JINYU PAINT® Golvbeläggning av polyuretan

JINYU PAINT® GOLVPRODUKTER AV POLYURETAN

Visar 1–16 av 21 resultat

-

Anti-slip Självutjämnande Antikorrosiv Bärande Polyuretan Betong Golv Färg

Läs mer på engelska -

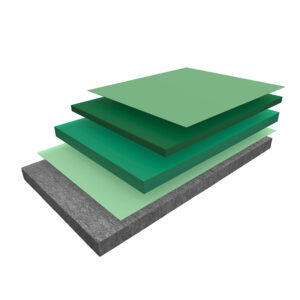

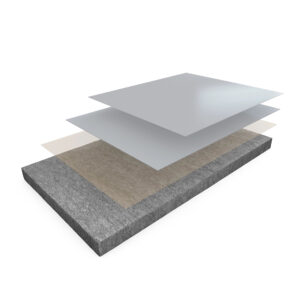

FlexTop™ Comfort SL Urethane Flooring System

Läs mer på engelska -

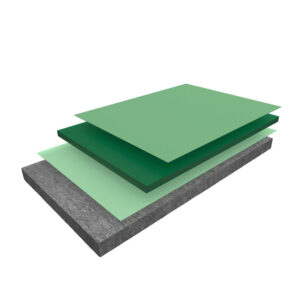

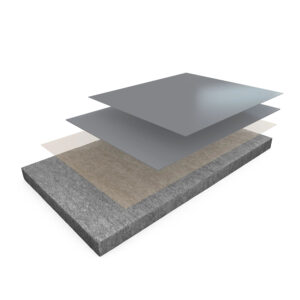

FlexTop™ RXC Urethane Flooring System

Läs mer på engelska -

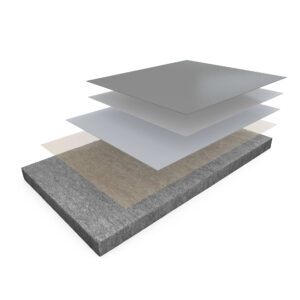

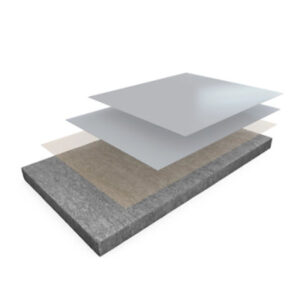

FlexTop™ SL Urethane Flooring System

Läs mer på engelska -

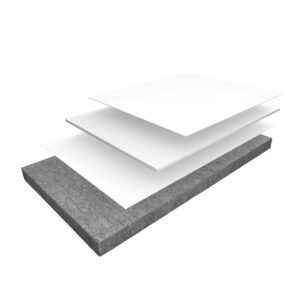

JINYU PAINT® MF Självnivellerande PU-golvbeläggningssystem

Läs mer på engelska -

JINYU® DT nötningsbeständigt toppskikt av PU

Läs mer på engelska -

JINYU® HD Heavy-Duty golvbeläggning av uretan

Läs mer på engelska -

JINYU® MF 4-6 mm polyuretanfärg för betonggolv

Läs mer på engelska -

JINYU® SL Självutjämnande golvbeläggning av uretan Halvblank yta

Läs mer på engelska -

JINYU® UD 9-12mm Kraftig halkskyddande polyuretanfärg för betonggolv

Läs mer på engelska -

Polypro™ Advanced NMP Performance EV Urethane Golvbeläggningssystem

Läs mer på engelska -

Polypro™ NMP Performance EV golvbeläggningssystem av uretan

Läs mer på engelska -

Polypro™ Performance HPS Uretan-golvbeläggningssystem

Läs mer på engelska -

Polypro™ Performance HTS golvbeläggningssystem av uretan

Läs mer på engelska -

Polypro™ XT Topcoat AC Uretan Golvbeläggningssystem

Läs mer på engelska -

Polypro™ XT Topcoat TX Uretan Golvbeläggningssystem

Läs mer på engelska

Fördelar med golvbeläggningar av polyuretan (Pu Flooring)

Golvbeläggningar av polyuretan (uretan) är en högpresterande golvlösning som används i stor utsträckning inom industri, handel och bostäder tack vare sin överlägsna hållbarhet, flexibilitet och estetiska tilltal.

