Description

Product Overview

ResuShield™ XT Topcoat is a multi-coat, solvent-based or 100% solids epoxy flooring system designed for extreme durability. By combining advanced epoxy resin technology with reinforced polymers, it forms a monolithic, non-porous shield over your concrete substrate. This system exhibits exceptional resistance to abrasion, impact, chemicals, and moisture, ensuring long-term protection. It provides a seamless, glossy finish that is easy to clean and maintain, making it the ideal solution for industrial facilities, warehouses, manufacturing plants, and commercial garages where performance and hygiene are critical.

Common Industrial Flooring Problems & How ResuShield™ XT Solves Them

Industrial and commercial floors face constant abuse. Without a proper protective coating, bare concrete is susceptible to a host of issues that disrupt operations, incur high repair costs, and create safety hazards.

Dusting & Degradation: Untreated concrete creates dust (laitance), contaminating products and machinery and degrading air quality. Our Solution: ResuShield™ XT seals the concrete surface completely, creating a dust-proof barrier that is easy to clean with standard industrial cleaning solutions.

Cracks & Spalling: Heavy loads, impact, and freeze-thaw cycles cause cracks and surface breakdown. Our Solution: The system’s high tensile strength and excellent adhesion to the cement substrate bridge minor cracks and prevent further spalling, extending the floor’s lifecycle.

Chemical Attack & Stains: Floors in automotive, food & beverage, or chemical plants are exposed to oils, acids, solvents, and sugars that stain and etch concrete. Our Solution: ResuShield™ XT offers superior chemical resistance, protecting your substrate from corrosive substances and allowing for quick spill cleanup.

Abrasion & Wear: Constant foot and vehicular traffic, especially from metal parts or pallets, rapidly wears down flooring. Our Solution: With an exceptionally high Taber Abrasion resistance rating, this topcoat maintains its integrity and appearance under heavy traffic, outperforming standard epoxy paint.

Moisture & Vapor Transmission: Moisture from the concrete slab can cause coating failure, leading to bubbling and delamination. Our Solution: Proper system design with specialized primers allows ResuShield™ XT to be applied in environments with moderate moisture vapor transmission rates, preventing future failure.

Hygiene & Cleanliness Challenges: Porous concrete harbors bacteria and is difficult to sanitize, a critical issue for USDA-inspected facilities, kitchens, and labs. Our Solution: The seamless, non-absorbent finish provides no place for microbes to hide, meeting stringent sanitary requirements and allowing for effective cleaning with water and appropriate chemicals.

Product Solutions & Key Features

The ResuShield™ XT Topcoat system is more than just a floor paint; it’s a comprehensive engineered solution. Here are its core selling points:

1. Unmatched Mechanical & Physical Performance:

Extreme Abrasion Resistance: Formulated to resist wear from steel wheels, forklifts, and heavy foot traffic.

High Impact Resistance: Absorbs shocks from dropped tools or equipment without cracking or chipping.

Seamless & Durable Finish: Creates a monolithic surface without grout lines or seams where dirt can accumulate.

Slip-Resistance Options: Available in various gloss levels and can be specified with anti-slip aggregates (flakes) for areas like commercial kitchens, bathrooms, or pool decks to meet safety standards.

2. Superior Chemical & Stain Resistance:

Resists a wide range of chemicals including diluted acids, alkalis, oils, greases, and salts.

Non-porous surface prevents staining from most common industrial substances, allowing for easy stain removal.

3. Aesthetic Versatility & Customization:

Color Selection: Available in a wide spectrum of standard and custom colors (grays, whites, blues, greens, etc.) to match your corporate identity or functional zoning needs.

Finish Options: Choose from high-gloss, semi-gloss, or satin finishes to suit the application, from a bright showroom floor to a low-glare factory setting.

Decorative Effects: Can be combined with color quartz chips or vinyl flakes to create attractive, slip-resistant surfaces for retail spaces, showrooms, or residential basements.

4. Efficient Application & Sustainability:

Rapid Cure Times: Minimizes facility downtime, allowing a quicker return to service.

