Urethane Concrete Mortar Flooring System

Urethane Concrete Mortar Flooring System

Polyurethane mortar flooring system is an innovative ground system specifically developed to address the hygiene, heavy traffic resistance, moisture tolerance, and corrosion resistance requirements of the food industry. Unlike traditional epoxy flooring, urethane mortar flooring can withstand repeated steam or boiling water cleaning, whereas epoxy resin systems are unsuitable for high-temperature cleaning and are typically limited to dry environments. In many food factories where epoxy mortar systems have been installed, substantial evidence shows that epoxy surface coatings fail to meet the extreme demands of the food industry.

The urethane mortar flooring system offers a degree of flexibility, providing excellent crack bridging, superior impact resistance, enhanced mechanical wear resistance, UV stability, and chemical corrosion resistance—particularly against organic acids and high-temperature steam cleaning.

Combining the advantages of epoxy flooring and sheet materials while overcoming their limitations, polyurethane cement mortar flooring can be applied in food processing plants, beverage factories, slaughterhouses, pharmaceutical plants, fine chemical plants, public corridors, schools, offices, exhibition halls, parking lots, and art centers—any industrial or commercial setting with special requirements. These unique properties cannot be replicated by any other technology.

Problems with Tradition Epoxy Flooring Systems

- Lack of long-term chemical resistance – Prone to corrosion

- Inability to withstand cleaning liquids above 60°C – Poor heat resistance

- Unsuitable for steam or hot chemical sterilization – Incompatible with high-temperature media

- Vulnerable to thermal shock – Cracking and delamination under rapid temperature changes

- Cracking, peeling, and delamination under impact – Low impact resistance

- Multiple joints trap dirt and bacteria – Difficult to sanitize

- Susceptible to thermal cycling and mechanical wear – Poor abrasion resistance

- Hard to remove grease and contaminants – Health hazards due to poor cleanability

- Solvent-based systems risk soil contamination – Permeability issues

- Vulnerable to subfloor moisture – Poor waterproofing

- Long renovation periods – Extended downtime before reuse

- Failure at -20°C to -40°C – Peeling, delamination, and cracking in extreme cold

- Short service life – Poor long-term durability

Polyurethane mortar flooring overcomes all these limitations, making it the optimal choice for demanding industrial and commercial environments.

Advantages of Urethane Mortar Flooring

The urethane mortar flooring system represents the highest-performance polyurethane flooring solution, offering unique advantages including: exceptional temperature resistance (withstanding up to 115°C at 9mm thickness and as low as -40°C), outstanding chemical resistance to oils, acids, alkalis and other corrosive substances, superior mechanical load-bearing capacity with heavy-duty wear and impact resistance, slip-resistant properties, easy cleaning and steam-cleaning capability, impermeability to water, oil and other liquids, solvent-free (VOC-free) material composition, compliance with EN 1186 standards for contamination resistance, an antibacterial seamless surface that inhibits microbial growth, and long-term durability. This comprehensive combination of properties makes it the premier choice for demanding industrial and commercial applications.

Certifications

HACCP, FDA, CE, USDA, international food-grade certified.

Wear-resistant

Excellent abrasion and impact resistance compared to epoxy floors.

Anti-corrosion

Superior comprehensive anti-corrosion performance.

Temperature Resistance

Withstands short term thermal shock from -30℃ to 150℃

Water Resistance

Can wash 5Mpa water for steam purging, clening and sterilization.

Anti-Slip

Features a heavy anti-slip texture, meeting the antislip requirements in extreme environments.

Urethane Mortar Floor Case

Urethane Mortar Self-Leveling Flooring Construction Process

Step 1: Substrate Inspection and Preparation

The concrete substrate must be structurally sound, densely compacted, and uniformly level, with all strength properties rigorously tested to meet design specifications. The minimum requirement is C30-grade concrete, achieving a compressive strength exceeding 30 MPa after 28 days of curing. The surface must exhibit no defects such as dusting (loose particles), hollow spots (voids or delamination), or pitting (surface irregularities). Additionally, the concrete’s tensile strength must surpass 2 MPa to ensure proper adhesion of subsequent layers. Strict compliance with these parameters is essential for optimal performance of the polyurethane mortar self-leveling system.