1. Exceptionell slitstyrka

- Hög vidhäftning till olika underlag (betong, epoxi, kakel etc.)

- Mekaniskt robust-tålig mot nötning, stötar och tunga belastningar

- Testad prestanda: Tål 500 g stålkulor från 100 cm utan att spricka eller flagna

- Kemisk beständighet och korrosionsbeständighet-idealisk för fabriker, lager och kemiska anläggningar

2. Utmärkt anpassningsbarhet (mångsidighet)

- Brett färgurval-anpassningsbar för att matcha varumärkes- eller designbehov

- Justerbar tjocklek (tunna dekorativa skikt eller tjocka lager av industriell kvalitet)

- Funktionella alternativ: Antistatisk, halkskyddande, flamskyddande, ledande etc.

3. Andningsförmåga (fuktkontroll)

- Vattenbaserade PU-beläggningar tillåter ånggenomgång-förhindrar bubblor och delaminering

- Blockerar yttre fukt-ideal för fuktiga miljöer (livsmedelsfabriker, källare, pooler)

4. Snabb och enkel installation

- Vattenförtunnande-Enkel applicering och rengöring

- Snabb härdning: Gångbar inom 24 timmar, fullt lastbärande inom 7 dagar

- Låg VOC och miljövänlig-uppfyller standarder för grönt byggande

5. Estetisk och sömlös finish

- Alternativ för glansigt/matt/halvblankt-förbättrar det visuella intrycket

- Sömlös och icke-porös-förhindrar ansamling av damm (perfekt för sjukhus och laboratorier)

- UV-beständiga färger-Ingen blekning över tid

6. Enkelt underhåll och reparation<

- Slät yta-lätt att rengöra (vatten och milda rengöringsmedel)

- Reparerbar-lokaliserade reparationer utan fullständig omlackering

- Fläck- och kemikaliebeständig-minskar de långsiktiga kostnaderna

7. Lång livslängd och extrem hållbarhet

- 20+ års livslängd-överträffar epoxi och traditionell betong

- Tål -60°C till 120°C-perfekt för frysar, livsmedelsanläggningar och utomhusbruk

- Förstärker betonggolv-förhindrar sprickbildning och damm

Golv av polyuretan Industriell tillämpning

Epoxi eller polyuretan?

Polyuretangolv är ett överlägset alternativ till epoxi i många krävande industriella miljöer och erbjuder ökad flexibilitet, bättre UV-stabilitet och bättre motståndskraft mot termisk chock och nötning. Epoxibeläggningar ger utmärkt vidhäftning och kemikaliebeständighet, men polyuretan är överlägset i miljöer som kräver större elasticitet och väderbeständighet. Viktiga applikationsscenarier inkluderar:

- Lager och logistikcenter

Till skillnad från epoxi bibehåller polyuretan sin flexibilitet vid kraftiga stötar, vilket förhindrar sprickbildning och flisning vid kontinuerlig gaffeltruckstrafik. Dess överlägsna nötningsbeständighet garanterar längre livslängd i högtrafikerade områden. - Anläggningar för livsmedels- och dryckesförädling

Polyuretan ger bättre motståndskraft mot termisk chock än epoxi vid frekventa varma spolningar, vilket förhindrar blåsbildning eller avskalning. Det ger också högre halkskydd i våta förhållanden. - Läkemedels- och renrumsanläggningar

Båda ger sömlösa ytor, men polyuretan har bättre motståndskraft mot upprepad kemisk exponering och behåller sitt utseende utan att gulna eller försämras i UV-steriliseringsljus. - Fordons- och flygindustrianläggningar

Jämfört med epoxi uppvisar polyuretan högre motståndskraft mot jetbränsle, hydraulvätskor och extrema temperaturer utan att mjukna eller bli spröd. - Tillverknings- och monteringsanläggningar

Polyuretangolv överträffar epoxigolv i miljöer med stora temperaturvariationer tack vare sin överlägsna förmåga till termisk cykling och minskade känslighet för fukt under installationen. - Kyl- och frysrum

Till skillnad från epoxi, som kan bli sprött och spricka i minusgrader, behåller polyuretan sin flexibilitet och slagtålighet, vilket garanterar hållbarhet i frysande miljöer.Polyuretangolv kombinerar avancerad mekanisk styrka med kemisk och miljömässig beständighet, vilket gör det till ett mer hållbart och anpassningsbart val än epoxi för moderna industrianläggningar med dynamiska driftsförhållanden.

