1. Introduction

Epoxy flooring is widely used in garages, factories, and warehouses due to its durability, sleek appearance, and easy maintenance. However, it’s not a perfect solution for every situation. This article explores the 7 key drawbacks of epoxy flooring to help you decide if it meets your needs. This expert guide reveals:

- Better flooring alternatives

- The 7 most common epoxy floor disadvantages

- When you should avoid epoxy coatings

- Professional solutions for each problem

2. Slippery Surface: Safety Risks

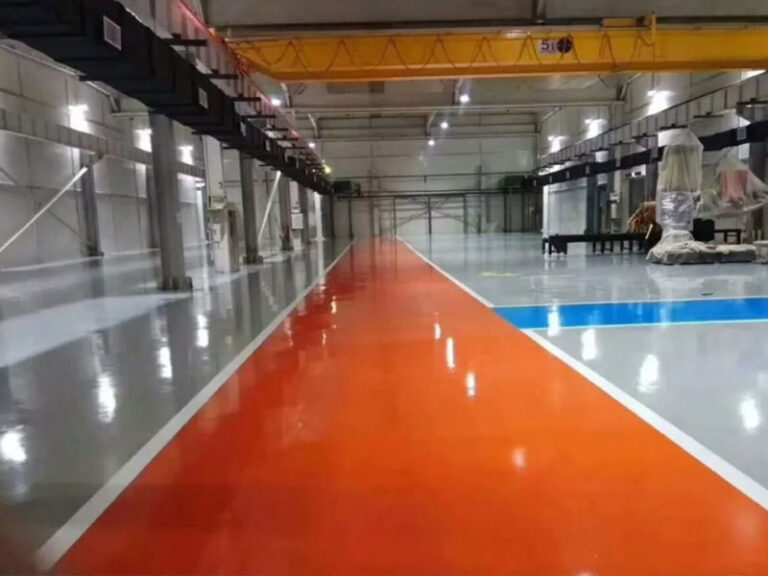

One of the biggest complaints about epoxy flooring is that it becomes extremely slippery when wet, increasing the risk of accidents.

Key Issues

- High risk in areas exposed to water, oil, or chemicals (e.g., garages, workshops).

- Glossy finishes worsen traction issues.

Solutions

- Use anti-slip epoxy coatings (with quartz sand or aluminum oxide additives).

- Apply textured finishes for better grip.

3. UV Damage and Yellowing (Outdoor Use Problems)

Standard epoxy flooring fades, yellows, or chalks when exposed to direct sunlight, making it unsuitable for outdoor applications.

Key Issues

- Significant color degradation within 1–2 years in sunny areas.

- Not ideal for driveways, patios, or pool decks.

Solutions

- Opt for UV-resistant epoxy or a polyurethane topcoat.

- Consider alternative materials like polyurea flooring for outdoor use.

4. Difficult and Expensive Repairs

Unlike tiles or concrete, damaged epoxy floors are hard to repair seamlessly.

Key Issues

- Peeling, chipping, or bubbling often requires full recoating.

- Spot repairs are noticeable due to color mismatch.

Solutions

- Invest in high-quality epoxy to minimize future repairs.

- For minor damage, use epoxy floor patch kits.

5. Long Installation and Curing Time

Epoxy flooring isn’t a quick-install solution—proper application requires 3–7 days before full use.

Key Issues

- Surface prep (grinding, cleaning) is time-consuming.

- Curing delays can disrupt business operations or home use.

Solutions

- Plan installation during downtime.

- Choose fast-curing epoxy (walkable in 24 hours).

6. High Upfront Cost

Epoxy flooring has a higher initial cost compared to basic concrete or paint.

Cost Comparison

| Material | Avg. Cost per Sq. Ft. |

|---|---|

| Standard Epoxy | $3–$8 |

| Polished Concrete | $2–$5 |

| Garage Floor Tiles | $4–$10 |

Is It Worth It?

- Long-term durability (15+ years) may justify the cost for high-traffic areas.

7. Strong Odors and VOCs During Installation

Epoxy resin releases volatile organic compounds (VOCs), causing strong fumes during curing.

Key Issues

- Health risks for sensitive individuals (headaches, respiratory irritation).

- Requires 48+ hours of ventilation before safe occupancy.

Solutions

- Use low-VOC or water-based epoxy.

- Wear protective gear during application.

8. Not DIY-Friendly

Poor installation (common with DIY attempts) leads to peeling, bubbles, or uneven coatings.

Common DIY Mistakes

- Inadequate surface prep → adhesion failure.

- Incorrect epoxy mixing ratio → improper curing.

Recommendation

- Hire professional epoxy floor installers for best results.

9. Conclusion: Should You Choose Epoxy Flooring?

Best For:

- High-traffic industrial spaces.

- Indoor use (garages, basements).

Worst For:

- Outdoor UV-exposed areas.

- Budget-conscious projects.

Top Alternatives: Polyurea, polished concrete, PVC tiles.

Final Tip: Consult a local epoxy flooring contractor for personalized advice.