Beskrivning

Produktöversikt

Polypro™ XT Topcoat AC is a high-performance, seamless urethane flooring system specifically engineered for the most demanding industrial environments. By combining advanced polyurethane resin technology, this system forms a tough, flexible, and dense protective layer. It boasts exceptional abrasion and impact resistance, outstanding chemical tolerance, and long-lasting color and gloss stability. It provides a durable, safe, and easy-to-maintain flooring solution for warehouses, manufacturing plants, food processing facilities, and commercial spaces.

Common Industrial Flooring Pain Points and Challenges

Industrial and commercial facility floors face constant challenges. Traditional concrete or inferior coatingsolutions often fail under stress, leading to:

Cracking and Dusting: Unsealed concrete is porous, generating dust that contaminates products and air quality, while susceptible to cracking from substrate movement or impact.

Chemical Attack and Staining: Exposure to oils, fuels, acids, solvents, and cleaning chemicals can degrade many flooring materials, causing etching, discoloration, and weakening of the coating.

Mechanical Wear and Tear: Constant traffic from heavy machinery, steel-wheeled carts, and foot traffic leads to rapid wear, scuffing, and loss of surface integrity in standard paint or epoxy finishes.

Moisture and Hygienic Issues: Moisture vapor emission from slabs can blister coatings, while porous surfaces harbor bacteria, making cleaning difficult and compromising hygiene in sensitive areas like industrial kitchens or labs.

Säkerhetsrisker: Slippery surfaces when wet or oily pose significant slip-and-fall risks. Poor finish durability can also create tripping hazards from surface degradation.

Polypro™ XT Topcoat AC: Your Comprehensive Flooring Solution

The Polypro™ XT Topcoat AC urethane flooring system is designed to directly address these challenges, offering a superior, long-lasting finish.

Core Features & Benefits:

Oöverträffad hållbarhet: Formulated with high-performance polyurethane and resin, it delivers superior resistance to abrasion, impact, and heavy point loads, far outperforming standard epoxy coatings.

Överlägsen kemisk resistens: Effectively resists a wide range of chemicals including oils, greases, fuels, dilute acids, alkalis, and salts, protecting your betong substrate and ensuring easy cleanup.

Sömlös och hygienisk: Creates a completely monolithic surface with no joints or grout lines where dirt and moisture can accumulate, promoting superior hygiene and ease of cleaning.

Förbättrad säkerhet: Can be formulated with anti-slip aggregates to provide a high-traction surface, meeting slip-resistance standards (e.g., R9-R11) for wet and oily environments.

Aesthetic Versatility: Available in a wide range of standard and custom colors, with gloss, semi-gloss, and satin finish options to suit any facility’s aesthetic requirements.

Utmärkt UV-stabilitet: Unlike many epoxy systems, the polyurethane topcoat offers excellent resistance to yellowing and gloss loss from UV exposure, making it suitable for areas with natural light.

Fast Cure & Low VOC: Many formulations feature rapid cure times, minimizing facility downtime. Water-based and low-VOC options are available for environmentally sensitive projects.

Tekniska specifikationer Data

The performance of the Polypro™ XT Topcoat AC system is backed by rigorous testing. Below are typical physical properties:

| Fastighet | Testmetod | Result / Performance |

|---|---|---|

| Motståndskraft mot nötning | ASTM D4060 (CS-17 Wheel) | ≤ 40 mg loss after 1000 cycles |

| Adhesion (to concrete) | ASTM D4541 / Pull-Off | > 300 psi (Concrete substrate failure) |

| Hårdhet | ASTM D2240 (Shore D) | 75 – 85 |

| Kemisk beständighet | Immersion per ASTM D1308 | Excellent resistance to oils, greases, salts, dilute acids & alkalis |

| Motståndskraft mot stötar | ASTM D2794 | No cracking or disbondment from direct/reverse impact |

| Flexural Strength | ASTM D790 | High, accommodating minor substrate movement |

| Slip Resistance (Wet) | DIN 51130 / ASTM E303 | Customizable (R9, R10, R11 ratings available) |

| Temperatur vid drift | - | -40°F to +250°F (Continuous) |

Note: Specific values may vary based on system configuration (e.g., basecoat type, thickness). Consult technical data sheets for project-specific specifications.

Tillämpningsområden

The versatility of the Polypro™ XT Topcoat AC system makes it the ideal choice across numerous industries:

Bearbetning av livsmedel och drycker: Withstands chemical spills, thermal shock, and frequent high-pressure washdowns. USDA and FDA compliant options available.

