JINYU PAINT® Fire Retardant Paint

Fire retardant paint, also known as flame-retardant coating or fire-resistant paint, is a specialized coating applied to combustible substrates (e.g., steel, wood, reinforced concrete). It modifies the material’s burning behavior, reduces flammability, and slows fire spread, thereby improving fire resistance. Beyond fire protection, it offers rust-proofing, waterproofing, corrosion resistance, wear resistance, and heat resistance. In a fire, it forms an insulating layer, shielding the substrate from heat and buying critical time for evacuation and firefighting, minimizing damage.

Fire retardant paint is a vital safety material across industries, enhancing fire resistance and saving lives. With advancing technology and stricter regulations, its market potential continues to grow.

Fire Resistance Test: Can This Coating Stop a Raging Fire?

JINYU PAINT® Fire Retardant Paint

Showing all 10 results

-

KD-NRP-FP-BTCB-1 Indoor Intumescent Steel Structure Fire Resistant Paint

Read more -

KD-NSF-FP-JY-SG Indoor Non-intumescent Steel Structure Fire Proof Paint

Read more -

KD-NSF-FP-STI-A Indoor Non-intumescent Fire Retardant Paint for Steel Structure

Read more -

KD-NSP-FP-SB-3 Indoor Intumescent Fire Resistant Paint for Steel Structure

Read more -

KD-NSP-FP1.50-BTCB-2 Indoor Intumescent Steel Structure Fire Retardant Coating

Read more -

KD-NSP-FP2.00-SB-2 Indoor Intumescent Steel Structure Fire Retardant Coating

Read more -

KD-SMT-S-858 Decorative Fire Retardant Paint for Wood

Read more -

KD-WRP-FP-WCB Outdoor Intumescent Steel Structure Fire Resistant Paint

Read more -

KD-WSF-FT-STI-C Outdoor Non-intumescent Steel Structure Fire Retardant Coating

Read more -

KD-WSP-FT JY-WB Outdoor Intumescent Fire Resistant Paint for Steel Structure

Read more

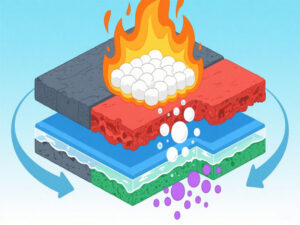

Composition of Fire Retardant Paint

Fire retardant paint typically consists of:

- Binder: Silicate cement, magnesium oxychloride, or inorganic high-temperature adhesives form the coating’s base.

- Pigment: Provides color and opacity while enhancing aesthetics.

- Additives: Modifiers, hardeners, and waterproofing agents improve performance.

- Fire Retardants: Flame inhibitors, intumescent agents, etc., boost fire resistance.

- Dispersing Medium: Water or solvents adjust viscosity for application.

Advantages of Fire Retardant Paint

- Cost-Effective: More affordable than alternative fireproofing methods.

- Easy Application: Adaptable to various substrates.

- Aesthetic Flexibility: Available in decorative finishes.

- Eco-Friendly Options: Low-VOC and water-based variants.

Classification of Fire Retardant Paint

- By Fire Protection Mechanism:

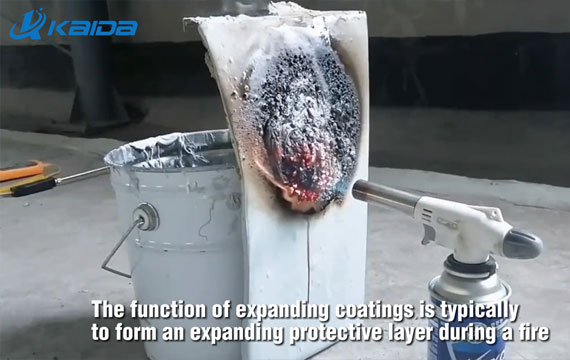

- Non-Intumescent Fire Retardant Paint: Forms a glassy layer when exposed to fire, blocking oxygen and heat transfer.

