Description

Product Overview

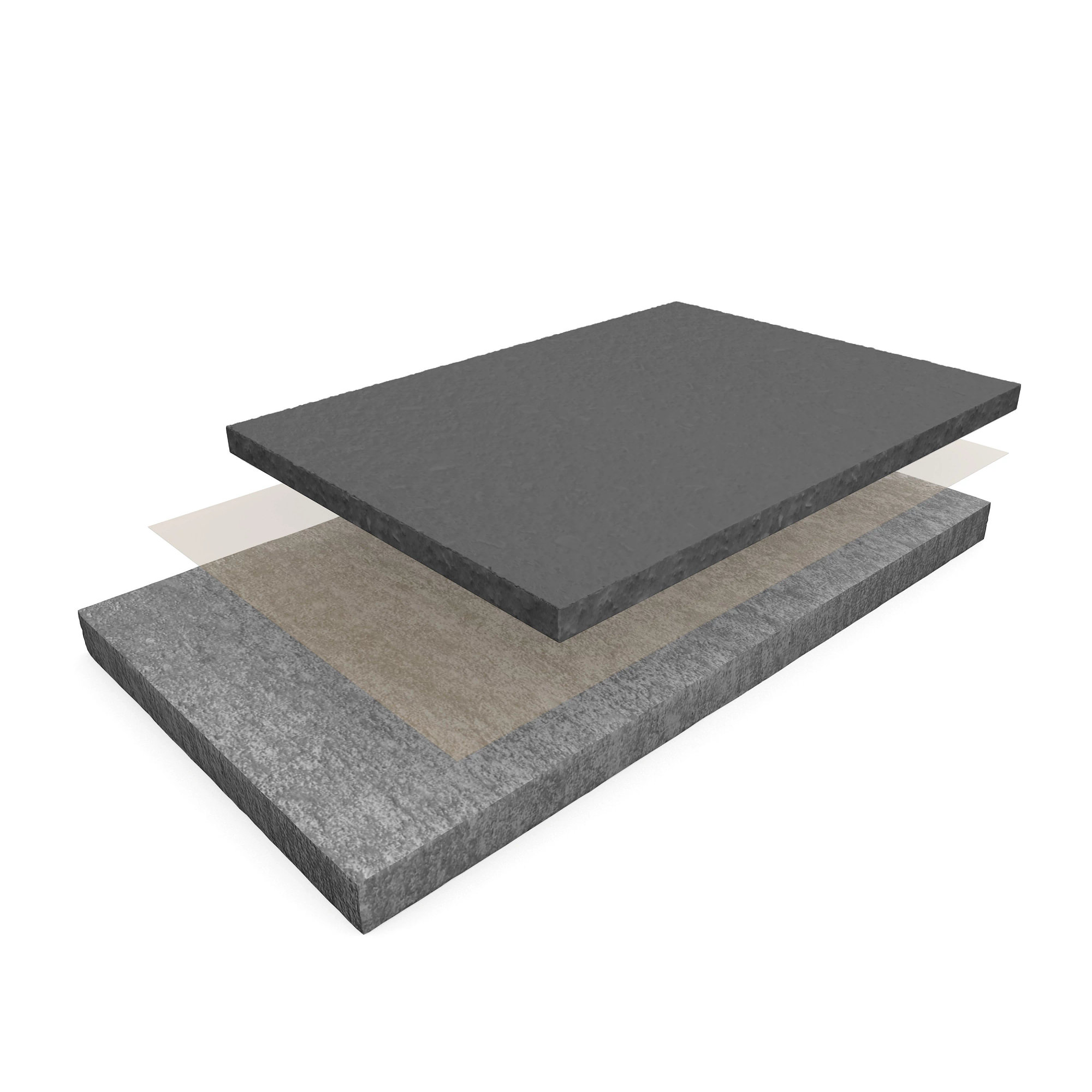

Ure-Crete™ MD is a high-performance, 100% solids, self-leveling cementitious urethane concrete coating system designed for demanding industrial and commercial environments. By combining advanced aromatic polyurethane resins with graded silica aggregates and fine fillers, it forms a seamless, monolithic flooring solution. The system exhibits exceptional durability, thermal shock resistance, and a uniform matte finish. As a self-priming system, it simplifies installation by eliminating the need for a separate topcoat. Ure-Crete™ MD is engineered to withstand heavy traffic, chemical exposure, and significant thermal cycling, providing a long-lasting, low-maintenance flooring surface for warehouses, manufacturing facilities, pharmaceutical plants, and other high-traffic areas.