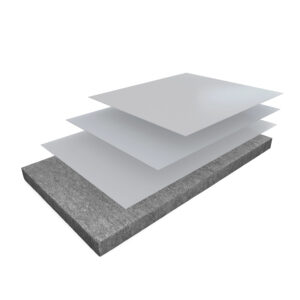

Vanliga typer av golvbeläggningar av polyuretan (PU)

Golvbeläggningar av polyuretan är mycket mångsidiga och kan anpassas för olika tillämpningar. Nedan följer de vanligaste klassificeringarna, tillsammans med deras viktigaste funktioner och användningsområden

① Glansig/matt vattenbaserad golvbeläggning av polyuretan

- Typer: Högblank, matt, halvmatt finish

- Tillämpningar: Industrigolv, sjukhus, tunnelbanevagnar, bibliotek och kommersiella utrymmen

- Fördelar: Eliminerar behovet av vaxning/polering och bibehåller en långvarig glans

② Ultra slitstark golvbeläggning av polyuretan

- Funktioner: Hög densitet, extrem hårdhet, rep- och nötningsbeständighet

- Tillämpningar: Maskinverkstäder, parkeringsgarage, idrottsplatser, lagerlokaler

- Fördelar: Tål tunga maskiner, gaffeltruckar och mycket fottrafik

③ Snabbtorkande golvbeläggning av polyuretan

- Typer: Snabb härdning vid låg temperatur, snabb härdning vid rumstemperatur

- Tillämpningar: Vinterkonstruktion, snabba reparationer, linjemarkering

- Fördelar: Minskar stilleståndstiden, perfekt för tidskänsliga projekt

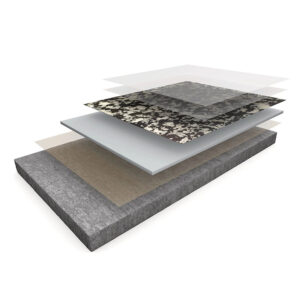

④ Dekorativ golvbeläggning av polyuretan

- Funktioner: Levande färger, dekorativa flingor/kvartsalternativ, hög estetik

- Tillämpningar: Sjukhus, skolor, köpcentra, kontor

- Fördelar: Kombinerar skönhet och hållbarhet, lätt att rengöra

⑤ Hög-/lågtemperaturbeständig PU-golvbeläggning

- Prestanda: Stabilt från -40°C till 120°C

- Tillämpningar: Anläggningar för livsmedelsbearbetning, kylförvaring, frysar

- Fördelar: Ingen sprickbildning i extrema temperaturer, FDA-kompatibel

⑥ Golv av polyuretan för sport- och lekplatser

- Funktioner: Utmärkt stötdämpning, bullerdämpning, elasticitet

- Tillämpningar: Tennisbanor, löparbanor, gymgolv

- Fördelar: Minskar trötthet, halksäker, UV-stabil

⑦ PU-beläggning för parker och kommunala vägar (halkskyddad färgad beläggning)

- Funktioner: Lösningsmedelsfri, halksäker, brusreducerande, livfulla färger

- Tillämpningar: Parker, gångvägar, torg, utomhusparkering

- Fördelar: Väderbeständig, långvarig färghållning

⑧ Väderbeständig PU-beläggning för utomhusställ och pooler

- Funktioner: UV-beständig, vattentät, kemikaliebeständig (klorin/saltvatten)

- Tillämpningar: Sittplatser på stadion, simbassänger, vattenparker

- Fördelar: Ingen blekning, stark vidhäftning, antimögel

Vanliga frågor och svar (FAQ):

F1: Vad är den största skillnaden mellan golvbeläggningar av epoxi och polyuretan?

