Description

FortiFlex B is a high-performance, solid-color quartz broadcast flooring system designed for environments where durability, hygiene, and minimal downtime are critical. Combining a 100%-solids epoxy formulation with flintshot quartz broadcasts, this system delivers a textured, slip-resistant surface that stands up to heavy foot traffic, chemical spills, and UV exposure. With a nominal thickness of 1/8″ and a cure time as fast as 2 hours per coat, FortiFlex B is the go-to solution for facilities operating 24/7.

Key Features & Benefits

- Rapid Cure Technology

Achieve foot traffic readiness in 2.5–5 hours (depending on temperature).

Full service restored within 24 hours—minimize operational disruption.

- Exceptional Durability

Compressive strength: 12,500 psi (ASTM C-379).

Tensile strength: 4,000 psi (ASTM D-638).

Resists abrasion, impact, and heavy loads—ideal for industrial and commercial settings.

- Superior Chemical & UV Resistance

Withstands common chemicals, sanitizers, and oils.

UV-stable topcoat prevents yellowing and fading—perfect for showrooms and laboratories.

- Slip-Resistant & Safe

Textured quartz finish provides traction, even when wet.

Meets ANSI standards for static (>0.6) and dynamic (>0.42) coefficient of friction.

- Seamless & Hygienic

Non-porous surface inhibits microbial growth—easy to clean and maintain.

Ideal for cleanrooms, pharmaceutical facilities, and food processing areas.

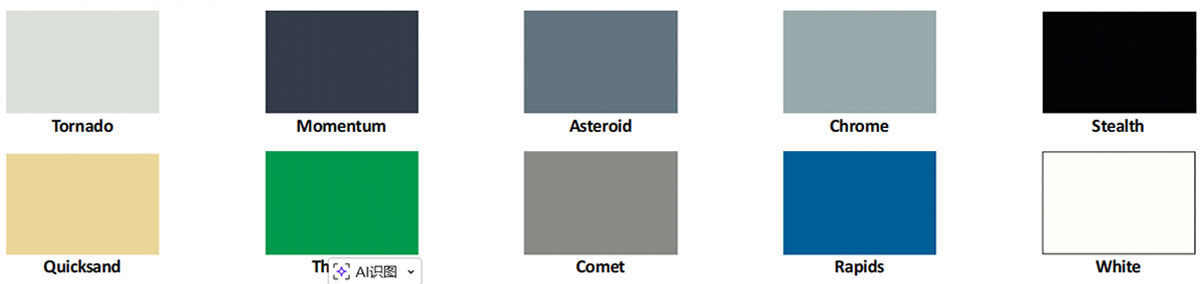

- Customizable Aesthetics

Available in standard and custom colors (e.g., Tornado, White, Stealth).

Use our Flooring Visualizer Tool to preview colors in your space.

Technical Specifications

| Property | Value |

|---|---|

| Total System Thickness | 1/8″ |

| Weight Solids | 96% |

| VOC Content | 33 g/L |

| Service Temperature | Up to 200°F |

| Taber Abrasion Resistance (ASTM D-4060) | 25 mg |

| Pot Life @ 70°F | 10–15 min |

| Full Chemical Resistance | 7 days |

| Flame Spread Index (ASTM E-84) | Class B |

System Components

Primer – Ensures superior adhesion to concrete substrates.

Base Coat/Broadcast – Pigmented resin with first quartz broadcast.

Second Broadcast – Enhances texture and color consistency.

Grout/Seal Coat – Provides a seamless, chemical-resistant finish.

Ideal Applications

Cleanrooms & Laboratories

Pharmaceutical & Healthcare Facilities

Schools & Universities

Supermarkets & Cafeterias

Showrooms & Retail Spaces

Restrooms & Locker Rooms

Why Choose FortiFlex B?

Unlike traditional epoxy flake systems or vinyl chip flooring, FortiFlex B uses a solid color quartz broadcast for unmatched durability and a consistent, low-maintenance finish. Its rapid cure time outperforms conventional polyaspartic floor coatings, making it the smart choice for time-sensitive projects.

Frequently Asked Questions

Q: How does FortiFlex B compare to epoxy flake flooring?

A: While both systems use broadcasts, FortiFlex B incorporates flintshot quartz for enhanced wear resistance and a uniform solid color—unlike decorative flakes.

Q: Can I use FortiFlex B in wet areas?

A: Yes! The textured finish and chemical-resistant topcoat make it suitable for restrooms, locker rooms, and food service areas.

Q: Is this system DIY-friendly?

A: Due to its fast pot life and professional application requirements, we recommend installation by certified contractors.

Trusted by Industry Leaders

Backed by KAIDA PAINT’ global expertise in high-performance flooring, FortiFlex B is backed by:

Technical support & specification services.

Custom color matching & design visualization tools.

Regional commercial teams for localized support.

Call to Action

Ready to Transform Your Space?

📞 Contact a KAIDA PAINT flooring expert today for a quote or sample.