Pharmaceutical & Biotechnology: Provides a seamless, non-porous, and cleanable surface for GMP environments. Can be formulated for static-control (ESD).

Lagerhållning och logistik: Handles extreme abrasion from forklift traffic and heavy pallet drops without wearing through.

Fordon och flygplansindustri: Resists fuels, hydraulic fluids (like Skydrol™), brake fluids, and tire marks. Ideal for hangars, service bays, and showrooms.

Manufacturing & Industrial Plants: Durable against mechanical abuse and chemical exposure in heavy industrial settings.

Commercial & Institutional: Aesthetic, durable, and safe for schools, hospitals, retail spaces, and public corridors.

Installation Process & Technical Support

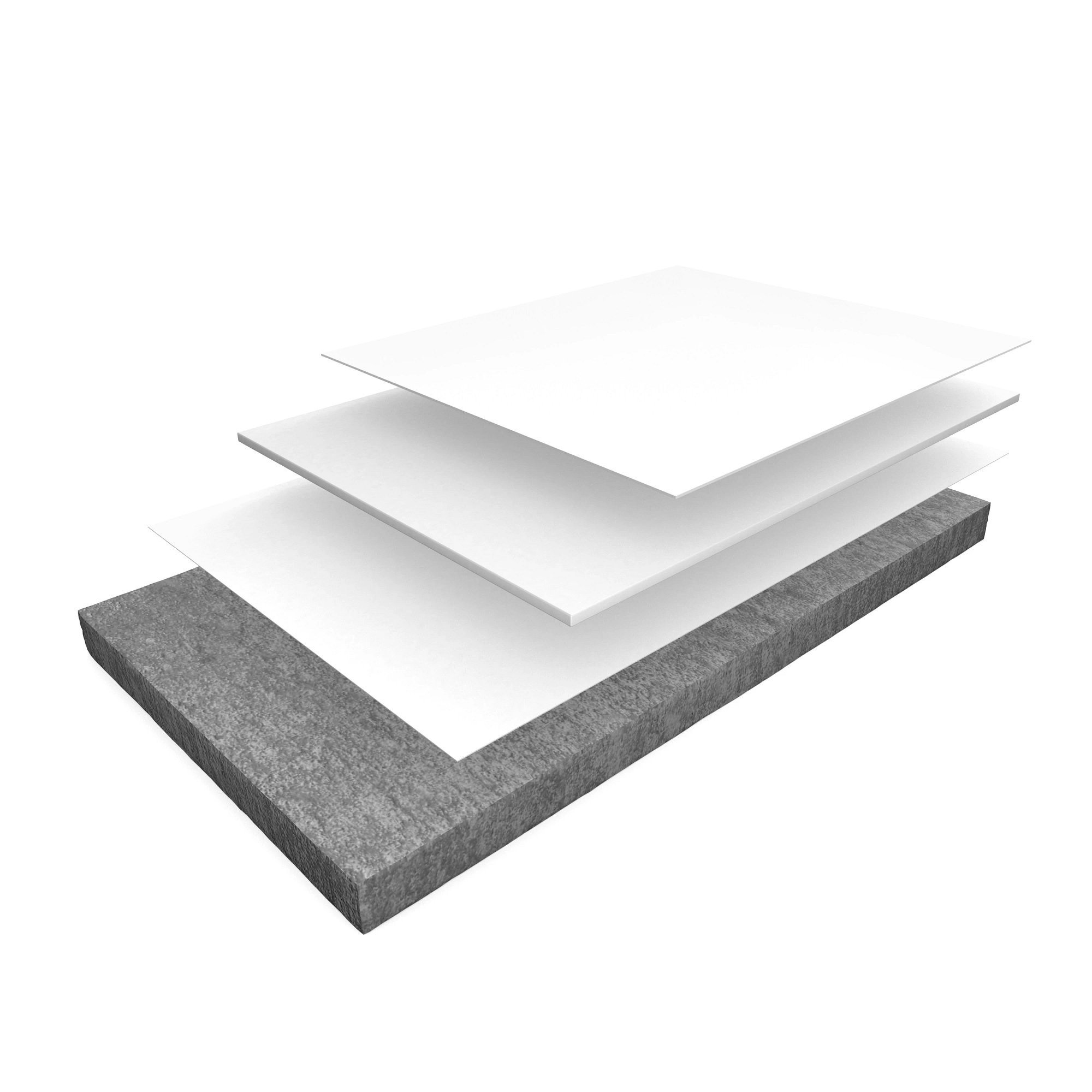

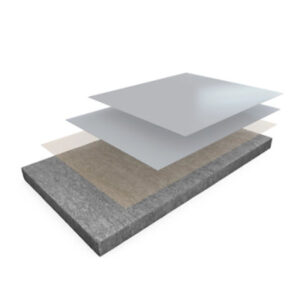

A successful installation relies on proper preparation and execution. While specific steps depend on the substrate and system design, a typical process involves:

Förberedelse av ytan: Critical first step. Concrete must be mechanically profiled (e.g., shot blasting) to a CSP 1-3 profile, clean, dry, and sound. Moisture testing (per ASTM F1869/F2170) is mandatory.