- Intumescent Fire Retardant Paint: Expands into a foam-like insulating layer under heat, delaying flame spread and releasing non-flammable gases.

- By Application:

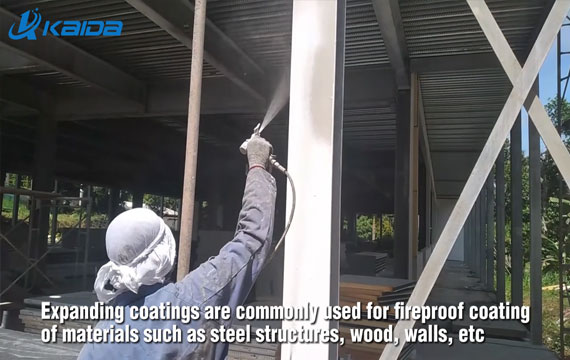

- Structural Steel Fireproof Paint: Protects building steel with thick, low-density, thermally insulating coatings.

- Decorative Fire-Resistant Paint: Combines aesthetics and fire protection for wood, fiberboard, ceilings, and doors.

- Cable Fire Retardant Coating: Shields wires/cables by expanding into a protective char layer.

- By Dispersion Medium:

- Water-Based Fireproof Paint: Eco-friendly, water-soluble formulations.

- Solvent-Based Fireproof Paint: Offers better adhesion but may contain volatile organic compounds (VOCs).

- By Thickness:

- Thick-Film Fireproof Paint: For high fire-resistance durations.

- Thin-Film & Ultra-Thin Fireproof Paint: Relies on chemical expansion for protection with minimal thickness.

Applications of Fire Retardant Paint

- Construction: Fireproofing steel, wood, and concrete structures.

- Transportation: Fire protection for ships, aircraft, and vehicles.

- Electrical: Insulating cables and wiring systems.

- Industrial Facilities: Safeguarding chemical plants, power stations, etc.

Fire Protection Mechanisms

- Inherent Non-Flammability: Delays ignition and combustion.

- Low Thermal Conductivity: Slows heat transfer.

- Release of Inert Gases: Dilutes flammable gases.

- Nitrogen-Based Radical Interruption: Disrupts combustion chain reactions.

- Intumescent Expansion: Creates an insulating foam barrier.

FAQS About Fire Retardant Paint

1. Does fire retardant paint work?

Yes, fire retardant paint is scientifically proven to slow down flame spread and reduce material flammability. When exposed to fire, it forms a protective layer (either through intumescent expansion or a non-combustible barrier) that delays heat transfer, giving occupants more time to evacuate and firefighters more time to respond. Its effectiveness depends on proper application and adherence to safety standards.

2. How long does fire retardant paint last?

The lifespan varies based on the type, environmental conditions, and maintenance. Generally, high-quality fire retardant paint can last 5–15 years indoors. Exterior applications may degrade faster due to UV exposure, moisture, and temperature fluctuations. Regular inspections and recoating (if needed) help maintain its effectiveness.

3. Is there a fire retardant paint?

Yes, fire retardant paint is widely available for different materials (wood, steel, drywall, etc.). Common types include intumescent coatings (expand under heat) and cementitious fireproof paints (create a heat-resistant layer). Brands like Sherwin-Williams, PPG, and Nullifire offer certified options.

4. Can you paint over fire retardant paint?

Yes, but with caution. Use compatible topcoats (e.g., water-based over water-based) to avoid chemical reactions. Avoid thick layers that could hinder the fire-retardant properties. For critical structures, consult the manufacturer’s guidelines or a fire safety expert.

5. How to apply fire retardant paint?

Clean the surface thoroughly, remove grease/rust, and ensure dryness. Apply with a brush, roller, or sprayer in even coats (typically 2–3 layers). Follow the product’s recommended drying time between coats. Thicker coatings (e.g., for steel) may require professional spraying.