Professional Installation Recommended: For best results, application by approved, experienced contractors is advised to ensure proper surface prep (concrete grinding, crack repair) and system performance.

Low VOC Options: Available formulations help projects meet indoor air quality requirements and environmental regulations.

Technical Data & Specifications

The following table presents key performance data for the ResuShield™ XT Topcoat system, based on standard laboratory testing methods (ASTM, ISO). Specific values may vary based on substrate condition, application thickness, and environmental factors.

| Property | Test Method | Typical Value/Result | Benefit |

|---|---|---|---|

| Compressive Strength | ASTM D695 | > 10,000 psi | Withstands heavy static loads from machinery and storage racks. |

| Tensile Strength | ASTM D638 | > 3,000 psi | Resists cracking and provides cohesive strength within the coating. |

| Flexural Strength | ASTM D790 | > 6,000 psi | Maintains integrity under bending or flexing stresses. |

| Adhesion to Concrete | ASTM D4541 / Pull-Off | > 500 psi (Cohesive failure in concrete) | Ensures the coating system bonds permanently to the substrate. |

| Abrasion Resistance | ASTM D4060 (Taber Abraser) | < 40 mg weight loss (CS-17 wheel, 1000g, 1000 cycles) | Exceptional durability against foot and wheeled traffic. |

| Hardness | ASTM D2240 (Shore D) | > 80 | Provides a hard, scratch-resistant surface. |

| Chemical Resistance | Immersion per ASTM D1308 | Excellent resistance to water, oils, greases, dilute acids & alkalis. | Protects the floor from common industrial spills and cleaning agents. |

| Slip Resistance (Wet) | DIN 51130 | Can achieve R9-R10 rating with aggregates | Enhances safety in wet or greasy areas like kitchens or food plants. |

| Service Temperature | — | Continuous: -40°F to 180°F (-40°C to 82°C) | Performs in freezer rooms, hot process areas, and outdoor applications. |

Application Areas

The versatility of ResuShield™ XT makes it suitable for a vast range of sectors:

Warehousing & Logistics: Provides a tough, abrasion-resistant surface for high-traffic aisles and loading docks. Ideal for protecting concrete from pallet jack and forklift wear.

Manufacturing & Industrial Plants: Withstands impact, chemical spills, and heavy equipment. Keeps facilities clean and professional.

Food & Beverage Processing: Offers seamless, sanitary, and chemical-resistant flooring that meets USDA and FDA guidelines for easy cleaning and hygiene.

Automotive & Repair Shops: Resists oil, gasoline, brake fluid, and tire marks. Easy to clean and provides a bright, professional-looking workspace.

Commercial & Retail: Decorative flake or quartz systems create attractive, durable floors for showrooms, airports, malls, and big-box stores.

Parking Garages: Protects against chloride de-icing salts, tire abrasion, and UV exposure (with a urethane topcoat), reducing long-term maintenance costs.

Institutional: Durable and easy-to-clean floors for schools, hospitals, laboratories, and municipal buildings.

Professional Installation & Technical Support

Achieving the legendary performance of the ResuShield™ XT system hinges on proper installation. We strongly recommend using our network of approved, professional contractors.

Typical Installation Process:

Surface Preparation (Most Critical Step): Concrete must be mechanically abraded (shot blasted or scarified) to a CSP 3-5 profile to ensure perfect adhesion. All cracks must be repaired, and the slab must be clean, dry, and sound.

