Description

Product Overview

The ResuShield™ Mechanical Room SB is a robust, five-coat epoxy flooring system specifically engineered for industrial mechanical rooms and commercial utility spaces. This system integrates a flexible waterproofing membrane with a single broadcast of high-strength silica sand to create a seamless, highly durable, and crack-resistant surface. It provides outstanding resistance to chemicals, abrasion, and physical impact while maintaining a moderate slip-resistant texture. The ResuShield™ Mechanical Room SB epoxy flooring system delivers reliable, long-term protection for critical infrastructure where moisture, chemical spills, and heavy traffic are constant concerns.

User Pain Points & Application Scenarios

Facility managers and contractors face persistent challenges with standard concrete or basic paint solutions in demanding environments. Common industrial flooring failures include:

Cracking and Water Ingress: Substrate movement and thermal stress lead to cracks, allowing water to damage the base and equipment below.

Chemical Degradation: Spills from oils, lubricants, cleaning solutions, and process chemicals quickly break down surfaces, causing pitting and staining.

Rapid Wear and Dusting: Constant foot and equipment traffic wears down the finish, generating hazardous and uncleanable dust (chipping).

Safety Hazards: Slick surfaces, especially when wet or oily, create slip risks for personnel, leading to potential accidents.

Difficult Maintenance: Porous or uneven surfaces trap dirt and grime, making cleaning labor-intensive and ineffective.

The ResuShield™ SB system directly tackles these issues in key application areas such as:

HVAC and Plant Mechanical Rooms: Demanding waterproofing and chemical resistance.

Industrial and Manufacturing Facilities: Exposed to heavy loads, metal shavings, and thermal cycling.

Commercial Building Utility Areas: Including basements, pump rooms, and service corridors.

Light Industrial Warehouses: Requiring a tough, seamless surface for easy cleaning and equipment movement.

Product Solution & Detailed Features

The ResuShield™ Mechanical Room SB epoxy flooring system is a total solution built for performance and longevity.

Core System Advantages:

Superior Crack Bridging: The flexible membrane core allows the flooring to move with the substrate, preventing reflective cracking.

Enhanced Durability: A five-coat build with a broadcast of 20-40 mesh silica sand provides excellent thickness and mechanical wear resistance, far exceeding standard epoxy coatings.

Proven Chemical Resistance: The system’s topcoat is formulated to withstand a broad range of industrial chemicals, oils, and solvents, facilitating easy clean-up and spill containment.

Slip-Resistant Safety: The broadcast aggregate creates a consistent, moderate texture that provides reliable traction, reducing slip hazards even in wet conditions.

Seamless & Hygienic: The fluid-applied, joint-free finish prevents dirt and moisture accumulation, supporting high standards of cleanliness.

Aesthetic Flexibility: Available in standard and custom colors (like gray, white, and beige) with a durable, satin gloss urethane topcoat that resists yellowing.

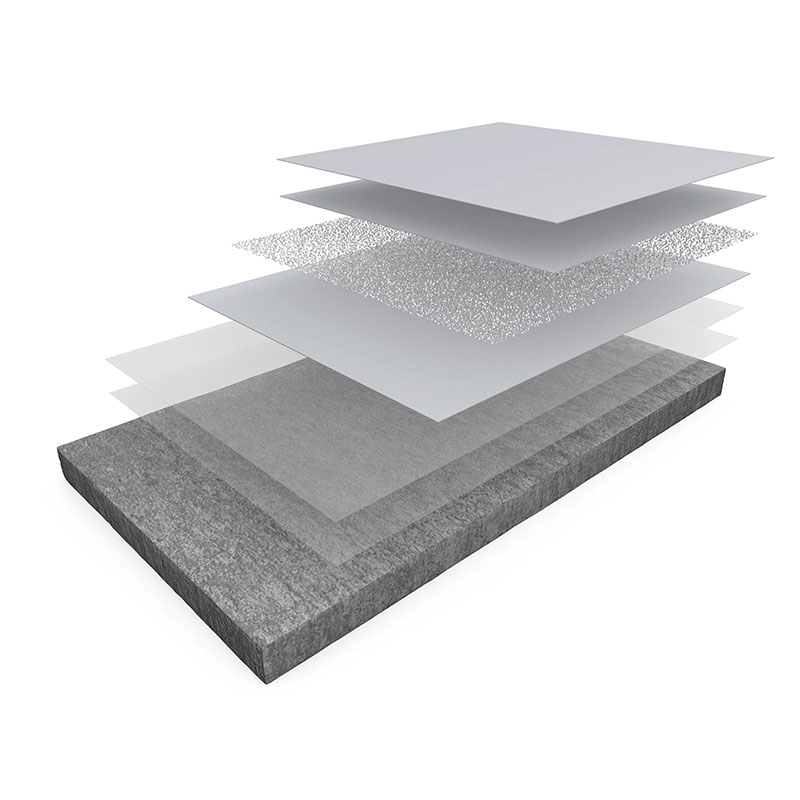

Detailed System Composition:

Primer (ResuShield™ MPE): A flexible epoxy primer ensures strong adhesion to the prepared concrete substrate.

