Descripción

Productos

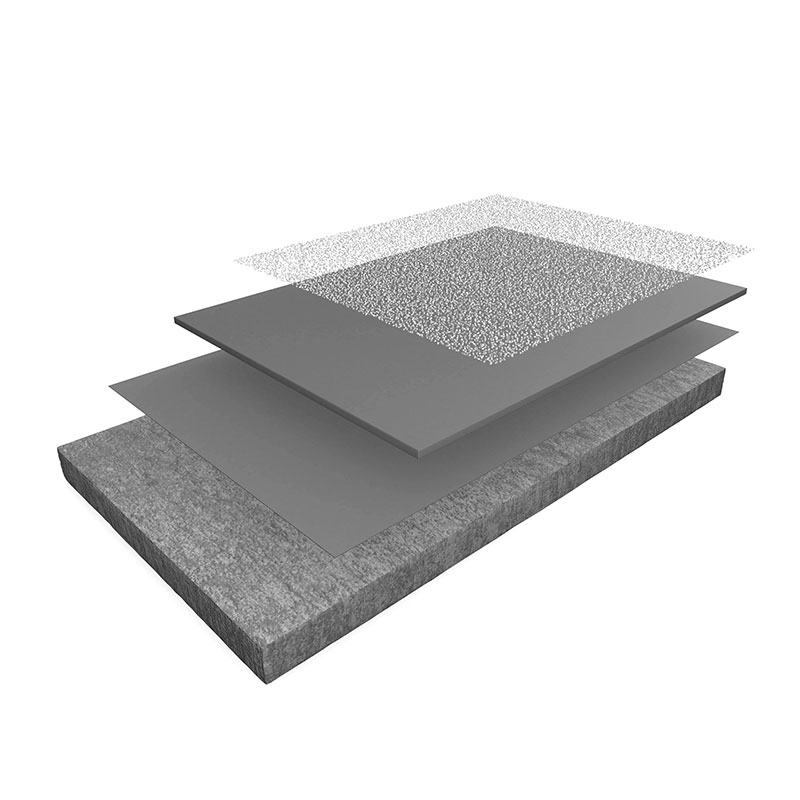

The ResuShield™ XT MCS is a high-performance, moisture-control system designed as an epoxy underlayment for concrete. This water-based, self-leveling coating is engineered to mitigate moisture vapor emissions from slabs, creating a stable base for subsequent non-permeable flooring finishes. It combines a specially formulated resin and aggregate blend to deliver excellent compressive strength and moisture insensitivity. Ultimately, it provides a reliable solution for repairing, leveling, and sealing concrete in industrial, commercial, and institutional settings, ensuring a long-lasting foundation.

Common Industrial Flooring Problems & How ResuShield XT MCS Solves Them

Industrial and commercial floors face relentless challenges. Understanding these pain points is key to selecting the right system.

Moisture Damage & Vapor Emission: Unchecked moisture rising through a concrete slab can blister and delaminate standard epoxy coatings, leading to costly repairs and downtime. The ResuShield XT MCS is specifically designed to shield the flooring system from these emissions.

Crack Bridging & Subfloor Imperfections: Existing cracks and an uneven base can telegraph through and compromise the final finish. This system fills voids and levels the surface, providing a smooth canvas.

Chemical Spills & Corrosion: Facilities like warehouses, kitchens, and manufacturing plants expose floors to oils, greases, and cleaning agents. A proper underlayment enhances the overall chemical resistance of the entire floor build-up.

Hygiene & Cleanliness Concerns: In food processing, pharmaceuticals, or cleanrooms, a seamless, non-porous surface is critical to meet sanitation standards and facilitate easy cleaning.

ResuShield™ XT MCS: Core Features & Benefits

This epoxy flooring system is more than just a sealer; it’s an integral component of a high-performance floor.

Superior Moisture Control: The primary function. It shields sensitive top flooring from vapor drive, preventing adhesion failure.

Excellent Physical Properties: Delivers high compressive strength and durability to withstand heavy loads and industrial traffic.

Seamless & Self-Leveling: Creates a monolithic, smooth surface that is easy to clean and eliminates dirt traps. The self-leveling property ensures a uniform finish with minimal labor.

Water-Based & Low VOC: Easier and safer for installers to handle during application, with less odor and environmental impact compared to solvent-borne products.

Versatile Substrate Prep: Can be applied over properly prepared concrete following a CSP 4-6 surface profile, as outlined in our technical application guidelines.

