Description

Product Overview

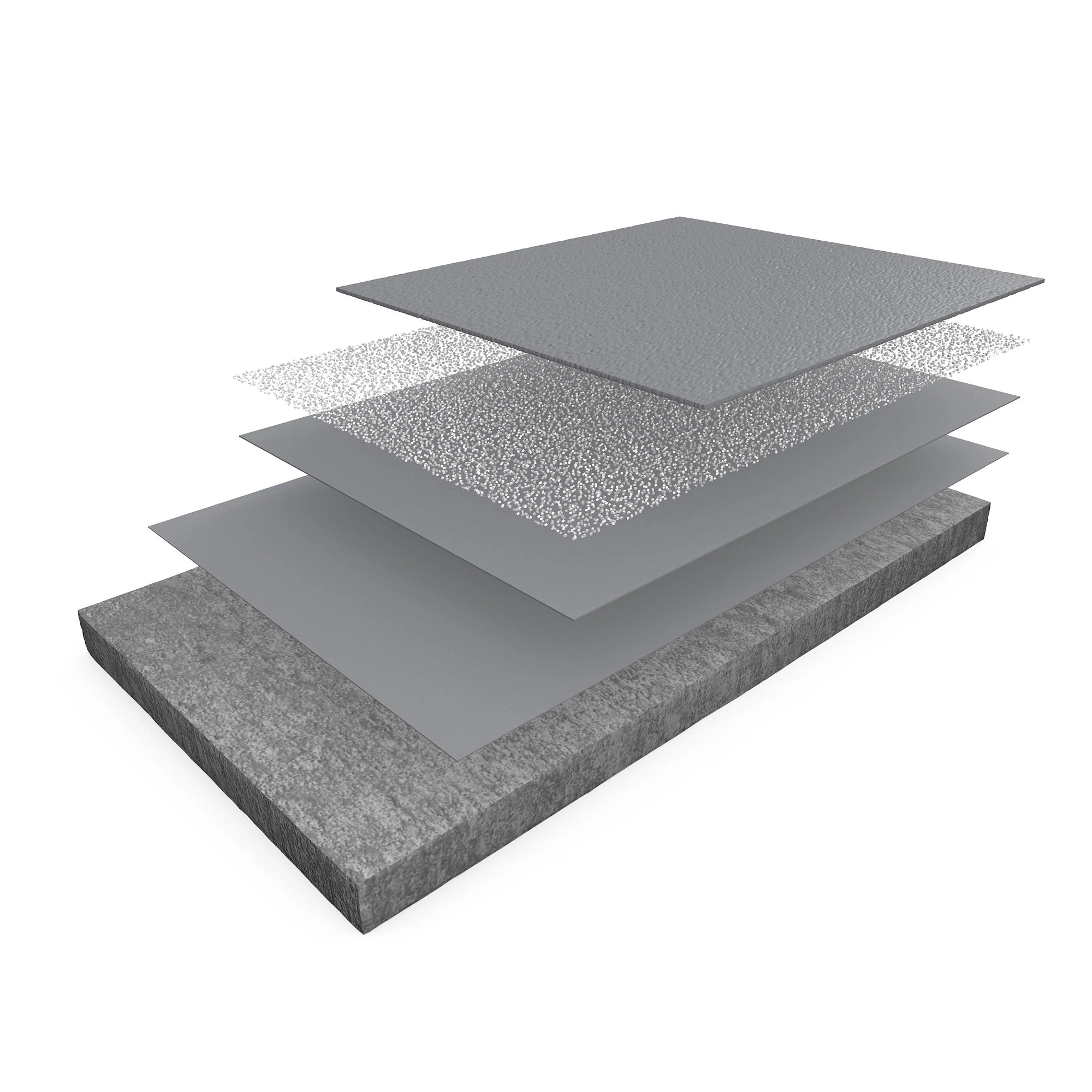

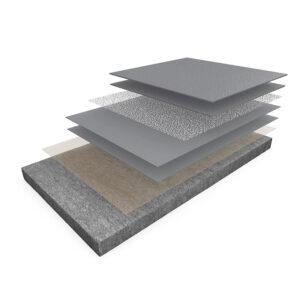

ResdeckPro™ III is an elastomeric, heavy-duty decking system designed for new or old concrete in need of waterproofing and repair. This innovative flooring solution comprises a primer, a unique elastomeric urethane basecoat/membrane broadcast with silica sand for a stratified finish, followed by an aliphatic, UV-stable polyurea topcoat. The system delivers exceptional durability, chemical resistance, and crack-bridging capabilities, making it the ideal coating for protecting balconies, parking garages, walkways, and industrial floors from weathering, chemical exposure, and structural movement.

User Pain Points & Scenario Analysis

Industrial and commercial flooring faces constant challenges. Common issues include:

Cracking & Spalling: Freeze-thaw cycles and structural movement cause traditional cement and mortar surfaces to crack, leading to water infiltration and costly repairs.

Chemical Damage: Oil, grease, deicing salts, and other chemicals degrade standard paint and epoxy finishes, causing discoloration and breakdown.

Wear & Tear: Heavy pedestrian and vehicular traffic leads to rapid abrasion and deterioration of non-reinforced surfaces.

Slip Hazards: Wet conditions on smooth surfaces create dangerous environments, necessitating reliable anti-slip solutions.

Water Infiltration: Leaking decks over occupied spaces cause interior damage and mold, demanding a truly waterproof sealer.

Specific Scenarios:

Parking Garages: Require a coating that withstands tire traffic, salts, oils, and provides a textured, anti-slip finish.

Balconies & Walkways: Need a flexible, waterproof system that accommodates thermal expansion and prevents leaks to spaces below.

