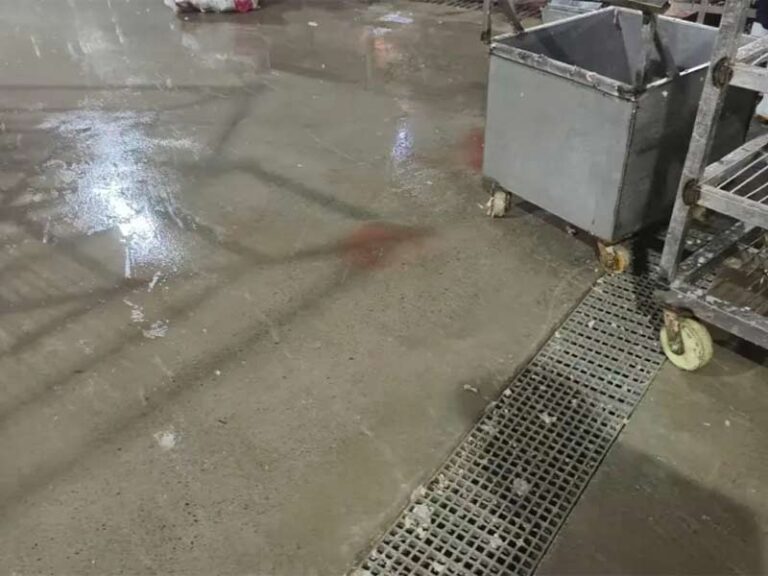

In-Depth Analysis of Traditional Flooring Pain Points in Seafood Processing Plants

Pre-Construction Documentation

Waterproofing failures pose a major challenge, as fisheries factory flooring is constantly exposed to water during daily operations. Traditional floors allow water penetration, degrading cement hydration products over time. This leads to delamination and hollowing—as witnessed in a legacy seafood plant renovation, where water damage caused severe surface deterioration within three years, resulting in costly repairs and production disruptions.

Corrosion vulnerability becomes apparent with acidic/alkaline substances from seafood processing, including fish-derived organic acids and alkaline sanitizers. Standard seafood processing flooring materials deteriorate under chemical exposure, creating pitted surfaces that harbor bacteria and compromise food safety compliance—a critical concern given rising global searches for FDA-approved seafood plant floors.

Slip hazards escalate in perpetually wet environments. Conventional fisheries flooring suffers dramatic friction reduction when wet, directly contributing to worker slips—a leading cause of injuries in seafood facilities. Industry data confirms slip-related accidents account for a significant percentage of workplace incidents, impacting both employee welfare and operational continuity.

Poor abrasion resistance fails to withstand relentless mechanical stress from cargo handling, forklift traffic, and equipment movement. Generic seafood factory floors develop sanding and premature wear, triggering unplanned maintenance. This directly increases operational costs and downtime—key pain points reflected in high-search terms like heavy-duty flooring for seafood plants and low-maintenance fisheries flooring solutions.

Advantages of Water based Polyurethane Mortar Flooring for Seafood Processing Plants

Superior Waterproof Performance

JINYU PAINT® water based polyurethane mortar flooring utilizes a specialized polyurethane formulation that creates a dense molecular structure, acting like a waterproof shield for seafood plant flooring. This advanced technology prevents water penetration, effectively eliminating common issues such as delamination and hollowing caused by water exposure. Even under prolonged washing and soaking in fisheries factory environments, the flooring remains intact and durable.

Exceptional Chemical Resistance

Engineered to withstand harsh conditions, this seafood processing flooring demonstrates outstanding resistance to acids, alkalis, and other corrosive substances commonly found in seafood production. Its unique chemical composition preserves surface integrity and smoothness, minimizing bacterial growth and ensuring compliance with stringent food safety standards—a critical requirement for modern FDA-approved seafood facilities.