The moisture content of the concrete substrate must be less than 8%.

The concrete substrate must achieve a minimum strength grade of C30.

The substrate must achieve a minimum pull-off adhesion strength of 2 MPa.

The substrate must exhibit excellent flatness with no water ponding.

Step 2: Shot Blasting (Mechanical Surface Preparation)

Concrete Surface Preparation by Shot Blasting

Grinding vs ShotBlasting Process Comparison

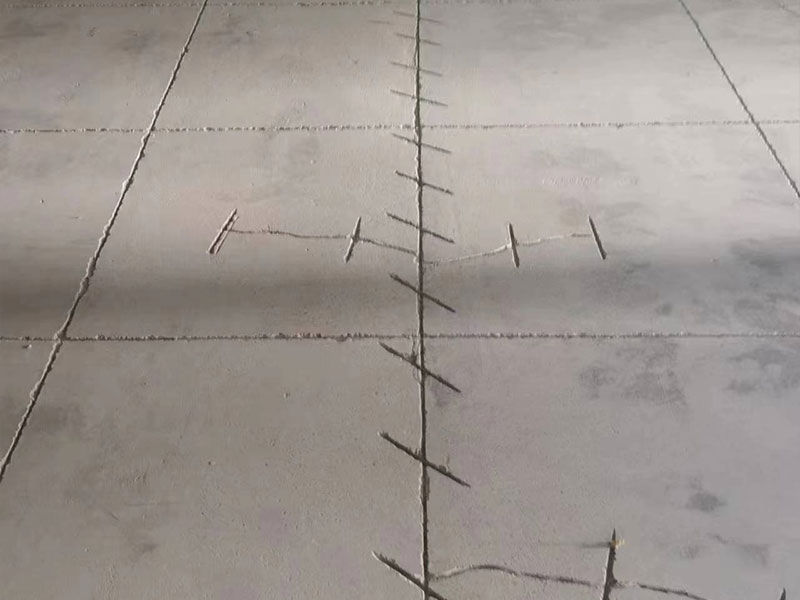

Step 2: Substrate Preparation (Anchor Groove Cutting)

Dry cutting of anchor grooves with a concrete saw

The anchor groove cutting depth should generally be 1.5 to 2 times the thickness of the coating/overlay material.

Step 2: Substrate Preparation (Edge Treatment)

Corner Anchor Groove Cutting

Edge Grinding Treatment

Step 2: Substrate Preparation (Detail Treatment)

