Description

Product Overview: What is ResuShield™ Deco Flake One?

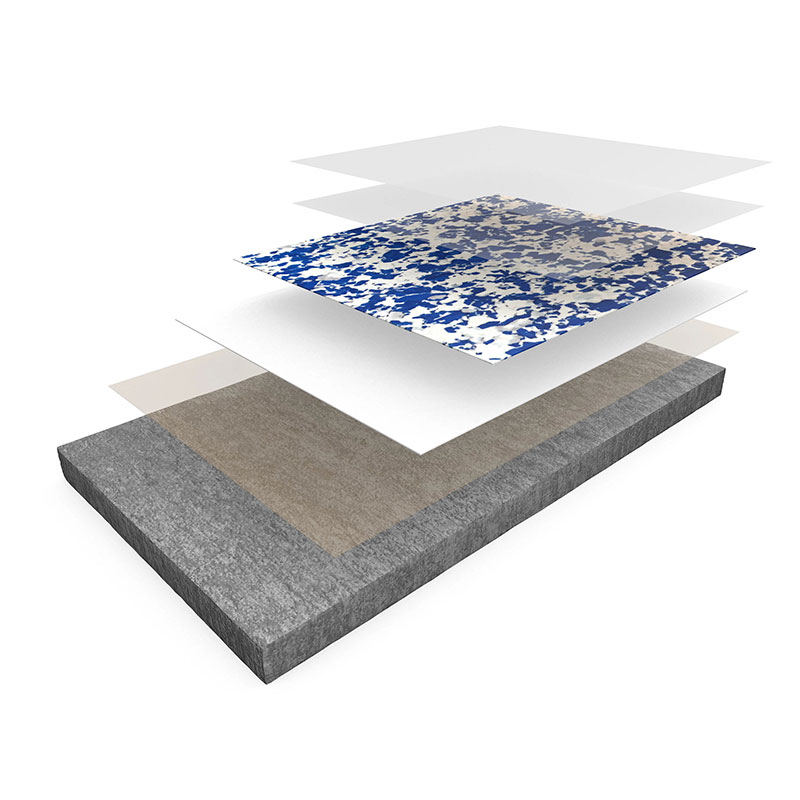

ResuShield™ Deco Flake One is a seamless, decorative, and high-performance resinous flooring system engineered for demanding environments. It combines a durable epoxy basecoat with broadcast colored vinyl flakes, locked in place by a clear, ultra-tough polyurethane grout and topcoat. This system delivers exceptional resistance to chemicals, abrasion, and impact, while its seamless nature prevents dirt and moisture accumulation. It is the ideal solution for pharmaceutical labs, food & beverage plants, warehouses, and other facilities where hygiene, safety, and durability are non-negotiable.

Addressing Critical Industrial Flooring Pain Points

Industrial and commercial floors face relentless challenges. Traditional options like plain concrete or basic paint often fail, leading to:

Degradation & Damage: Constant traffic from heavy machinery and fork lifts causes cracking, pitting, and dusting.

Chemical Attacks: Spills of oils, solvents, acids, and harsh cleaning agents eat away at the floor surface.

Hygiene & Compliance Issues: Porous surfaces harbor bacteria, making clean rooms and food processing areas difficult to sanitize.

Safety Hazards: Slippery or uneven surfaces increase the risk of workplace accidents.

Aesthetic Decline: Dull, stained floors negatively impact the professional image of a company.

The ResuShield™ Deco Flake One system is engineered specifically to solve these problems, offering a long-lasting, professional finish that protects your substrate and your investment.

Core Solutions & Product Features: Why Choose This System?

1. Unmatched Durability & Performance

Mechanical Strength: Offers high abrasion resistance and impact resistance, perfect for warehouse aisles and production areas.

Chemical Shield: Resists a broad spectrum of industrial chemicals, sterilants (like bleach), and cleaning solutions, ensuring longevity in labs and processing plants.

Seamless & Hygienic: The monolithic coating leaves no grout lines or cracks for contaminants to hide, facilitating easy cleaning and meeting strict sanitation standards.

2. Safety & Functionality

Slip-Resistant Options: The textured finish from the broadcast flakes provides inherent slip resistance, enhancing safety even when wet.

Fast Cure & Turnaround: Accelera™ One technology allows for rapid curing, minimizing facility downtime. Foot traffic is often possible within hours.

Thermal & Moisture Tolerance: Performs reliably across a range of temperatures and has excellent adhesion to properly prepared concrete.

3. Aesthetic Flexibility & Customization

Endless Design Possibilities: Choose from a wide array of standard and custom color flake blends to match your corporate identity or zone different areas.

Attractive Finish: The decorative flake system provides a visually appealing, professional look that enhances the work environment.

Multiple Sheens: Available in gloss, satin, or matte finishes to suit your aesthetic and functional needs.