Primer/Basecoat Applicering: A primer or basecoat is applied to seal the substrate and enhance adhesion of subsequent layers.

Intermediate Coat (Optional): For added thickness, impact resistance, or slope correction, a mortar or self-leveling underlayment may be applied.

Polypro™ XT Topcoat AC Application: The high-performance urethane topcoat is applied via roller or squeegee to achieve a uniform, seamless finish. Anti-slip additives can be broadcast if required.

Curing & Protection: The system requires a specified cure time (typically 24-72 hours for light traffic) before full operational use. Temperature and humidity must be controlled during application and cure.

We Are Your Solution Partner: We provide more than just products. Our support includes:

Free Project Assessment: Our experts evaluate your substrate and requirements.

Detailed Specification & System Design: We recommend the optimal system configuration.

Professional Installer Network: We can connect you with certified, experienced contractors.

On-Site Technical Guidance: Our representatives offer support during critical phases of the installation.

Vanliga frågor och svar (FAQ)

Q: What is the main difference between Polyurethane and Epoxy Flooring?

A: While both are resinous floorings, polyurethane systems generally offer superior flexibility (better resistance to thermal cycling and micro-cracking), enhanced UV stability (won’t yellow), better abrasion resistance, and often higher chemical resistance to a broader range of substances compared to standard epoxy. Epoxy typically provides higher compressive strength and adhesion on marginally prepared surfaces.

Q: How long does it take to install a Polypro™ XT Topcoat AC system?

A: Project duration depends on area size, substrate condition, and system thickness. A typical 3-coat system over properly prepared betong can be installed over 3-5 days, with light foot traffic possible in 24-48 hours. Full cure for heavy traffic may take up to 5-7 days.

Q: What maintenance is required for polyurethane flooring?

A: Maintenance is simple. Regular sweeping or damp mopping with a neutral pH cleaner is usually sufficient. Avoid harsh abrasive cleaners or solvents. Immediate cleanup of chemical spills is recommended. Periodic re-application of a maintenance sealer (every few years, depending on traffic) can extend the high-gloss life.

Q: Can Polypro™ XT be applied over an existing epoxy floor?

A: Yes, it is an excellent urethane top coat over epoxy. It can rejuvenate a worn or yellowed epoxy floor, providing enhanced UV and chemical protection. Proper surface profiling and cleaning of the existing epoxy are essential for adhesion.

Q: What is the typical cost of a polyurethane floor coating?

A: The cost varies significantly based on substrate condition, system design (thickness, additives), project size, and geographic location. It is generally a premium investment compared to standard paints but offers far greater longevity and performance, resulting in a lower total cost of ownership. Contact us for a detailed quote.

Proof of Performance

Case Studies: We have successfully implemented the Polypro™ XT system in Fortune 500 manufacturing plants, international logistics hubs, and major food processing facilities.

Certifications & Standards: Our formulations are tested to meet or exceed relevant international standards for abrasion, chemical resistance, and slip resistance.

Industry Partnerships: We are the specified supplier for leading companies in automotive, aerospace, and food production sectors.

About KAIDA PAINT

At KAIDA PAINT, we understand that your facility’s floor is a critical asset. It must withstand immense pressure, ensure safety, and support productivity day in and day out. That’s why we’ve dedicated ourselves to formulating and delivering advanced coating systems like the Polypro™ XT Topcoat AC.

We are more than just a paint manufacturer; we are your strategic partner in infrastructure durability. Our advantage lies in our deep material science expertise, allowing us to create urethane and epoxy solutions that are precisely engineered for real-world industrial challenges—be it chemical spillage in a processing plant, relentless impact in a distribution center, or stringent hygiene demands in a pharmaceutical lab.

We back our products with unparalleled support: from initial specification guidance and substrate analysis to connecting you with our network of certified application contractors. When you choose KAIDA PAINT, you invest in a system supported by a team committed to your project’s success and your floor’s long-term performance.

Your challenge has a solution. Let’s discuss how the Polypro™ XT Topcoat AC system can be tailored to meet your specific needs. Contact our flooring experts today for a comprehensive consultation and quote.