Description

Product Overview

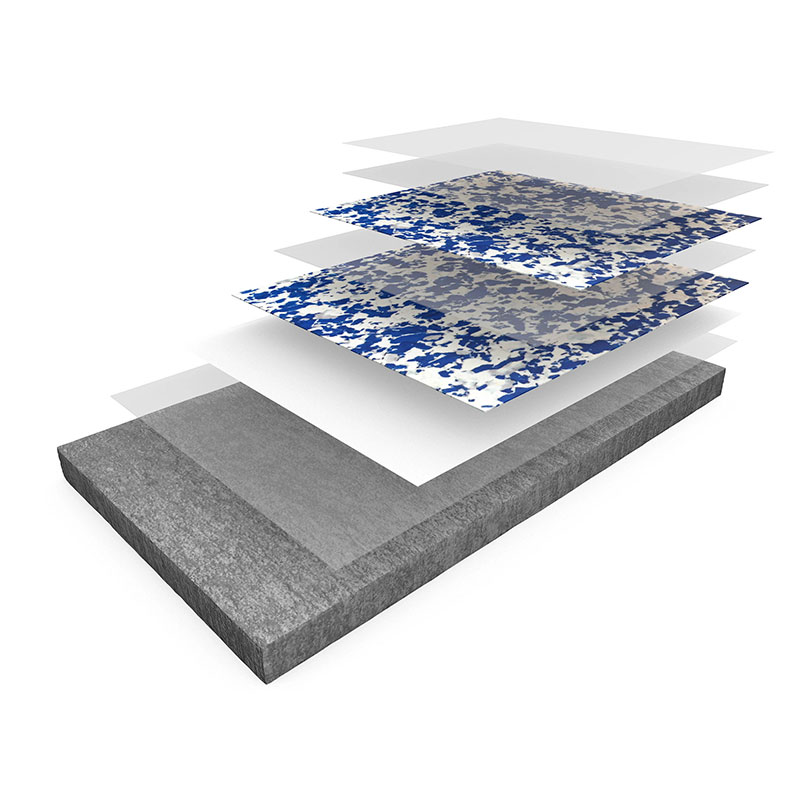

ResuShield™ Deco Flake DB is a high-performance, decorative epoxy flooring system designed for demanding industrial, commercial, and institutional environments. This multi-layer system incorporates a vibrant blend of decorative vinyl chips broadcast into a durable, high-solids epoxy resin, sealed with a UV-resistant grout coat, and finished with a clear, light-stable polyurethane topcoat. It delivers exceptional abrasion resistance, formidable chemical protection, and a seamless, sanitary surface. Engineered for long-term performance, the ResuShield Deco Flake DB system provides a robust and aesthetically customizable flooring solution for facilities where durability, safety, and appearance are critical.

User Pain Points & Scenario Analysis

Industrial and commercial flooring faces constant challenges that can compromise safety, cleanliness, and operational efficiency. Common issues include:

Deterioration & Dusting: Untreated concrete floors generate dust, contaminating products and air quality, especially in clean rooms, pharmaceutical operations, and food processing plants.

Chemical Damage: Spills from oils, solvents, acids, and alkalis in warehouses, automotive shops, and laboratories can degrade standard floors, leading to costly repairs.

Mechanical Wear & Impact: Heavy traffic, forklifts, and dropped tools in industrial settings and logistics centers cause cracking, chipping, and rapid wear.

Hygiene & Sanitation: Porous surfaces harbor bacteria and are difficult to cleaning, posing risks in healthcare, schools, and restaurants.

Aesthetic & Functional Downtime: Outdated or failing floors present a poor image for businesses like retail stores and office buildings, and installation/repair downtime disrupts operations.

The ResuShield Deco Flake DB system is engineered specifically to address these pain points, offering a long-lasting, low-maintenance coating that protects your substrate and enhances your space.

Product Solution & Key Features

1. Superior Durability & Mechanical Performance

Abrasion Resistance: Withstands heavy foot and wheeled traffic. Independent testing shows excellent results under ASTM D4060 (Taber Abraser).

Impact & Crack Resistance: The epoxy resin system offers high tensile and compressive strength, bridging minor subfloor cracks and resisting damage from impacts.

Seamless & Sanitary: A monolithic surface eliminates grout lines and joints where dirt and moisture accumulate, facilitating easier cleaning and meeting high hygiene standards.

2. Exceptional Chemical Resistance

Formulated to resist a broad spectrum of chemicals, including oils, greases, dilute acids, alkalis, and many solvents, making it ideal for pharmaceutical, biotech, automotive, and food processing facilities.

3. Customizable Aesthetics & Safety

Limitless Design: Choose from unlimited standard and custom color blends of decorative flakes to create unique patterns, marble effects, or corporate branding.

Finish Options: Available in high-gloss or satin finish to suit the desired look and light reflection needs.

Enhanced Safety: Can be formulated to meet required slip resistance ratings for added safety in kitchens, bathrooms, and pool deck areas.

4. Professional-Grade Application System

Proven Layering: The system includes optional primer, basecoat(s), double flake broadcast, grout coat, and protective topcoat for maximum performance.

Technical Support: Comes with detailed installation guidelines for professional contractors, ensuring proper prep and application.