Technical Specifications & Authoritative Data

The following table summarizes key performance data, based on rigorous testing standards, demonstrating the system’s robustness.

| Property | Test Method | Typical Result/Performance |

|---|---|---|

| Abrasion Resistance | ASTM D4060 (CS-17 Wheel) | ≤ 80 mg weight loss |

| Chemical Resistance | ASTM D1308 (24-168 hr exposure) | No change to a wide range of acids, bases, solvents, & disinfectants |

| Adhesion | ASTM D7234 (Pull-off) | > 300 psi (concrete substrate failure) |

| Flexural Strength | ASTM C580 | ~10,000 psi |

| Hardness | ASTM D4366 | 60 (Shore D) |

| Impact Resistance | MIL-DTL-3134J | > 160 in-lbs (Direct), > 80 in-lbs (Reverse) |

| Slip Resistance | Variable (System Dependent) | Provides enhanced traction; can meet specified COF requirements |

Ideal Applications & Industries

The ResuShield™ Deco Flake One system is versatile and trusted across numerous sectors:

Pharmaceutical, Biotech & Life Sciences: Cleanrooms, labs, vivariums, and production areas requiring chemical sterilant resistance.

Food & Beverage Processing: Production floors, packaging areas, and wash-down zones needing USDA/FDA-compliant, easy-to-clean surfaces.

Commercial & Light Industrial: Warehouses, garages, showrooms, retail spaces, and schools seeking a durable, attractive floor.

Institutional Facilities: Hospitals, kitchens, restrooms, and corridors where hygiene and slip resistance are critical.

Professional Installation Process & Support

Achieving the specified performance requires proper installation. Here is a simplified overview of the key steps, which should always be performed by a qualified Installer or contractor:

Surface Preparation (Prep): The concrete substrate must be mechanically abraded (e.g., shot-blasted) to a CSP 1-3 profile to remove contaminants and ensure optimal adhesion. Moisture testing (per ASTM F2170) is critical.

Primer Application: A specialized epoxy primer (Resuprime™ 3579) is applied to seal the substrate and promote bond.

Basecoat & Flake Broadcast: The colored epoxy basecoat (ResuShield™ 2635) is applied, followed immediately by the even broadcast of decorative vinyl flakes.

Grout & Topcoat Sealing: After removing excess flakes, a clear, high-performance polyurethane grout coat (Accelera™ One) is applied to encapsulate the flakes. A final seal coat of Accelera™ One provides a durable, chemical-resistant, and easy-to-clean wear surface.

Curing & Protection: The floor must be protected from traffic and moisture during the full cure period (typically 7 days).

Professional Support is Key: We recommend working with an authorized installer. KAIDA PAINT provides comprehensive technical support, from specification to on-site guidance, ensuring your project’s success.

Frequently Asked Questions (FAQ)

Q: How does ResuShield™ Deco Flake One compare to standard epoxy or tile?

A: It surpasses standard epoxy in chemical and UV resistance due to its polyurethane topcoat. Compared to tile, it is seamless (more hygienic), more impact-resistant, and faster to install with no grout lines to maintain.

Q: What is the typical project turnaround time?

A: The system is designed for a fast turnaround. While dependent on size and conditions, the coating itself can often be applied over a weekend, with light foot traffic possible in hours and full cure in 7 days.

Q: Can this flooring be installed in my existing facility or home basement?

A: Yes, it is an excellent overlay system for existing, sound concrete slabs in both commercial and residential (e.g., basement, garage) settings, provided the slab is properly prepared.

Q: How do I maintain and clean this flooring?

A: Maintenance is simple. Regular sweeping and occasional damp mopping with a neutral cleaner are usually sufficient. Its chemical resistance allows for periodic deep cleaning with stronger disinfectants without damage.

Q: Is it a DIY-friendly kit?

A: Due to the precise mixing ratios, temperature requirements, and need for professional surface prep, this system is not recommended as a DIY project. Professional installation is crucial for warranty and performance.

Trust & Proven Performance

The ResuShield™ Deco Flake One system is backed by the science and global support of a leading manufacturer. Its formulations are tested to international standards (ASTM), ensuring reliable performance. Our company has provided solutions for countless facilities, from global pharmaceutical companies to local warehouses, building a reputation for quality and reliability that contractors and facility managers trust.

KAIDA PAINT Brand Introduction

KAIDA PAINT: Engineering Surfaces for Demanding Environments

For over 15 years, KAIDA PAINT has been at the forefront of advanced coating technologies, specializing in high-performance urethane, epoxy, and polyurethane systems for industrial and commercial applications. We understand that your floor is a critical business asset, facing daily challenges from heavy traffic, chemical spills, and stringent hygiene standards.

Our ResuShield™ Deco Flake One epoxy flooring system exemplifies our commitment to solutions that don’t force you to choose between durability and design. As a leading manufacturer, we control the entire formulation process, ensuring every component from the primer to the polyurethane topcoat works in perfect synergy for maximum performance and longevity.

Our difference lies in our partnership approach. We don’t just sell products; we provide contractors and facility managers with comprehensive technical data, on-site application support, and system specifications tailored to your project’s unique needs. Whether you’re managing a global pharmaceutical facility or a local automotive warehouse, KAIDA PAINT delivers the expertise and reliable flooring solutions you can build on.

Stop compromising on your floor’s performance or appearance.

Contact the KAIDA PAINT team today for a detailed product specification, a site assessment, or to connect with an authorized installer in your country. Let’s build a better foundation for your business.