Industrial Facilities: Demand a flooring solution resistant to chemical spills, impact, and heavy loads while being easy to clean.

Product Solution & Key Features

ResdeckPro™ III directly addresses these pain points with its engineered polyurethane system:

Superior Waterproofing & Elastomeric Performance: The urethane membrane bridges cracks up to 1/16″, expands and contracts with substrate movement, and forms a seamless, impermeable barrier.

Exceptional Durability: With high tensile strength and tear resistance, it withstands moderate to heavy traffic, impact, and abrasion, ensuring a long finish life.

Enhanced Safety: The broadcast aggregate within the system creates a permanent, textured surface for outstanding anti-slip performance, even when wet.

Chemical & UV Resistance: The aliphatic polyurea topcoat resists a wide range of chemicals, oils, and fuels, and provides superior color and gloss retention under sunlight, unlike standard epoxy.

Rapid Return to Service: The system allows light foot traffic within 24 hours and full service within 72 hours, minimizing downtime for contractors and property owners.

Proven System Integrity: A unified, stratified coating system from a single manufacturer ensures compatibility and performance, backed by comprehensive technical data.

Technical Specifications & Authoritative Data

| Property | Test Method | ResdeckPro™ FHS (Basecoat/Membrane) | ResdeckPro™ FLA (Topcoat) |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 60 ± 5 | 85 ± 5 |

| Tear Resistance (Die C) | ASTM D624 | 250 ± 25 pli | 300 ± 10 pli |

| Tensile Strength | ASTM D412 | 1350 ± 150 psi | 3200 ± 10% psi |

| Ultimate Elongation | ASTM D412 | 675 ± 10% | 450 ± 10% |

| Water Absorption | ASTM D471 | 0.05% by weight | 1.30% by weight |

| VOC Content (Mixed) | ASTM D2369 | < 100 g/L | < 100 g/L |

| Theoretical Coverage | – | 30-50 sq ft/gal | 80 sq ft/gal (1st coat) |

Application Areas

ResdeckPro™ III is the specified solution for a wide range of commercial and industrial applications:

Parking Structures (Decks, Ramps, Drive Lanes)

Pedestrian Areas (Balconies, Terraces, Walkways, Breezeways)

Roof Decks & Plazas

Mezzanines & Mechanical Rooms

Industrial & Commercial Flooring over concrete and metal

Installation Process & Technical Support

Professional installation is key to system performance. The key steps are:

Surface Preparation: Concrete must be abrasive blasted to a CSP 3-4 profile, clean, sound, and dry (meeting strict moisture vapor emission standards).

Primer Application: Apply ResdeckPro™ FLP/E primer to ensure adhesion.

Basecoat/Membrane & Broadcast: Apply the ResdeckPro™ FHS urethane basecoat and broadcast 16/30 mesh silica sand into the wet film to create the reinforced, textured layer.

Topcoat Application: Apply the durable, UV-stable ResdeckPro™ FLA polyurea topcoat. A second topcoat is recommended for high-traffic areas like ramps.

Our Commitment: We provide more than just products. Our team offers specification support, detailed installation instructions, and access to a network of approved, experienced contractors to ensure your project’s success.

Frequently Asked Questions (FAQ)

Q: What is the difference between ResdeckPro™ III and a standard epoxy flooring system?

A: While both are durable, ResdeckPro™ III is a flexible urethane system with far superior UV resistance (no yellowing), better thermal stability for exterior use, and higher elasticity for crack bridging. Epoxy systems are typically more rigid and can chalk or degrade under direct sunlight.

Q: How long does the ResdeckPro™ III urethane flooring installation take?

A: The installation timeline depends on area size and conditions. Typically, the coating process itself can be completed over a few days. Light foot traffic is permitted after 24 hours, with full vehicular traffic allowed after 72 hours.

Q: What maintenance is required for a polyurethane floor coating?

A: Maintenance is simple. Regular sweeping and occasional washing with a mild detergent and a bristle brush (for textured surfaces) or power washer is sufficient. Avoid harsh solvents and immediate cleanup of oil spills is recommended to maintain appearance and slip resistance.

Q: What is the minimum temperature for applying this polyurethane concrete sealer?

A: The substrate temperature should be between 60°F and 90°F (15°C – 32°C) and at least 5°F above the dew point during application.

Trust & Proof

ResdeckPro™ III is backed by extensive laboratory testing against ASTM standards, ensuring performance data is reliable and repeatable. It is a proven system specified by architects and engineers for major commercial projects across North America. We encourage you to review our technical data sheets and request project references.

KAIDA PAINT Brand Introduction

Looking for a reliable, high-performance urethane flooring solution?

KAIDA PAINT is a leading innovator in advanced industrial coating solutions, specializing in high-performance urethane and polyurethane technologies. We are more than a manufacturer—we are your dedicated partner in protecting and enhancing surfaces that endure the toughest conditions.

Our products, like the ResdeckPro™ III flooring system, are engineered through deep market insight and rigorous testing. We deliver not only premium formulations but complete project success—offering unparalleled technical support, specification guidance, and access to a network of certified installers.

We partner with contractors, facility managers, and project owners to achieve durable, cost-effective, and visually impressive results. Let KAIDA PAINT help you solve your next flooring challenge. Contact our team for a consultation today.

Why Choose KAIDA PAINT?

Expert Formulations: We develop urethane and polyurethane systems for maximum durability and value.

Technical Partnership: Get expert guidance on system selection, installation best practices, and troubleshooting.

Contractor Network: We can connect you with certified, experienced installers in your region.

Ready to specify or install the best polyurethane floor coating for your next project? Contact our flooring experts today for a detailed quote, technical consultation, or to find an approved installer near you.