Doorway Anchor Groove Cutting

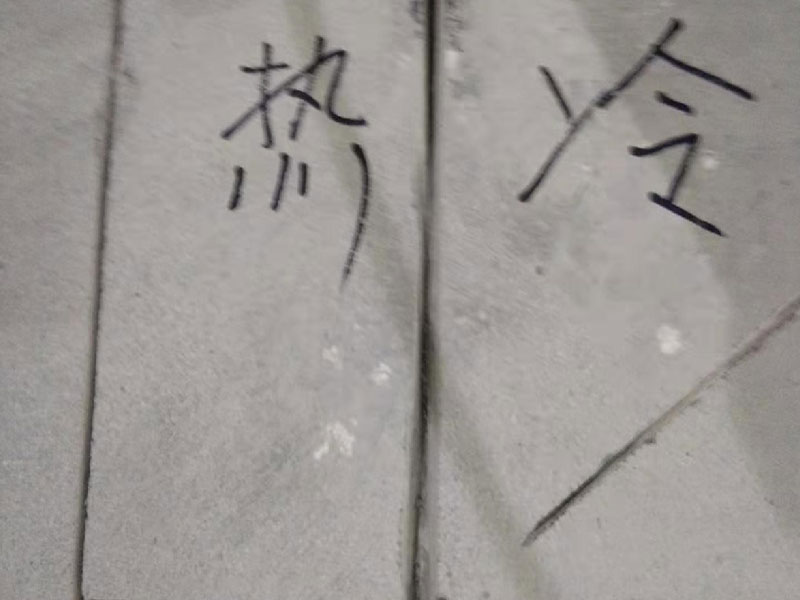

Anchor Groove Cutting at Thermal Transition Zones

Step 3: Application of Polyurethane Mortar Base Layer (Trowel-On)

The primer shall be applied by troweling. Normally one coat is sufficient, while two coats are required for poor substrate conditions. Simultaneously, water-based polyurethane mortar shall be used to fill surface voids, creating mechanical anchors.

Step 4: Polyurethane Mortar Topcoat Application (Self-Leveling)

The primer shall be applied by troweling. Normally one coat is sufficient, while two coats are required for poor substrate conditions. Simultaneously, water-based polyurethane mortar shall be used to fill surface voids, creating mechanical anchors.