6. Is fire retardant paint toxic?

Most modern fire retardant paints are low in toxicity once cured. However, solvent-based variants may release VOCs during application, requiring ventilation. Water-based options are safer for indoor use. Always check MSDS sheets for health and safety data.

7. Is latex paint fire retardant?

Standard latex paint is not fire retardant. However, some latex-based paints are formulated with additives to provide limited flame resistance. For certified fire protection, use paints labeled as “fire-retardant” or “intumescent.”

8. What is fire retardant paint made of?

Key components include binders (e.g., epoxy, silicate), flame inhibitors (e.g., ammonium phosphate), and fillers (e.g., vermiculite). Intumescent paints also contain chemicals that swell into a foam-like char when heated.

9. Where can I buy fire retardant paint?

It’s sold at specialty safety suppliers, hardware stores (e.g., Home Depot, Lowe’s), and online platforms (Amazon, UL-proven brands’ websites). For industrial-grade products, contact manufacturers like 3M or BASF.

10. Does fire retardant damage car paint?

Most fire retardants (e.g., aerial forest-fire sprays) can harm automotive paint due to corrosive chemicals. However, automotive-grade fireproof coatings exist for racing or military vehicles. Regular cars should avoid accidental exposure.

11. How much does fire retardant paint cost?

Prices range from $20–$150 per gallon, depending on type and quality. Intumescent coatings for steel are pricier than wood treatments. Bulk purchases or commercial projects may reduce costs.

12. Can I make DIY fire retardant paint?

While some suggest adding borax or alumina trihydrate to regular paint, DIY mixes lack reliability for life safety. Certified fire retardant paints undergo rigorous testing—professional products are strongly recommended.

13. Is fire retardant paint worth it?

Absolutely for high-risk areas (e.g., commercial buildings, escape routes). It’s a cost-effective way to meet fire codes, lower insurance premiums, and protect lives. For decorative use, balance aesthetics with safety ratings.

14. How to test fire retardant paint?

Professional testing involves ASTM E84 or UL 723 standards (measuring flame spread/smoke development). For simple checks, apply a small sample to a substrate and expose it to a controlled flame (lab testing is more accurate).

15. Why isn’t all paint fire retardant?

Standard paints prioritize color, adhesion, and cost over fire resistance. Fire retardant additives increase production expenses and may alter texture/durability. Regulations mandate fireproofing only in specific applications (e.g., public buildings).

Beijing Airport Fire Resistant Project

How advanced fireproofing solutions ensure ultimate safety at Beijing Airport, combining innovative materials and strict compliance with international aviation fire protection standards.

How Featured JINYU Paints Are Made?

The Industrial Applications of Featured JINYU PAINT®

JINYU PAINT® provides a comprehensive range of high-performance coatings, including epoxy floor coatings, industrial coatings, fireproof coatings, and architectural coatings for interior and exterior walls. Our solutions are designed for durability, aesthetics, and protection across various applications, from residential and commercial buildings to industrial facilities and fire safety projects. Whether you need seamless flooring, corrosion resistance, fire protection, or decorative wall finishes, JINYU PAINT® offers expert coatings to enhance and protect every surface.

LATEST FAQS at JINYU PAINT®

FAQ

- Soybean Processing Flooring Solutions: Why Urethane Mortar is the Industry Standard

- Building a Fortress for Pet Food Safety: Why Specialized Pet Food Plant Flooring is Essential

- Pharmaceutical Flooring Guide: Why Urethane Mortar is the Top Choice for GMP Facilities

- The Ultimate Guide to Food Processing Flooring: Revolutionizing Pre-made Food Production with Urethane Mortar Systems

- The Ultimate Seafood Processing Flooring Solution丨KAIDA JINYU® Delivers High-Performance Floors

Contact Us

Contact: Ms. Sabella Wei

Phone: 86-022-83859963

Whatsapp: 15822925523