The Industrial Flooring Challenge: Common Pain Points

Choosing the right flooring solution is critical for contractors, facility managers, and companies across industries. Common problems with traditional concrete or inferior coating systems include:

Durability Issues: Cracking, chipping, and dusting under heavy forklift or pallet jack traffic, leading to frequent repairs and downtime.

Chemical Damage: Staining, etching, and degradation from oils, fats, acids, alkalis, and cleaning products common in food & beverage, automotive, and industrial settings.

Moisture Problems: Blistering and delamination caused by hydrostatic pressure or high moisture vapor emission rates (MVER) from slabs-on-grade.

Hygiene & Cleanability: Porous surfaces that harbor bacteria, mold, and dirt, failing to meet stringent sanitation standards required in pharmaceuticals, healthcare, and dry goods manufacturing.

Aesthetic & Safety Failures: Faded, yellowed, or slippery surfaces that are unsightly and pose safety risks.

These challenges result in increased long-term cost, operational disruptions, and potential compliance failures.

The Ure-Crete™ MD Solution: Engineered for Performance

Our cementitious urethane flooring system is specifically formulated to address these pain points. Here are its core advantages:

1. Unmatched Mechanical Durability

Ure-Crete™ MD is a robust urethane mortar designed to last. Its physical properties surpass ordinary concrete and many epoxy systems.

High Abrasion & Impact Resistance: With a Taber Abrasion loss of only 50mg (CS-17 Wheel, 1000 cycles, ASTM D-4060) and impact resistance >160 in-lbs, it withstands the punishment of constant industrial traffic.

Exceptional Strength: Features a compressive strength of 8,990 psi and flexural strength of 5,075 psi, preventing cracks and deformation under heavy loads.

Thermal Shock Resistant: Its coefficient of thermal expansion is similar to concrete, making it ideal for environments with rapid temperature changes or thermal cycling, such as freezer-to-room transitions.

2. Superior Chemical & Moisture Tolerance

This system provides a reliable barrier against a wide range of substances.

Moisture Mitigation: Can be installed on substrates with moisture levels up to 99% Relative Humidity (ASTM F-2170), mitigating risks associated with slab moisture.

Broad Chemical Resistance: The dense, non-porous finish resists many oils, greases, dilute acids, and alkalis, simplifying cleaning and maintenance. (For specific chemical exposures, consult our Chemical Resistance Guide).

3. Seamless, Hygienic & Safe Surface

100% Solids, Seamless Finish: Creates a monolithic surface with no grout lines or seams, eliminating areas for dirt, moisture, and bacteria to collect.

Easy to Clean: The smooth, non-absorbent surface allows for quick wash-downs and sterilization.

Enhanced Safety: Offers a static coefficient of friction >0.6 (ASTM D-2047), providing a slip-resistant surface even when wet.

4. Practical & Sustainable Benefits

Self-Priming & No Topcoat Required: The system simplifies the installation process, reducing labor time and material cost.

Low VOC & Indoor Air Quality Compliant: Contains 0 g/L VOC and complies with stringent indoor air quality standards like CA 01350, ensuring a safe environment for occupants.

Long-Lasting Value: Reduces the total lifecycle cost by minimizing the need for repairs, recoating, and frequent deep cleaning.

Technical Specifications & Data

The performance of Ure-Crete™ MD is backed by rigorous testing against international standards.

| Property | Test Method | Result / Value |

|---|---|---|

| System Type | – | 100% Solids, Cementitious Urethane |

| Thickness | – | 3/16″ – 1/4″ (Nominal) |

| Hardness | ASTM D-2240 (Shore D) | 85 |

| Compressive Strength | ASTM C-579 | 8,990 psi |

| Tensile Strength | ASTM D-638 | 2,175 psi |

| Flexural Strength | ASTM D-790 | 5,075 psi |

| Abrasion Resistance | ASTM D-4060 (CS-17 Wheel) | 50 mg loss |

| Impact Resistance | MIL D-3134 @ 125 mils | > 160 in-lbs |

| Slip Resistance | ASTM D-2047 (Static CoF) | > 0.6 |

| VOC Content | – | 0 g/L |

| Pot Life (@ 70°F) | – | Approximately 15 minutes |

Ideal Applications

Ure-Crete™ MD is the solution of choice for diverse sectors requiring robust and reliable flooring:

Warehousing & Logistics: Withstands constant heavy cart and forklift traffic.