Membrane Build Coats (ResuShield™ 2444): Two 20-mil coats form the primary waterproofing and flexible barrier.

Broadcast Reinforcement: A layer of 20-40 mesh silica sand is broadcast into the wet membrane, embedding for added strength and texture.

Grout Coat (ResuShield™ MPE): Seals the broadcast aggregate, creating a smooth, solid base.

Topcoat (Resutile™ HTS 100): A light-stable urethane topcoat provides the final wear and chemical resistance layer with an attractive satin finish.

Technical Specifications & Authoritative Data

Performance is validated through independent laboratory testing against recognized ASTM standards.

| Property | Test Method | Result | Note |

|---|---|---|---|

| Abrasion Resistance | ASTM D 4060 (CS-17 Wheel, 1000 cycles) | 18 mg loss | Indicates high durability |

| Hardness (Shore D) | ASTM D 2240 | 40 @ 0 sec. | 35 @ 15 sec. |

| Tensile Strength | ASTM D 2370 (7 mils, 3-day cure) | 18,530 psi | Exceptional strength |

| Elongation | ASTM D 2370 (7 mils, 3-day cure) | 125% | High flexibility |

| Adhesion to Concrete | ACI 503R | >300 psi | Cohesive concrete failure |

| Flammability | ASTM D635 | 182 mm/min | |

| VOC Content | — | <50-100 g/L | Low-VOC formulation |

| Service Temperature | — | Up to 140°F (60°C) continuous |

Application Areas

This versatile system is specified by engineers and companies across numerous sectors:

Industrial & Manufacturing: Factory floors, processing areas, warehouse aisles.

Commercial & Institutional: School and hospital mechanical rooms, commercial basements, utility rooms.

Facilities Management: For long-term repair and upgrade projects in existing buildings.

Light Chemical Processing: Areas requiring resistance to occasional chemical spills.

Professional Installation Process & Support

Proper installation by certified contractors is paramount. The key steps include:

Surface Preparation (Prep): Concrete must be abrasive-blasted to a CSP 3-5 profile. All contaminants must be removed, and cracks filled.

Primer Application: The primer is mixed and applied to seal the substrate.

Membrane & Broadcast: The build coats are applied, and silica sand is broadcast for reinforcement.

Grout & Topcoat Application: The grout coat seals the sand, followed by the final urethane topcoat.

Curing: Allow 24 hours for light traffic; full properties develop in 7-14 days.

Our Technical Support: We provide end-to-end support, including specification guidance, application instructions, and on-site assistance for your contractor.

Frequently Asked Questions (FAQ)

What is the main difference between the ResuShield™ SB and DB systems?

The SB is a five-coat system with a single sand broadcast, offering excellent all-around performance. The DB is a six-coat system with a double sand broadcast, designed for even more extreme wear and slip resistance. The SB provides a best value for many industrial mechanical rooms.

What is the approximate cost per square foot?

The cost varies based on substrate condition, project size (square footage), and location. As a premium system, it represents an investment in long-term asset protection. Contact us for a project-specific quote.

Can this be used in a residential garage?

While technically possible, it is over-engineered and not cost-effective for home use. We offer other epoxy and polyurethane kits better suited for diy or residential garage flooring.

How do I clean and maintain this floor?

For routine cleaning, use a bristle brush or power scrubber with a mild detergent. For oil stains, a cleaner/degreaser is effective. The seamless surface makes cleaning much easier than tile grout or bare concrete.

What is the installation timeline?

The multi-coat process typically requires several days, factoring in coating and curing times between layers. The area can usually handle light traffic after 24 hours.

Proof & Trust Building

Performance Backed by Data: Specifications are based on independent ASTM testing, not just claims.

Trusted by Professionals: Used by contractors and companies worldwide for critical infrastructure.

Manufacturer Support: Formulated and supported by industry-leading technical expertise. View project pictures in our gallery.

KAIDA PAINT Brand Introduction

KAIDA PAINT is a leading innovator and supplier of high-performance industrial and commercial coating solutions. We specialize in providing durable products and technical support for facility managers, specifiers, and professional contractors to tackle complex flooring challenges. Our ResuShield™ product line, including the Mechanical Room SB system, embodies our commitment to delivering products that excel under extreme conditions. Backed by rigorous R&D and a global network of experts, we offer more than just coatings; we provide long-term asset protection and peace of mind.

Looking for the optimal flooring solution for your project? Consult with a KAIDA PAINT expert today to get a customized plan and quote.

Partner with KAIDA PAINT

Selecting the right flooring system is a crucial business decision. KAIDA PAINT is a premier manufacturer and supply partner for high-performance industrial coatings. We collaborate with contractors, specifiers, and facility managers to deliver solutions that last.

Our team offers more than products; we provide the expertise to prepare, specify, and apply the optimal system for your unique challenges, whether it’s shielding a mechanical room or upgrading a warehouse. Contact our experts today for a consultation, technical data sheets, or to connect with a certified installer near your city.