Detta är en av de mest efterfrågade frågorna i världen.

A: Båda är högpresterande beläggningar, men de har olika primära funktioner. Epoxibeläggningar är kända för sin exceptionella vidhäftning, hållbarhet och bärighet, vilket gör dem till en idealisk basbeläggning. Polyuretanbeläggningar är uppskattade för sin överlägsna UV-stabilitet, kemikaliebeständighet och nötningsbeständighet. De är också mer flexibla och ger en jämnare, ofta glansigare, yta. De bästa systemen kombinerar ofta båda: en epoxibas för styrka och en polyuretantopplack för skydd och estetik.

F2: Är polyuretangolv resistenta mot kemikalier och fläckar?

Sökord: "kemikaliebeständig golvbeläggning", "syrafast golv".

A: Ja, utmärkt motståndskraft är en viktig anledning till deras popularitet. Polyuretanbeläggningar bildar en icke-porös, sömlös yta som är mycket motståndskraftig mot ett brett spektrum av kemikalier, inklusive oljor, fetter, bränslen, lösningsmedel och många syror och alkalier. Detta gör dem till ett förstahandsval för livsmedels- och dryckesanläggningar, bilverkstäder, laboratorier och läkemedelsanläggningar där spill är vanligt förekommande.

F3: Kommer en polyuretanbeläggning att gulna eller blekna i direkt solljus?

Sökord: "UV-beständigt garagegolv", "gulnande golvbeläggning".

A: Till skillnad från standard epoxi, som kan krita och gulna under UV-exponering, är alifatiska polyuretanbeläggningar speciellt formulerade med överlägsen UV-stabilitet. De är utformade för att behålla sin färg och glans i flera år, även i direkt solljus. Det gör dem perfekta för flyghangarer, lagerlokaler med takfönster och uteplatser eller balkonger utomhus.

Q4: Hur länge håller en golvbeläggning av polyuretan?

Sökord: "polyuretangolvets livslängd", "hur länge håller beläggningen på garagegolvet".

A: Livslängden beror i hög grad på ytbehandling, installationskvalitet och trafiknivåer. En professionellt applicerad topplack av polyuretan över ett epoxisystem kan hålla i 10-20 år i industriella eller kommersiella miljöer. I högtrafikerade områden som lagerlokaler kan det krävas en uppfräschning vart 5-10 år. Korrekt underhåll är avgörande för att maximera dess livslängd.

F5: Är ett golv av polyuretan halt? Är det halksäkert?

Sökord: "halkfritt garagegolv", "halksäkert industrigolv".

A: En blank polyuretanfinish av standardtyp kan vara hal när den är våt. Halkbekämpande tillsatser (t.ex. polymergrit eller kvartssand) kan dock enkelt spridas i den våta beläggningen för att skapa en strukturerad, halksäker yta. Detta är en viktig säkerhetsfunktion för områden som storkök, pooldäck och tillverkningsanläggningar.

F6: Kan jag applicera polyuretanbeläggning själv, eller behöver jag en professionell?

Sökord: "DIY polyuretan golvkit", "professionell golvbeläggning".

A: Det finns visserligen DIY-kit, men det är en stor utmaning att uppnå ett hållbart, professionellt resultat. Korrekt applicering kräver ** noggrann ytbehandling (ofta inklusive diamantslipning), strikt kontroll av luftfuktighet och temperatur samt expertteknik för blandning och applicering**. För alla kommersiella, industriella eller garageapplikationer rekommenderar vi starkt att man anlitar en certifierad professionell installatör.

F7: Vad är den typiska härdnings- och stilleståndstiden för ett polyuretangolv?

Sökord: "härdningstid för golvbeläggning", "hur länge innan jag kan köra på garagegolvet".