Food & Beverage Processing: Resists thermal shock from washdowns and chemical exposure from sanitizers.

Pharmaceutical & Life Sciences: Meets hygiene requirements with a seamless, cleanable surface and IAQ compliance.

Manufacturing & Production Areas: Handles impact from dropped tools and parts, and resists oils and coolants.

Automotive Facilities: Durable against tire traffic, chemical spills, and heavy equipment.

Commercial Kitchens & Breweries: Excellent thermal shock resistance for areas with hot/cold transitions and frequent cleaning.

Professional Installation & Support

A flawless finish depends on expert installation. KAIDA PAINT provides comprehensive support for contractors and companies.

Key Installation Steps:

Surface Preparation: Critical step involving shot blasting to a CSP 3-5 profile, ensuring a clean, sound, and profiled concrete substrate.

Primer Application: Using a compatible primer on prepared surfaces to ensure optimal adhesion.

Material Mixing & Pouring: Combining the urethane resin, hardener, and aggregate in strict ratios using low-speed, high-torque drills.

Spreading & Leveling: Pouring the mixed material and spreading it to the specified thickness using a pin rake.

Deaeration & Finishing: Immediately rolling with a spiked roller to release air bubbles and create a smooth surface.

Curing: Allowing proper cure time (min. 10-24 hrs for foot traffic) based on ambient temperature.

Our Technical Support Includes: Pre-installation site audits, detailed specification guidance (like ASTM standards), on-site technician support, and troubleshooting assistance to ensure your project’s success.

Frequently Asked Questions (FAQ)

What is the difference between a cementitious urethane and an epoxy floor?

While both are durable, cementitious urethane systems like Ure-Crete™ MD offer superior flexibility, thermal shock resistance, and UV stability compared to most epoxies. This makes urethane floors less prone to cracking from substrate movement and yellowing when exposed to sunlight or metal halide lighting.

How long does it take to install Ure-Crete™ MD?

The installation timeline depends on the area size and site conditions. Typically, after surface prep, the material itself can be poured and finished rapidly due to its self-leveling nature. The area can often accept light foot traffic in 10-24 hours at 70°F.

Can Ure-Crete™ MD be applied over existing concrete with moisture issues?

Yes. A key advantage is its high moisture tolerance. It can be installed on slabs with up to 99% relative humidity (per ASTM F-2170), making it an excellent choice for many existing slabs where moisture mitigation is a concern.

What maintenance is required for a cementitious urethane floor?

Maintenance is simple. Regular sweeping and occasional damp mopping with a neutral pH cleaner are usually sufficient. Avoid harsh abrasive cleaners. The system’s density and chemical resistance mean it does not require waxing or a protective sealer.

Why Choose KAIDA PAINT?

KAIDA PAINT stands at the forefront of high-performance industrial flooring solutions. For decades, we have dedicated ourselves to formulating and supplying advanced coating systems that meet the rigorous demands of modern commerce and industry. We understand that your floor is a critical asset—it impacts safety, productivity, maintenance cost, and operational continuity.

Unlike generic suppliers, we specialize in engineered systems like the Ure-Crete™ MD cementitious urethane flooring. Our products are the result of intensive R&D and real-world feedback from contractors and facility managers. We don’t just sell paint; we deliver a comprehensive solution backed by:

Deep Technical Expertise: Our support team helps with specification, moisture testing interpretation, and installation best practices.

Proven Performance: Our formulations are tested to international standards (ASTM, ISO) to ensure they perform as promised.

Partnership Approach: We work closely with companies and contractors from project conception to completion, ensuring optimal results.

Choosing KAIDA PAINT means investing in a floor built to last, supported by a partner committed to your success. Let’s discuss how Ure-Crete™ MD can solve your flooring challenges. Contact our team for a detailed consultation, project specification support, or a competitive quote.