Advanced Slip-Resistant Properties

Featuring specialized texture technology, JINYU PAINT® flooring maintains high friction coefficients even when wet—a game-changer for anti-slip seafood plant flooring. Workers can move confidently on water-covered surfaces, significantly reducing slip-and-fall incidents and enhancing workplace safety in high-moisture fisheries environments.

Unmatched Wear Resistance

Reinforced with high-strength aggregates, this heavy-duty seafood factory flooring withstands relentless mechanical stress from cargo handling, forklift traffic, and equipment movement. The surface retains its smoothness over years of use, slashing maintenance costs and production downtime—key benefits highlighted by industrial searches for long-lasting fisheries flooring solutions.

Post-Installation Results:

The transformed seafood plant flooring showcases a seamless, hygienic surface that meets sanitation protocols while addressing the industry”s top operational challenges—from chemical spills to thermal shock resistance.

JINYU PAINT®: Revolutionizing Flooring Solutions for the Seafood Industry

In the seafood processing industry, the selection of flooring materials directly impacts production efficiency, workplace safety, and hygiene standards—factors that demand meticulous attention. For the newly constructed fisheries factory in Jingzhou, choosing JINYU PAINT® waterborne polyurethane mortar flooring proves to be a visionary decision that ensures long-term operational excellence.

Traditional seafood plant flooring solutions struggle to meet the unique demands of this industry. Poor waterproofing leads to peeling and hollowing when exposed to water; weak corrosion resistance results in surface damage from acids and alkalis, creating breeding grounds for bacteria; inadequate slip resistance increases fall risks on wet surfaces; and insufficient durability causes rapid wear from heavy equipment and frequent material handling—all contributing to rising maintenance costs and operational disruptions.

In stark contrast, JINYU PAINT® polyurethane mortar flooring delivers unmatched performance. Its waterproof seafood flooring technology forms an impermeable barrier, even under prolonged moisture exposure. The chemical-resistant fisheries flooring withstands harsh cleaning agents while maintaining a smooth, easy-to-clean surface. Engineered with anti-slip seafood flooring texture, it ensures worker safety in wet conditions. Most importantly, its heavy-duty seafood plant flooring composition resists abrasion from years of mechanical stress, maintaining structural integrity.

With a single installation, JINYU PAINT® provides a 25-year warranty—eliminating recurring repair expenses and allowing businesses to focus resources on core operations. This long-lasting fisheries flooring solution has become the benchmark for modern seafood facilities, as evidenced by its adoption in leading processing plants worldwide.

For seafood manufacturers evaluating FDA-compliant flooring options, JINYU PAINT® offers a proven solution that combines food-grade safety standards with industrial durability. Discover how our high-performance seafood flooring system can transform your facility’s productivity and safety—just as it has for numerous industry pioneers.

Related Products

-

PU3600 Polyurethane Ultra Abrasion Resistant Finish

Read more -

Anti-slip Self-leveling Anticorrosive Load-bearing Polyurethane Concrete Floor Paint

Read more -

Self-leveling Heavy-duty Anticorrosive Polyurethane Concrete Floor Coating

Read more -

WPU100 High Gloss Clear Water-based Polyurethane Finishs

Read more -

WPU100 Water-based Polyurethane Floor Finish

Read more

REQUEST A CALLBACK

For bespoke industry flooring solutions talk to KAIDA® JINYU PAINT® today.

We offer free no obligation advice and can provide a price range on the first contact.

- +86-158-229-255-23(whatsapp)

- kaida@jinyupaint.com

FAQ

- How to Prevent Thermal Shock Damage in Food-Processing Floors: The Urethane Concrete Solution

- 7 Expert Strategies to Extend the Lifespan of Polyurethane Flooring in High-Traffic Areas

- How to Fix Peeling or Delaminating Polyurethane Flooring: A Definitive Repair Guide

- What are the best practices for installing polyurethane flooring in a pharmaceutical cleanroom?

- What flooring type works best for logistics warehouses with forklift traffic?

Contact Us

Contact: Ms. Sabella Wei

Phone: 86-022-83859963

Whatsapp: 15822925523