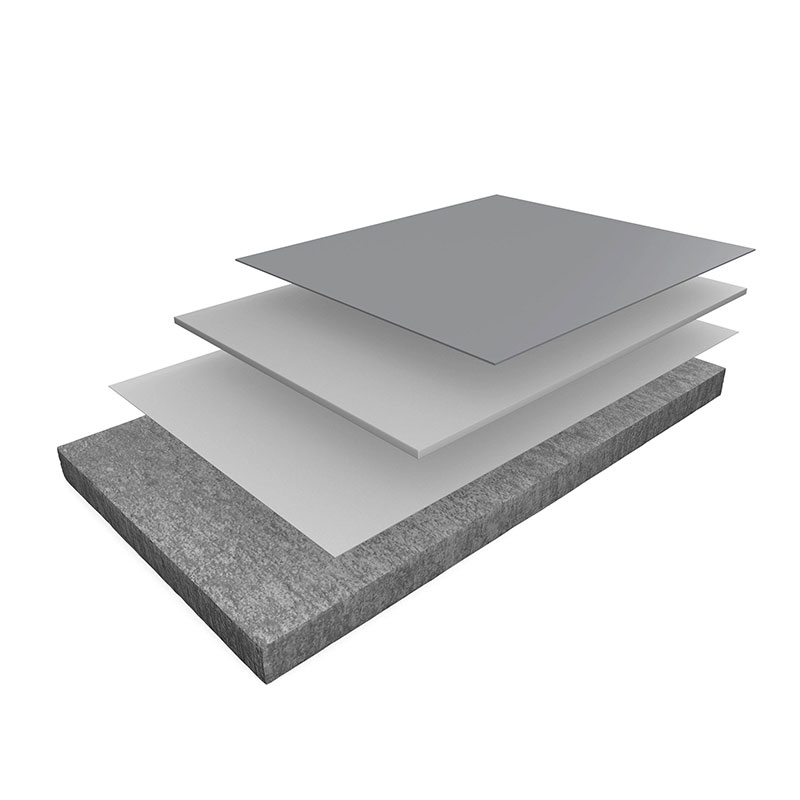

Primer/Sealer Application: A penetrating epoxy primer is applied to seal the concrete and enhance bond strength.

Basecoat/Mortar Layer (Optional): For added thickness, impact resistance, or floor leveling, a filled epoxy mortar coat can be applied and troweled smooth.

Topcoat Application: The ResuShield™ XT Topcoat is applied via roller or squeegee at the specified millage (thickness) for optimal performance and aesthetics.

Curing: The area must be protected during the full cure time, which varies based on temperature and humidity.

Our Support: Our technical service team provides pre-application consultation, detailed specification guides, and on-site support to ensure your project’s success from prep to finish.

Frequently Asked Questions (FAQ)

Q: What is the difference between epoxy and polyurethane flooring?

A: Epoxy systems like ResuShield™ XT are generally harder, offer superior chemical and abrasion resistance, and have higher tensile strength, making them ideal for heavy industrial traffic. Polyurethane coatings are typically more flexible, offer better UV resistance (less yellowing), and have superior thermal shock resistance, making them a better topcoat for outdoor areas or food processing facilities with hot washdowns. Often, a hybrid “epoxy-polyurethane” system is used for the best of both worlds.

Q: How long does it take to install an epoxy flooring system?

A: For a standard 2–3 coat system, installation typically takes 2–4 days for a mid-sized area, depending on complexity, required repairs, and curing conditions between coats. This includes surface preparation, which is the most time-consuming but critical step. Full cure (ability to withstand heavy equipment) is usually achieved within 5–7 days.

Q: How do I maintain my epoxy floor to extend its life?

A: Regular sweeping and occasional damp mopping with a neutral pH cleaner are usually sufficient. For heavier soil, use a recommended cleaner/degreaser. Avoid abrasive pads and harsh acidic cleaners. Place mats at entrances to trap grit. For high-gloss floors, periodic repolishing can restore shine. Immediate cleanup of chemical spills is always recommended.

Q: What is the minimum temperature for applying epoxy flooring?

A: Most epoxy products, including ResuShield™ XT, require a substrate and ambient temperature of at least 50°F (10°C) and rising throughout application and cure. The concrete surface must also be at least 5°F above the dew point to prevent condensation, which can cause adhesion failure.

Q: Can epoxy flooring be installed over existing tile or old paint?