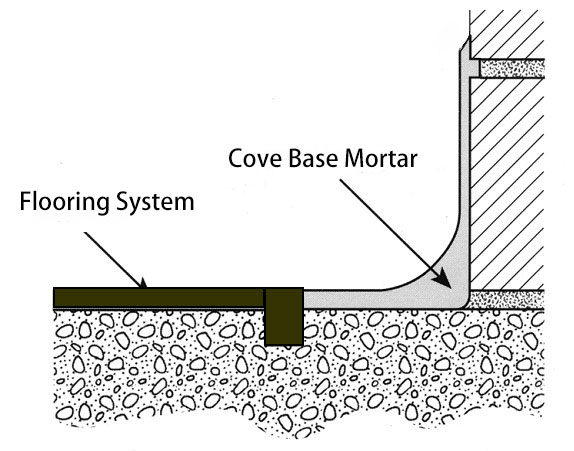

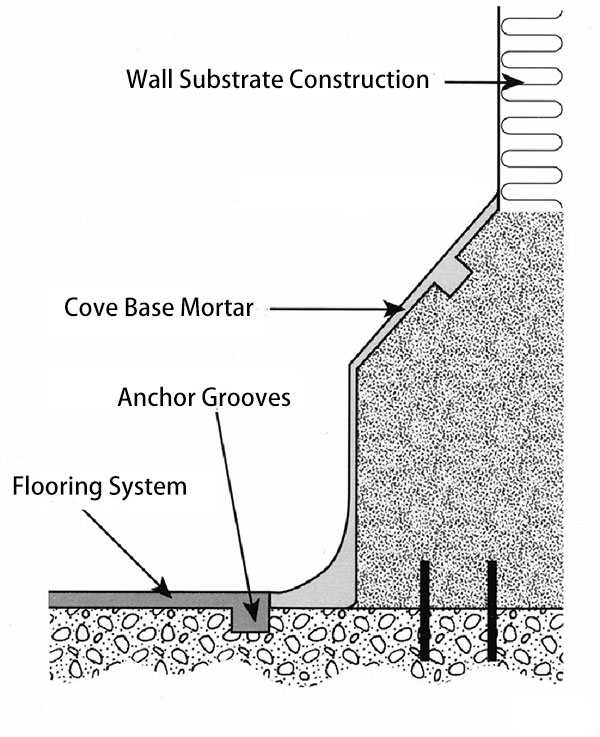

Radius Edge Construction

Mix into dry mortar for base application

Shape with radius trowel

After curing, grind for topcoat application

Detail Treatment

Radius Cove Base

Plinth/Kerb Wall Solution

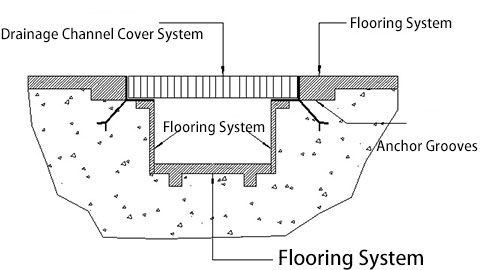

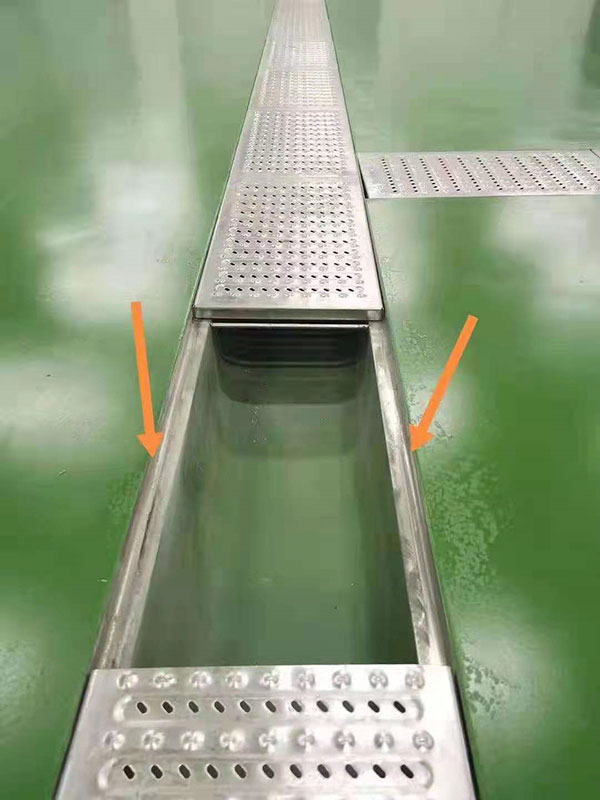

Drain Channel/Gully Solution

Finished Effect (Self-Leveling Surface)

KAIDA PAINT JINYU® Urethane System Products

-

JINYU® MF 4-6mm Polyurethane Paint For Concrete Floors

Read more -

JINYU® UD 9-12mm Heavy-Duty Anti-Slip Polyurethane Concrete Floor Paint

Read more -

JINYU® HD Heavy-Duty Urethane Floor Coating

Read more -

JINYU® SL Self-Leveling Urethane Floor Coating Semi-Gloss Finish

Read more -

JINYU® DT Abrasion-Resistant PU Topcoat

Read more -

JINYU PAINT® MF Self-leveling PU Screed Flooring System

Read more -

PU3600 Polyurethane Ultra Abrasion Resistant Finish

Read more -

Anti-slip Self-leveling Anticorrosive Load-bearing Polyurethane Concrete Floor Paint

Read more -

Self-leveling Heavy-duty Anticorrosive Polyurethane Concrete Floor Coating

Read more -

WPU100 High Gloss Clear Water-based Polyurethane Finishs

Read more -

WPU100 Water-based Polyurethane Floor Finish

Read more

REQUEST A CALLBACK

For bespoke industry flooring solutions talk to KAIDA® JINYU PAINT® today.

We offer free no obligation advice and can provide a price range on the first contact.

- +86-158-229-255-23(whatsapp)

- kaida@jinyupaint.com

FAQ

- The Ultimate Seafood Processing Flooring Solution丨KAIDA JINYU® Delivers High-Performance Floors

- Old Plant Renewal: Flooring Safety Upgrade in a Red Sausage Production Workshop

- The Ultimate Urethane Mortar Floor Solution for High-Traffic Cold Storage Flooring

- Case Study: Why Top Chili Plants Choose Polyurethane Mortar Floors by KAIDA

- Why Polyurethane Mortar Flooring is the Best Choice for Prepared Food Factories

Contact Us

Contact: Ms. Sabella Wei

Phone: 86-022-83859963

Whatsapp: 15822925523