Application

KAIDA PAINT high-build resin flooring systems are the ideal choice for modern printing and packaging facilities. From high-speed label printing presses to automated packaging lines for e-commerce giants, our flooring provides a monolithic, high-performance surface that integrates seamlessly with the industrial rhythm.

Challenges & Environmental Demands in Printing & Packaging Facilities

The concrete slab in a printing plant undergoes abuse from a unique combination of aggressive elements that standard commercial flooring, such as vinyl tile or basement epoxy kits, cannot withstand. These floors:

Are subject to frequent chemical attack from liquid ink spills, petroleum-based solvents, cleaning alcohols, and adhesive residues.

Undergo abuse from heavy point loads and vibrations from double-wide printing presses and high-reach forklifts.

Must withstand thermal shock caused by steam cleaning or the sudden pour of hot liquids used in equipment maintenance.

Are exposed to constant pigment staining, requiring aggressive stripping agents that can degrade cheap paint finishes.

Must meet strict OSHA safety standards and FDA/GMP guidelines for slip resistance and foreign material control, preventing contamination of open packaging materials.

Product Features: Engineering Precision for Industrial Abuse

KAIDA PAINT does not offer a simple garage floor kit; we provide a comprehensive architectural coating system designed to outperform generic epoxy or polyurethane products.

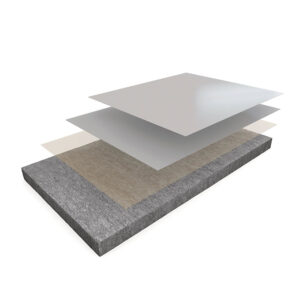

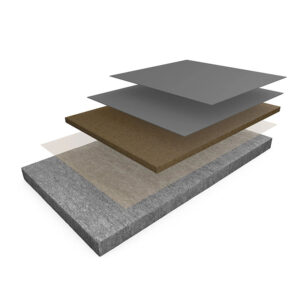

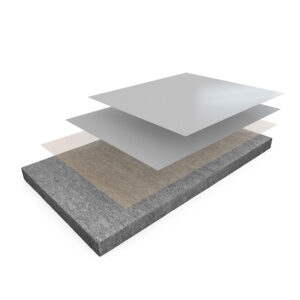

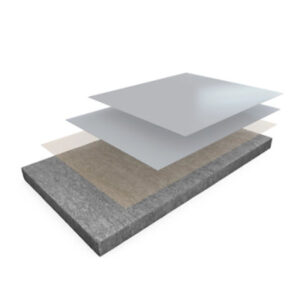

100% Solids Epoxy Basecoat → We do not use water-based or latex primers that require “breathing.” Our high-build impregnation sealers fill concrete cracks and surface pores, creating a hydrostatic pressure-resistant barrier that prevents moisture vapor transmission.

Anti-Slip Aggregate Infusion → Unlike polished concrete or a standard gloss finish that becomes slippery when wet, we integrate aluminum oxide or polymer-modified silica into the topcoat. This provides a high “Slip” resistance coefficient (anti-slip) even when covered in liquid ink.

UV-Stable Polyurethane Topcoat → While standard epoxy will chalk and amber under warehouse light or sunlight near dock doors, our polyurethane finish (poly) retains its color and gloss. It acts as a sacrificial shield, protecting the underlying color coat from abrasion.

Seamless Chemical Shield → There are no grout lines or sheet seams for bacteria to hide. The monolithic resin system creates a liquid-tight treatment, preventing rust on metal equipment legs and standing up to acetic acid and alkali cleaners.

Thermal Shock & Impact Resistance → The flexibility of our urethane technology ensures the floor does not crack when heavy parts are dropped or when hot presses are moved.

Lowering Total Cost of Ownership

Selecting KAIDA PAINT moves the facility manager beyond mere aesthetics and into strategic asset protection.

Operational Efficiency: The high-gloss, mirror-like finish reflects light, reducing lighting costs in the warehouse by up to 30%. This white, clean environment boosts employee morale and productivity.

Compliance & Safety: By meeting ADA and OSHA requirements for dry and wet slip resistance, we help companies avoid costly litigation and worker compensation claims.

Cost Reduction: While the initial price per square foot may be higher than applying a simple stain or wax, the lifecycle cost is dramatically lower. There is no need to strip and reapply annually. Our systems provide a 10-15 year functional lifespan, eliminating the recurring costs seen with vinyl composition tile or acrylic sealers.

Who Needs Printing Flooring Solutions?

This solution is specifically engineered for Plant Facility Managers, Corporate EHS Directors, and Commercial Contractors. If your team currently spends weekends cleaning and polishing a floor that never looks clean, or if you are preparing for a FDA audit and are concerned about ink absorption into the concrete, you need this system. It protects the floors, the expensive printing equipment, and the employees navigating the high-speed logistics environment.

Why KAIDA PAINT Flooring Solutions?

As a professional manufacturer based in China, KAIDA PAINT combines advanced polymer technology with rigorous quality control. We are not a DIY brand for residential basements; we are an industrial-grade supplier for companies and contractors. Our systems are available in a wide range of colors and custom shades, allowing you to display your brand identity or designate specific safety zones (red for danger, yellow for walkways, green for finished goods). Whether you require a super-heavy-duty system for a factory floor or a decorative high-build system for a showroom, KAIDA PAINT is the professional Installer’s preferred supply.

Stop comparing “epoxy vs urethane” or “resin vs tile” reviews online. Contact us today to learn more about our printing and packaging flooring solutions. Request free samples, a detailed project cost estimate, or a consultation with our technical team to specify the correct system for your specific application.