A: It is possible, but not generally recommended without proper assessment and preparation. Existing tile must be fully secure, and the grout lines must be filled. Old paint must be tested for adhesion and may need to be removed. The safest approach is to mechanically prepare the concrete substrate to ensure a direct, strong bond. Consult a professional contractor for an evaluation.

Q: Is epoxy flooring slippery when wet?

A: Standard high-gloss epoxy can be slippery. However, ResuShield™ XT systems can be specified with anti-slip additives (such as silica sand or aluminum oxide) broadcast into the topcoat, or with a textured finish, to achieve higher slip resistance ratings (e.g., R9-R11) suitable for wet areas like commercial kitchens or pool decks.

Q: How much does an epoxy floor cost per square foot?

A: The total cost varies widely based on project size, substrate condition, system design (number of coats, thickness, decorative elements), and geographic location. A basic industrial epoxy system may start in the range of $3–$6 per square foot for materials and professional installation, while more complex systems with multiple coats, heavy flake broadcasts, or special chemical resistance can cost $7–$12+ per square foot. Contact us for a detailed quote based on your specific project.

Q: Can I install epoxy flooring myself as a DIY project?

A: While DIY epoxy kits are available for small residential spaces like garages or basements, industrial and commercial applications require professional installation. Proper surface preparation (often requiring professional grinding equipment), precise mixing, controlled environmental conditions, and experience in application techniques are critical to the system’s long-term performance and warranty. For any business or heavy-traffic facility, we strongly recommend using an approved contractor.

Q: Does epoxy flooring come with a warranty?

A: KAIDA PAINT provides a limited product warranty against manufacturing defects. The performance warranty of the installed system typically depends on proper substrate preparation and installation by a qualified professional. Many of our approved contractors also offer workmanship warranties. Specific warranty details are provided with your project proposal.

Q: How long does epoxy flooring last?

A: In a properly installed and maintained industrial or commercial setting, a high-quality epoxy system like ResuShield™ XT can last 10–20 years or more. Lifespan depends heavily on the severity of traffic, chemical exposure, maintenance practices, and initial installation quality.

Trust & Proven Performance

ResuShield™ XT is not just a product; it’s a proven solution backed by industry trust.

Case Studies: We have successfully installed millions of square feet in automotive plants, distribution centers for major retailers, and food production facilities across the country. These projects showcase our ability to deliver durable, high-performance floors that stand the test of time.

Quality Commitment: Our products are manufactured under strict quality control procedures and are supported by a limited product warranty against manufacturing defects.

Expert Network: We work with a continent-wide network of skilled, approved flooring contractors who are trained in the proper application of our systems.

Your Next Step: Request a Quote or Consultation

Choosing the right flooring system is a significant investment in your facility’s future. You need a partner who provides not just high-quality products, but complete solutions.

For over 15 years, KAIDA PAINT has been at the forefront of advanced coating technology, specializing in durable, high-performance solutions for the most demanding industrial and commercial environments. We understand that your floor is a critical business asset, facing constant challenges from heavy traffic, chemical spills, and rigorous hygiene standards. That’s why we don’t just sell paint; we deliver complete, engineered flooring systems.

Our ResuShield™ XT Topcoat exemplifies this commitment. Developed in-house by our chemists and tested in real-world conditions, it represents the pinnacle of epoxy flooring technology. But our partnership goes beyond the product drum. Our team of technical experts works directly with facility managers, architects, and contractors to analyze your specific needs—whether it’s for a warehouse, food plant, auto shop, or commercial garage. We provide customized system specifications, detailed application guides, and unwavering support throughout the installation process.

Our network of approved applicators ensures your project is executed to the highest standard, guaranteeing the long-term performance and return on investment you expect. When you choose KAIDA PAINT, you choose a single-source partner dedicated to protecting your assets, enhancing your operations, and providing a flooring solution built to last.

Ready to transform your concrete floor? Contact our flooring specialists today for a free project consultation, a detailed specification, or to discuss your specific requirements regarding cost, color options, and installation timelines. Let us help you find the best flooring solution for your industrial, commercial, or residential project.