A: Polyuretanbeläggningar är vanligtvis beröringstorkade inom 4-8 timmar. Lätt gångtrafik är vanligtvis möjlig efter 12-24 timmar. Fullständig härdning (uppnående av maximala kemiska och mekaniska egenskaper) kan dock ta 3-7 dagar. Det rekommenderas att man väntar minst 72 timmar innan man flyttar tung utrustning eller parkerar fordon på ytan. Följ alltid tillverkarens specifika riktlinjer.

F8: Kan polyuretan appliceras över ett befintligt epoxigolv?

Sökord: "omlackering av gammalt epoxigolv", "topplack av polyuretan".

A: Ja, absolut. Det här är en mycket vanlig och starkt rekommenderad metod för att föryngra ett gammalt, slitet eller gulnat epoxigolv. Det befintliga epoxigolvet måste rengöras ordentligt, slipas lätt (t.ex. genom blästring eller diamantslipning) och avfettas så att det nya toppskiktet av polyuretan får en stark vidhäftning.

F9: Vilket underhåll krävs för ett golv av polyuretan?

Sökord: "hur man rengör polyuretangolv", "underhåll av industrigolv".

A: Underhållet är enkelt. Regelbunden sopning eller dammtorkning avlägsnar slipande skräp. För rengöring, använd ett rengöringsmedel med neutralt pH-värde och en mjuk borste eller en automatisk skurmaskin. Undvik starka sura eller alkaliska rengöringsmedel, eftersom de kan försämra ytan över tid trots dess höga motståndskraft. Det är alltid rekommenderat att torka upp spill omedelbart.

Q10: Vilka typer av miljöer är polyuretanbeläggningar bäst lämpade för?

Sökord: "bästa beläggning för livsmedelsfabriksgolv", "garage golvbeläggning för kallt klimat."

A: På grund av sin kombination av egenskaper är polyuretanbeläggningar det föredragna valet för:

- Bearbetning av livsmedel och drycker: USDA- och FDA-kompatibel, lätt att rengöra, kemikalieresistent.

- Fordon och flygplansindustri: Motståndskraftig mot hydraulvätskor, jetbränsle och heta däck.

- Lager & logistik: Tål tung fot- och gaffeltruckstrafik utan att slitas ned.

- Kommersiellt och detaljhandel: Högblankt, estetiskt tilltalande för utställningslokaler och offentliga utrymmen.

- Utomhus: UV-stabilitet för områden som utsätts för solljus.

KAIDA JINYU PAINT Uretanbeläggning Projekt

Hur tillverkas utvalda JINYU-färger?

JINYU® har ett brett utbud av färgalternativ och anpassningsmöjligheter. Färgexperter arbetar i nära samarbete med kunderna för att skapa unika nyanser och ytbehandlingar som passar deras specifika projekt.

Användningsområden för utvalda JINYU PAINT® -färger

JINYU PAINT® erbjuder ett omfattande sortiment av högpresterande ytbeläggningar, inklusive epoxigolvbeläggningar, industriella ytbeläggningar, brandsäkra ytbeläggningar och arkitektoniska ytbeläggningar för inner- och ytterväggar. Våra lösningar är utformade för hållbarhet, estetik och skydd i olika tillämpningar, från bostäder och kommersiella byggnader till industrianläggningar och brandsäkerhetsprojekt. Oavsett om du behöver sömlösa golv, korrosionsbeständighet, brandskydd eller dekorativa väggytor, erbjuder JINYU PAINT® expertbeläggningar för att förbättra och skydda alla ytor.

SENASTE FRÅGOR hos JINYU PAINT®

VANLIGA FRÅGOR

- Hur man förebygger skador orsakade av termisk chock i golv för livsmedelsbearbetning: Lösningen med urethanbetong

- 7 expertstrategier för att förlänga livslängden på polyuretangolv i områden med hög trafik

- Hur man fixar skalande eller delaminerande polyuretangolv: En definitiv reparationsguide

- Vilka är de bästa metoderna för att installera polyuretangolv i ett farmaceutiskt renrum?

- Vilken typ av golv passar bäst för logistiklager med gaffeltruckstrafik?

Kontakta oss

Kontaktpersoner: Sabella Wei

Telefon: 86-022-83859963

Whatsapp: 15822925523