Description

As a urethane gloss clear coat, WPU100 provides exceptional protection with a clear high gloss polyurethane appearance. The high gloss urethane clear coat formulation offers fast drying time and easy application, making this best high gloss polyurethane solution both cost-effective and long-lasting for concrete and wooden floors. Whether you need a high gloss polyurethane clear coat for new installations or a high gloss polyurethane over paint for refinishing projects, WPU100 delivers professional results.

For applications requiring maximum shine, this high gloss pu finish outperforms traditional high gloss water based polyurethane options while being more environmentally friendly. The urethane top coat high gloss properties ensure your floors maintain their high gloss poly appearance even under heavy use. As a high gloss pu paint alternative, it combines the durability of industrial coatings with the aesthetic appeal of premium finishes.

Product Introduction

WPU100 water-based polyurethane floor finish is a two-component, self-drying, reactive curing coating. Made from high-quality water-based resins, pigments, and functional additives, it provides high durability, superior adhesion, and resistance to scratches and wear.

This product is designed for sports venues, industrial floors, indoor parking lots, and storage warehouses, meeting the need for aesthetic appeal, durability, and easy maintenance.

Main Features

- Soft gloss & high hardness for long-lasting protection

- Smooth surface & scratch-resistant performance

- Low cost per unit area, maximizing value

- Eco-friendly & low-VOC for a safer indoor environment

Application Scope

- Industrial plants, ramps, parking lots, sports courts, hospitals, and cafeterias

Product Information

- Component A: Solid color viscous liquid (4kg/barrel)

- Component B: Colorless transparent liquid (0.8kg/barrel)

- Packaging: Durable metal container (stackable up to 3 layers)

- Storage: 5-35℃, stored in a cool, ventilated, and dry warehouse, away from heat sources

Technical Data

- Adhesion: Level 1

- Hardness: >4H

- Wear resistance: <0.04

- Drying time: Surface dry < 4 hours, Full cure < 24 hours

Surface Requirements

- Concrete compressive strength ≥ 20Mpa

- Tensile strength ≥ 1.5Mpa

- Surface must be clean, dry, and free from oil and debris

Construction Tips

- Use mixed material within 60 minutes

- Maintain a dust-free environment to ensure smooth application

- Avoid temperatures below 5°C during application

Construction Methods & Tools

- No dilution required

- Application: Scraping + rolling for a smooth finish

- Recommended tools: Roller brush

Usage Instructions

- Surface preparation: Remove dust, gravel, grease, and old coatings

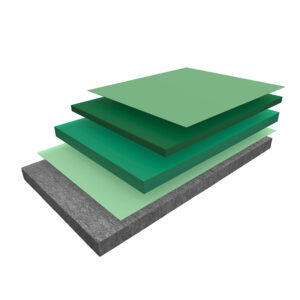

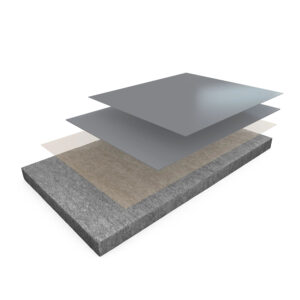

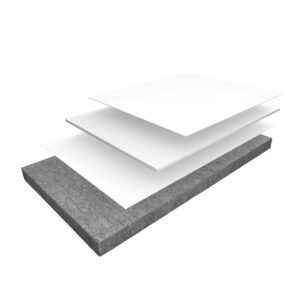

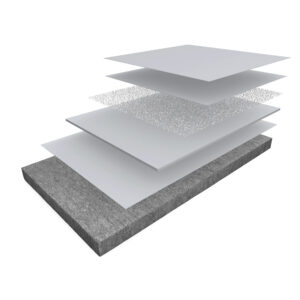

- Apply primer and intermediate coat before the topcoat

- Mixing ratio: Main agent: curing agent = 5:1

Precautions

- Request MSDS for safety details

- Ensure proper ventilation during application

- Contact local distributors for assistance

First-Aid Measures

- Skin contact: Wash with plenty of water

- Eye contact: Rinse with water and seek medical help

- Inhalation: Move to fresh air, seek medical attention if needed

- Ingestion: Induce vomiting and seek medical help

Fire-Fighting Measures

- Hazardous combustion products: CO, CO2

- Fire extinguishing media: Dry powder, CO2, sand

KAIDA JINYU PAINT Water-based Polyurethane Floor Project