Technical Data & Performance

The following table summarizes key performance metrics for the ResuShield XT MCS system, providing contractors and specifiers with the authoritative data needed for project planning.

| Parámetro | Specification / Performance | Test Method / Note |

|---|---|---|

| Tipo de sistema | Water-Based, Self-Leveling Epoxy Moisture Control | – |

| Theoretical Coverage (Primer) | 200-250 sq ft/gal | For 6-8 mils WFT |

| Theoretical Coverage (Slurry) | ~90 sq ft per 2.5 gal mix | At 1/8″ thickness |

| Required Surface Profile | CSP 4-6 | ICRI Guideline |

| Application Temperature | 50°F – 90°F (10°C – 32°C) | Substrate & ambient |

| Resistencia a la compresión | Excellent (High) | Product Data Sheet |

| Moisture Vapor Emission | Withstands high levels | Designed for remediation |

| Embalaje | 1.25 gal, 25 gal kits | Resin, hardener, aggregate |

Ideal Applications & Industries

The ResuShield XT MCS system is the trusted choice for a multitude of demanding environments where moisture is a concern:

Logistics & Warehousing: Creates a stable base for industrial floors in warehouses that must withstand heavy pallet racking and constant forklift traffic.

Procesado de alimentos y bebidas: Provides a critical moisture barrier under chemical-resistant topcoats in kitchens, bottling plants, and cold storage areas.

Comercial y minorista: Ideal as an underlayment for decorative epoxy or polyurethane systems in showrooms, retail spaces, and garages.

Healthcare & Institutional: Used in hospitals, schools, and laboratories to prepare slabs for seamless, hygienic flooring.

Basement & Below-Grade: Effectively controls dampness in basement conversions, parking garages, and other below-grade applications.

Professional Installation Process

For optimal performance, installation by approved professional contractors is recommended. Key steps include:

Surface Preparation (Prep): Concrete must be abrasive blasted to a CSP 4-6 profile. All contaminants, laitance, and imperfections must be removed or repaired.

Priming: En primer (Resuflor 3460) is mixed and applied via spray, roller, or brush to seal the substrate and ensure optimal adhesion.

Slurry Coat & Broadcast: The mixed slurry, containing aggregate, is poured and spread. It is immediately broadcast with silica sand to achieve the desired thickness (e.g., 1/8″).

Curing: The system requires a minimum 18-hour cure time under controlled conditions before applying the final flooring finish.

Important: Always consult the official application instructions and Safety Data Sheets (SDS) prior to starting any project.

Preguntas más frecuentes (FAQ)

Q: Can ResuShield XT MCS be used as a final wear surface?

A: No. It is designed as a moisture-control underlayment. A chemical-resistant topcoat or other impermeable flooring finish (like epoxy, polyurethane, or vinyl) must be applied over it for complete system performance.

Q: What is the typical system cost per square foot?

A: The cost varies based on slab condition, project size, and geographic location. It includes material, prep, and labor. For an accurate quote, contact us with your project details.

Q: How does it compare to other moisture mitigation products?

A: Unlike simple sealers, ResuShield XT MCS is a thick, load-bearing system that levels the substrate while controlling vapor. It offers a more robust solution than sheet membranes in many industrial settings.

Q: What maintenance does the installed system require before the topcoat?

A: Once cured, it requires minimal maintenance. Keep it clean and free from contamination before the final flooring application. Refer to our general maintenance guide for care after the full system is installed.

About KAIDA PAINT in High-Performance Flooring Solutions

KAIDA PAINT is a leading manufacturer and solution provider specializing in advanced industrial and commercial floor coating systems. With a commitment to innovation, quality, and technical excellence, we develop products like the ResuShield™ XT MCS to solve real-world challenges faced by facility managers, contractors, and companies worldwide.

Our expertise extends beyond formulating superior epoxy and polyurethane resins. We offer end-to-end project support, from initial site assessment and system design to detailed application guidance and maintenance planning. We understand that a successful flooring project depends on the right product, proper preparation, and professional installation. That’s why we work closely with a network of certified installers and provide unparalleled technical service.

Whether you’re managing a warehouse, a food processing plant, a parking garage, or a commercial facility, KAIDA PAINT has the system and the expertise to deliver a floor that combines durability, safety, and aesthetics. Stop searching for fragmented solutions. Partner with KAIDA PAINT for a comprehensive, reliable, and high-performance flooring outcome. Contact our team of experts today to discuss your project requirements and receive a customized proposal.