Description

Product Overview

ResuShield™ Topcoat FX23 is a high-performance epoxy flooring system designed for demanding industrial and commercial environments. It combines a durable epoxy resin with advanced hard aggregate technology to create a seamless, traffic-bearing surface that withstands heavy abuse. This system delivers exceptional abrasion resistance, impact resistance, and chemical tolerance. It provides a waterproof, slip-resistant, and easy-to-clean finish, making it the ideal solution for warehouses, manufacturing plants, food processing areas, and other high-traffic facilities.

User Pain Points & Scenario Analysis

Industrial and commercial floors face relentless challenges that compromise safety, hygiene, and operational efficiency. Common problems include:

Cracking & Damage: Concrete substrates crack, leading to trip hazards and moisture ingress.

Dusting: Unsealed concrete creates constant dust, contaminating products and machinery.

Chemical Attack: Spills of oils, greases, solvents, and cleaning agents degrade standard floors.

Mechanical Wear: Forklift traffic, heavy equipment, and dropped tools cause rapid wear and tear.

Hygiene Issues: Porous surfaces harbor bacteria and are difficult to sanitize, critical in food and pharmaceutical settings.

Slippery Surfaces: Wet or oily conditions create dangerous slip-and-fall risks.

Specific Scenarios:

Food & Beverage Plants: Require floors that are impervious to acidic spills, easy to clean to meet sanitary standards, and provide underfoot safety.

Logistics Warehouses: Need extreme impact and abrasion resistance to handle constant pallet jack and forklift traffic without wearing down.

Automotive Shops: Demand resistance to oil, grease, hydraulic fluids, and tire marks, combined with durability against heavy tools and equipment.

Parking Garages: Require a combination of aesthetic appeal, resistance to de-icing salts, and long-term durability against vehicular traffic.

Product Solution & Key Features

The ResuShield™ Topcoat FX23 system directly addresses these pain points with its engineered properties.

Mechanical Performance:

Abrasion Resistance: Formulated with hard aggregates (like 20-40 mesh silica) for superior wear resistance, outperforming standard industrial paints and coatings.

Impact Resistance: The flexible epoxy system absorbs shocks from dropped objects and heavy loads, preventing cracks and chips.

Crack Bridging: The monolithic membrane can bridge substrate hairline cracks up to 1/16″, preventing reflective cracking.

Chemical & Environmental Tolerance:

Resists a wide range of chemicals including oils, greases, dilute acids, alkalis, and salts.

Provides a waterproof seal that blocks moisture vapor transmission, protecting the concrete slab.

UV-resistant topcoat options are available to prevent yellowing and degradation in sun-exposed areas.

Physical & Safety Characteristics:

Seamless & Non-porous: Eliminates joints where dirt and bacteria accumulate, facilitating easy cleaning and sanitization.

Slip-Resistant: The aggregate broadcast creates a textured, skid-inhibiting surface ideal for wet areas like locker rooms, decks, and ramps.

Hygienic & Easy to Clean: The smooth, non-absorbent finish allows for quick spill removal and effective cleaning with standard industrial cleaners.

Aesthetic & Customization:

Available in a range of standard and custom colors (grays, whites, etc.) to suit facility design and safety coding needs.

Choice of gloss levels from low-sheen to high-gloss finishes.

The system builds a total thickness of 110-120 mils, providing a substantial wearing surface.

Installation & Sustainability:

Designed for professional application by certified contractors.

Meets stringent VOC content limits (<100 g/L for resinous flooring), contributing to better indoor air quality.

Technical Data & Specifications

| Parameter | Specification/Value | Test Standard |

|---|---|---|

| System Type | High-Performance Epoxy Slurry/Broadcast | N/A |

| Total Dry Film Thickness | 110 – 120 mils | ASTM D7091 |

| Abrasion Resistance (Taber) | Excellent (Specific data per product datasheet) | ASTM D4060 |

| Chemical Resistance | Resistant to oils, greases, dilute acids, alkalis | ASTM D1308 / D543 |

| Slip Resistance | Provides skid-inhibiting surface (Aggregate-dependent) | ASTM E303 / DIN 51130 |

| VOC Content | < 100 g/L (Compliant) | EPA Method 24 (40 CFR 59) |

| Compressive Strength | High (Dependent on substrate and system) | ASTM C579 |

| Adhesion to Concrete | Excellent | ASTM D4541 / D7234 |

| Waterproofing | Yes, bridges cracks up to 1/16″ | N/A |

| Typical Service Temperature | -40°F to +180°F (Continuous) | N/A |

Application Areas

The ResuShield™ Topcoat FX23 system is versatile for numerous sectors:

Manufacturing & Industrial Plants

Warehousing & Distribution Centers

Food & Beverage Processing

Pharmaceutical & Laboratory Facilities

Automotive & Aerospace Facilities

Commercial Kitchens & Restaurants

Parking Structures & Ramps

Schools, Hospitals & Institutional Buildings

Installation Process & Technical Support

A successful installation is critical for performance. The key steps involve:

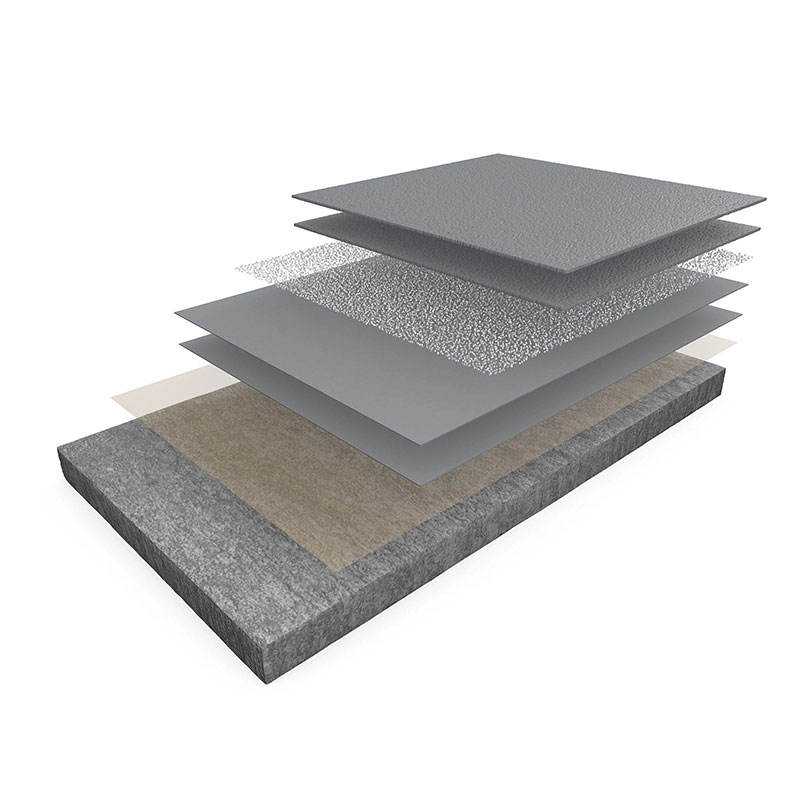

Surface Preparation: Concrete must be abrasive blasted to a CSP 3-5 profile, clean, dry, and structurally sound. Moisture testing (ASTM F1869/F2170) is mandatory.

Priming (Optional): Application of a primer coat to minimize outgassing and enhance adhesion.

Base Coat: Application of the first epoxy coat to seal the substrate.

Wear Course: Application of the epoxy slurry followed by immediate broadcasting of hard aggregate for abrasion and slip resistance.

Grout Coat: Filling the voids between aggregates to create a smooth, solid surface.

Topcoat: Application of the final, chemical-resistant seal coat for protection and easy cleaning.

Curing: The system requires a minimum 24-hour cure before light traffic and several days for full chemical resistance.

Our Commitment: We provide more than just products. We offer comprehensive solutions including pre-installation consultation, specification guidance, and access to a network of trained, certified installers and contractors.

Frequently Asked Questions (FAQ)

Q: How does ResuShield™ Topcoat FX compare to standard epoxy paint?

A: It is a far more robust system, not just a coating. With a thickness over 100 mils and integrated aggregate, it offers significantly higher resistance to abrasion, impact, and chemicals compared to thin-film epoxy paints.

Q: What is the typical cost per square foot for this flooring system?

A: The price varies based on project size, substrate condition, and geographic location. It is an investment in a long-term solution. For an accurate quote, contact us with your project details.

Q: How long does installation take?

A: For a typical warehouse, the process from prep to final cure usually takes 3-5 days, depending on area size and conditions. Proper curing time is essential for performance.

Q: How do I clean and maintain this flooring?

A: Daily dry dust mopping and occasional damp mopping with a neutral cleaner is sufficient. For heavily soiled or skid-resistant surfaces, periodic scrubbing with a brush and rinsing is recommended. Avoid harsh acids.

Q: Can it be applied in a basement or over metal?

A: Yes, it is suitable for basement floors subject to moisture. It can also be applied over properly prepared metal substrates. Consult our technical team for specific substrate guidelines.

Proof & Trust Building

Case Studies: Our systems are installed in Fortune 500 manufacturing facilities, national logistics warehouses, and major food processing companies.

Certifications: Products are formulated to meet or exceed relevant industry standards for performance and environmental compliance.

Expert Network: We work exclusively with professional flooring contractors who carry installer certifications, ensuring quality application.

Partner with KAIDA PAINT

KAIDA PAINT is a leading manufacturer and solution provider specializing in high-performance industrial floor coatings. We don’t just supply paint; we deliver durable, reliable flooring systems backed by deep technical expertise. Our team works directly with facility managers, contractors, and specifiers to design the optimal solution for every challenge, from chemical resistance in a factory to slip safety in a commercial kitchen.

We understand that your business needs a flooring system that lasts, reduces maintenance cost, and keeps your operations running safely. Let us help you prepare, specify, and install the right flooring.

Ready to transform your space? Contact KAIDA PAINT today for a free consultation, technical specification sheets, or to connect with a certified installer in your area.