Descripción

ResuShield™ Deco Quartz TQ is a trowel-applied decorative quartz epoxy flooring system designed for high-traffic commercial and industrial interiors. Combining high-solids epoxy resins with colored quartz aggregate, it creates a seamless, impervious, and exceptionally durable floor surface. This system delivers superior abrasion resistance, heavy-duty performance, and easy maintenance. It is the ideal flooring solution for facilities requiring a combination of long-lasting durability, chemical resistance, and a visually appealing finish, such as food processing plants, pharmaceutical cleanrooms, laboratories, schools, and healthcare environments.

Common Industrial Flooring Problems & How ResuShield™ Deco Quartz TQ Solves Them

Industrial and commercial floors face relentless challenges that standard coatings can’t withstand. These problems lead to frequent repairs, safety hazards, and operational downtime.

Cracking and Impact Damage: Heavy equipment and constant traffic cause cracks in brittle floors.

Dusting and Degradation: Untreated or worn concrete creates dust, contaminating sensitive environments.

Ataque químico: Spills of oils, acids, solvents, and cleaning agents degrade floor coatings.

Slip Hazards and Difficult Cleaning: Porous or improperly sealed floors harbor bacteria and become slippery.

Poor Aesthetics and Morale: Dull, damaged floors negatively impact the perception of a facility.

The ResuShield™ Deco Quartz TQ system is engineered to address these exact pain points for contractors and facility managers, providing a robust, long-term flooring solution that protects your substrate and your business.

ResuShield™ Deco Quartz TQ: Core Features & Benefits

This high-performance system offers a complete package of mechanical, chemical, and physical properties.

Unmatched Durability & Mechanical Strength:

Extreme Abrasion Resistance: With a Taber Abrasion result of only 5.1 mg loss (CS-17 wheel, 1000g, 1000 revs), it far outperforms standard epoxy coatings.

High Load-Bearing Capacity: A compressive strength of 11,000 psi (ASTM C 579) handles heavy static and dynamic loads.

Superior Adhesion: Excellent bond to concrete, with adhesion tests resulting in concrete substrate failure (450+ psi per ASTM D4541).

Impact & Crack Resistance: The quartz aggregate and epoxy matrix provide resilience against dropping of tools and materials.

Exceptional Chemical & Stain Resistance:

The seamless, non-porous surface resists a wide range of chemicals, including oils, greases, and many acids and alkalis, facilitating easy cleaning and sanitation. For specific chemical exposure, consult our technical guide to select the optimal topcoat.

Enhanced Safety & Cleanability:

Slip-Resistant Options: Available with additives to achieve desired wet static coefficient of friction (SCOF) for safer environments like locker rooms and kitchens.

Seamless & Impervious: No grout lines or pores to trap dirt, moisture, or bacteria, making it ideal for hygienic facilities.

Easy to Clean: Smooth surface allows for quick wash-downs, reducing maintenance time and cost.

Aesthetic Flexibility & Customization:

Wide Color Selection: Choose from standard pre-blended colors or request custom color matching to fit any design scheme.

Finish Options: The standard system features a satin, high-wear urethane topcoat (Resutile™ HTS 100). Gloss urethane topcoats are also available.

Decorative & Functional: The colored quartz aggregate provides a consistent, attractive speckled appearance that also contributes to the floor’s durability.

Technical Data & Performance Specifications

The following data, based on independent laboratory testing under standard conditions (77°F / 25°C), validates the system’s performance.

| Propiedad | Método de ensayo | Result / Value |

|---|---|---|

| Resistencia a la abrasión | ASTM D4060 (Taber Abraser) | 5.1 mg loss |

| Dureza (Shore D) | ASTM D2240 | 80-85 @ 0 sec | 75-80 @ 15 sec |

| Resistencia a la compresión | ASTM C 579 | 11,000 psi |

| Tensile Strength (Binder) | ASTM D2370 | 8,000 psi |

| Adhesion to Concrete | ASTM D4541 | 450 psi (Concrete Failed) |

| Inflamabilidad | ASTM D635 | 182 mm/min |

| VOC Content (System) | ASTM D3960 | Low-VOC Formulation |

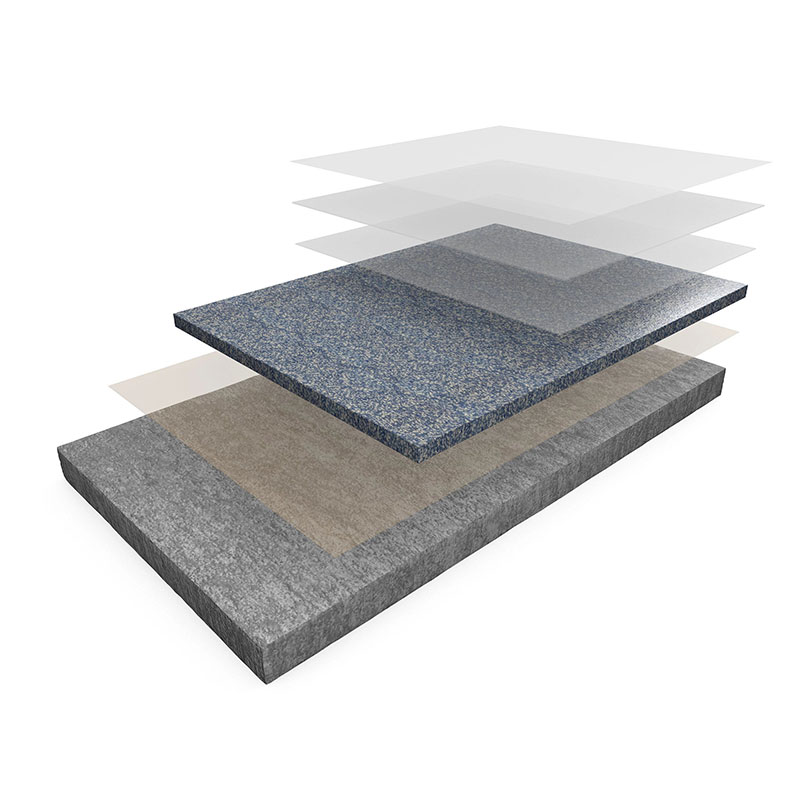

System Build-Up:

Cartilla: ResuShield™ MPE (7-9 mils)

Troweled Quartz Layer: ResuShield™ MPE + Trowel-Grade Quartz (3/16″)

Grout/Build Coats: ResuShield™ UVE (2 coats, ~18 mils total)

Capa superior: Resutile™ HTS 100 Satin Urethane (3 mils) or Gloss Option

Ideal Applications for ResuShield™ Deco Quartz TQ

This versatile system is specified by architects and contractors for demanding environments across numerous industries:

Healthcare & Pharmaceutical: Hospitals, clinics, cleanrooms. Needs seamless, cleanable, and chemical-resistant floors.

Comida y bebida: Processing plants, breweries, kitchens. Requires USDA-compliant, grease-resistant, and sanitary surfaces.

Educational & Institutional: Schools, universities, laboratories. Demands durable, low-maintenance, and safe flooring.

Commercial & Light Industrial: Warehouses, parking garages, showrooms. Benefits from high abrasion resistance and aesthetic appeal.

Wet Areas: Locker rooms, showers, bathrooms. Needs waterproofing and slip resistance.

Professional Installation Process & Support

A successful, long-lasting floor depends on proper installation by qualified professionals. The key steps include:

Surface Preparation & Inspection: Concrete must be sound, clean, and shot-blasted to a CSP 4-6 profile (ICRI 310.2R). Moisture testing (ASTM F2170) is critical.

Aplicación de imprimación: ResuShield™ MPE primer is applied to ensure optimal adhesion.

Quartz Mortar Installation: The blended quartz and epoxy mortar is troweled to a consistent 3/16″ thickness.

Grout & Build Coats: Multiple coats of ResuShield™ UVE epoxy are applied to fill voids and build thickness.

Aplicación de la capa final: The final urethane topcoat (Resutile™ HTS 100) is rolled on for maximum wear and chemical resistance.

Our Commitment: We provide comprehensive technical support, including specification guidance, on-site consultation for contractors, and detailed product data sheets to ensure a flawless installation from prep to finish.

Preguntas más frecuentes (FAQ)

Q: What is the main advantage of ResuShield™ Deco Quartz TQ over a standard epoxy coating?

A: The high load of quartz aggregate provides significantly higher abrasion resistance, durability, and the ability to accommodate minor substrate irregularities, making it far more robust for heavy industrial use.

Q: How long does the installation process take?

A: Timeline depends on area size and conditions. Typically, after concrete prep, the coating system requires several days for application and cure time before light traffic (24 hours) and full service (7-14 days).

Q: Can this system be installed in a basement or over existing tile?

A: It is designed for interior concrete slabs. Proper evaluation of the basement’s moisture levels is essential. It can be installed over sound, properly prepared existing tile, but substrate analysis is required.

P: ¿Qué mantenimiento requiere?

A: Maintenance is simple. Regular sweeping and occasional mopping with neutral pH cleaners are usually sufficient. Avoid harsh abrasive cleaners.

Q: Is this a DIY-friendly product?

A: No. Due to the critical need for precise mixing, professional surface preparation, and skilled troweling to achieve a perfect finish, it must be installed by trained and experienced flooring contractors.

Trust & Proven Performance

ResuShield™ flooring systems are specified by leading companies and contractors worldwide for critical infrastructure projects. Our products are developed following stringent ASTM international standards, and our technical team brings decades of industry expertise. We partner with a network of professional applicators to deliver guaranteed results.

About KAIDA PAINT

Your Trusted Partner in High-Performance Flooring Solutions

KAIDA PAINT is a leading manufacturer and solution provider specializing in advanced resinous flooring systems for the most demanding industrial and commercial environments. We understand that your floor is a critical asset that impacts safety, productivity, and operational costs. That’s why we developed the ResuShield™ product line—engineered to deliver unmatched durability, chemical resistance, and longevity.

Our advantage lies in our dual commitment: formulating top-tier products like ResuShield™ Deco Quartz TQ and supporting the professional contractors who install them. We offer comprehensive technical specifications, on-site project support, and custom color solutions to ensure every project meets exacting standards. Don’t just buy a coating; invest in a partnership that guarantees a floor built to last. Contact our expert team today for a consultation, a detailed project quote, or to connect with a qualified installer in your area.

With extensive experience in the industrial and commercial flooring sector, we provide:

High-Quality, Reliable Products: Formulated for maximum performance and longevity.

Expert Technical Support: From specification to on-site application advice.

Custom Color Matching: To meet your exact design requirements.

Support for Professional Contractors: Ensuring successful project completion.

Whether you are a contractor bidding on a project or a facility manager planning an upgrade, we have the products and expertise to meet your needs. Get a quote, request a specification, or consult with our technical experts today.

Contact us now to discuss your project and discover the best flooring solution for your facility.