Technical Specifications & Data

The following table outlines the typical physical properties of the cured ResuShield™ Deco Flake DB system, based on independent laboratory testing and standardized methods.

| Property | Test Method | Typical Result / Value |

|---|---|---|

| Abrasion Resistance | ASTM D4060 (CS-17 Wheel, 1000g load, 1000 cycles) | 18 mg loss |

| Adhesion to Concrete | ASTM D4541 | 450 psi (Concrete Failure) |

| Shore D Hardness | ASTM D635 | 80-85 @ 0 sec; 75-80 @ 15 sec |

| Compressive Strength | ASTM D635 | 13,500 psi |

| Tensile Strength | ASTM D2370 | 8,000 psi |

| Elongation (Resin) | ASTM D2370 | 6% |

| Flammability | ASTM D635 | 182 mm/min |

Application Areas

The versatility of the ResuShield Deco Flake DB makes it the best choice for numerous sectors:

Healthcare & Laboratories: Hospitals, clinics, clean rooms. Demands seamless, chemical-resistant, and easily sanitized surfaces.

Commercial & Retail: Office buildings, shopping malls, showrooms. Benefits from aesthetic appeal, durability, and low maintenance.

Education & Hospitality: Schools, universities, stadiums, restaurants. Requires easy cleaning, stain resistance, and a welcoming appearance.

Industrial & Manufacturing: Warehouses, pharmaceutical plants, food & beverage facilities. Needs heavy-duty protection against chemicals, abrasion, and impact.

Automotive & Aviation: Garages, hangars, maintenance bays. Resists fuels, oils, and heavy equipment traffic.

Installation Process & Support

A successful installation by approved contractors is crucial for performance. Key stages include:

Surface Preparation (Prep): Concrete must be abrasive blasted to a CSP 2-3 profile to ensure proper adhesion. All contaminants must be removed.

Primer Application (Optional): A primer coat may be applied to porous concrete to minimize outgassing.

Base Coat & Flake Broadcast: The first epoxy basecoat is applied, followed immediately by a broadcast of decorative vinyl flakes. This is repeated for a second layer for full, rich coverage.

Grout Coat: A UV-resistant epoxy coat is applied to fill voids between flakes and create a smooth, sealed surface.

Topcoat Application: A final clear polyurethane or urethane topcoat (e.g., ResuShield UVE or HTS 100) is applied for enhanced chemical resistance, UV stability, and desired finish (satin/gloss).

Curing: The system requires adequate curing time (typically 24 hours for light traffic) at recommended temperatures (50-90°F substrate) to develop full properties.

Our Commitment: We provide comprehensive technical data sheets, application guides, and access to expert support to ensure your contractor achieves a flawless, long-lasting flooring installation.

Frequently Asked Questions (FAQ)

Q: What is the difference between a standard epoxy floor and the Deco Flake DB system?

A: While both use epoxy resin, the Deco Flake DB system incorporates multiple layers and a double broadcast of decorative vinyl flakes. This creates a much thicker, more durable, and highly decorative finish with superior impact resistance and a unique aesthetic compared to a standard thin epoxy coating.

Q: How long does the installation process take?

A: Project timelines vary based on size, substrate condition, and environmental factors. Generally, after prep, the coating application over a typical area can span 3-5 days, including time between coats and final cure before full operational use.

Q: How do I maintain a ResuShield Deco Flake DB floor?

A: Maintenance is simple. Regular sweeping and damp mopping with neutral pH cleaners are usually sufficient. Avoid harsh abrasive cleaners or steel wool. The seamless, non-porous surface makes cleaning quick and effective.

Q: Can this system be applied in cold temperatures?

A: The substrate and ambient temperature should ideally be between 50°F and 90°F during application. Specific products have defined working times at different temperatures. Consult the technical data sheet for details.

Trust & Proven Performance

ResuShield™ systems are specified by facility managers, engineers, and contractors worldwide for critical environments. Our formulations are backed by rigorous testing against international standards (ASTM). We partner with a global network of certified installers to deliver consistent, high-quality results.

Your Next Step: Request a Consultation

Choosing the right flooring system is a significant investment. Let our experts help you determine if the ResuShield Deco Flake DB is the optimal solution for your specific needs regarding chemical resistance, traffic, design, and budget.

Contact us today for:

A detailed product sample and color chart (pictures online).

A project-specific quotation (cost per square foot).

A referral to a qualified contractor in your city or country.

Technical support for your installation team.

KAIDA PAINT: Your Partner in High-Performance Flooring Solutions

At KAIDA PAINT, we are more than just a manufacturer; we are your dedicated partner in protecting and enhancing industrial and commercial assets. With expertise in advanced polyurethane, epoxy, and urethane technologies, we develop flooring solutions that stand up to the most demanding environments from chemical plants and food processing facilities to modern warehouses and prestigious commercial spaces.

Our ResuShield™ line, including the Deco Flake DB system, embodies our commitment to quality, innovation, and support. We provide not only premium products but also unparalleled technical guidance, installation best practices support, and a reliable supply chain. Whether you’re a facility owner, a project contractor, or a design professional, choose KAIDA PAINT for a flooring system that delivers lasting performance, safety, and beauty.

Ready to transform your floor? Get in touch with our team for a custom quote and specification support.