Why KAIDA PAINT is the Ideal Choice for Brewery & Distillery Flooring

KAIDA PAINT high-build epoxy and polyurethane resin flooring systems are the professional-grade solution for craft breweries, multinational distilleries, hard seltzer production lines, and beverage packaging halls. Whether you are a commercial contractor installing a new microbrewery floor or a facility manager repairing a failed sealer in an aging distillation room, KAIDA PAINT delivers the chemical resistance, thermal stability, and hygienic finish your operation requires.

Challenges & Environmental Demands in Brewery and Distillery Facilities

Beverage production floors undergo abuse from multiple aggressive forces simultaneously. A single shift may expose the flooring to:

Thermal shock: Frequent washdowns with 180°F water followed by ambient drying create rapid expansion and contraction cycles that crack brittle cement or low-quality paints.

Chemical corrosion: Daily application of peracetic acid, quaternary ammonium compounds, sodium hypochlorite, and nitric-based sanitizers can etch concrete and dissolve inferior epoxy resins.

Hydrostatic pressure: Standing water and condensate from cold storage areas penetrate unsealed slabs, leading to adhesive failure of tile or sheet vinyl systems.

Mechanical impact: Dropped kegs, forklift traffic, and the constant roll of stainless steel barrels chip and scuff unprotected concrete.

Biological contamination: Spilled wort, yeast slurry, and high-sugar liquids create breeding grounds for Listeria, mold, and fungi if the floor contains cracks, grout lines, or unsealed cold joints.

Additionally, facilities must meet rigorous standards. Floors must be USDA-compliant for meat and beverage contact areas and ready for FDA inspection. KAIDA PAINT systems are formulated to meet these federal requirements without relying on waxes or temporary topical coatings that mask rather than solve contamination risks.

Engineered for Every Beverage Production Pain Point

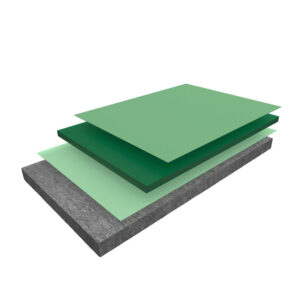

KAIDA PAINT does not offer a single “brewery paint” and expect it to perform everywhere. Instead, we provide a complete system—from primer to topcoat—where each layer serves a specific protective function.

100% solids epoxy basecoat → eliminates volatile organic compounds and fills surface voids. Unlike latex or water-based acrylics that shrink during cure, our high-build epoxy basecoats self-level to fill hairline cracks and bug holes, preventing bacteria from finding a home beneath the finish.

Anti-microbial polymer technology → actively inhibits pathogen proliferation. The resin matrix incorporates EPA-registered antimicrobial agents that suppress the growth of mold, mildew, and gram-positive bacteria on the floor surface.

Slip-resistant urethane topcoat → maintains traction even under wet or yeasty conditions. We engineer the coefficient of friction into the finish, not as an afterthought spray-on additive that wears off. Silica-modified textures provide OSHA-compliant slip resistance while remaining easy to clean.

Thermal shock-resistant polyurethane → withstands rapid temperature swings. Our polyurethane topcoats and polyurethane cement systems absorb the stress of hot-cold-hot cycles without delaminating from the substrate.

Seamless, monolithic finish → eliminates harbor points for spoilage organisms. There are no grout lines to re-grout, no vinyl tile edges to lift, and no adhesive to dissolve. The floor becomes one continuous piece of protection.

Chemical-resistant shield → protects against pH extremes. From the low pH of citric acid in kettle houses to the high pH of caustic CIP solutions, the KAIDA PAINT system acts as a polymer shield between your expensive industrial equipment and the corrosive liquids on the floor.

Beyond Durability to Operational Excellence

Installing KAIDA PAINT brewery flooring is not just a maintenance decision; it is a strategic investment in productivity and brand protection.

Sanitation efficiency: The non-porous, high-gloss finish allows water to sheet off completely. Cleaning crews spend less time scrubbing and more time on value-added tasks. The floor dries faster, reducing the risk of slips and allowing production to resume sooner.

Audit readiness: When inspectors walk your facility, they see a seamless, stain-free, light-reflective surface. This visual evidence of cleanliness helps your company demonstrate compliance with FSMA and HACCP protocols.

Long-term cost control: While the initial price of a high-performance resin system is higher than a can of garage floor paint, the total cost of ownership is dramatically lower. You avoid annual repairs, patchwork re-sealing, and the hidden cost of product recalls linked to floor-sourced contamination.

Aesthetic versatility: Unlike basic gray cement or industrial epoxy, KAIDA PAINT offers a wide shade range and decorative flake systems. Public-facing tasting rooms and taprooms can display the same durable finish as the production floor, maintaining brand consistency without sacrificing performance.

Who Needs Brewery & Distillery Flooring?

The decision to specify a proper brewery floor impacts multiple stakeholders.

Facility Managers and Operations Directors need a floor that can stand up to 24/7 production schedules without requiring constant repair or “weekend patching.”

Compliance and Safety Officers require documented proof that the flooring system meets NSF/ANSI Standard 61 and does not contribute to biological contamination.

Contractors and Installers need a system that applies predictably, cures reliably, and does not generate callbacks due to adhesion failure or amine blush.

Owners and Executives understand that a failed floor can halt production, delay shipments, and damage the brand’s reputation. They invest in protection that keeps the beer flowing and the whiskey barreling.

KAIDA PAINT protects the floors, the products, and the employees that depend on a safe, sanitary work surface every shift.

KAIDA PAINT Flooring Solutions: A Complete System Backed by Experience

KAIDA PAINT is not a generalist paint manufacturer; we are a specialized industrial flooring company serving commercial and industrial clients across China and global markets. Our brewery and distillery systems are the result of years of field application in some of the harshest food and beverage environments.

We do not simply supply a resin kit and walk away. We provide detailed technical data, system recommendations based on your specific traffic levels and chemical exposure, and support for your installation contractor from basecoat preparation through final topcoat. Whether you require a low-build sealer for a low-traffic barrel storage room or a heavy-duty polyurethane cement system for a high-impact brew house, KAIDA PAINT is the manufacturer that delivers the right solution.

Contact us today to learn more about our brewery and distillery flooring systems and receive a specification package tailored to your facility.