Description

Product Overview

ResuShield™ Screed TG46 II is a heavy-duty, nominal 1/4″ thick epoxy mortar flooring system designed to resurface and protect interior concrete floors in demanding industrial environments. This multi-layer system combines high-solids epoxy resins with silica aggregates to create a seamless, monolithic overlay that is trowel-applied for superior durability. It delivers exceptional resistance to abrasion, impact, and a wide range of chemicals. ResuShield™ Screed TG46 II is the ideal solution for companies seeking to extend the life of their concrete substrates, reduce maintenance costs, and ensure a safe, cleanable surface in facilities like manufacturing plants, warehouses, food processing areas, and more.

Industrial Flooring Challenges & How ResuShield™ Solves Them

Industrial and commercial floors face relentless abuse that standard paint or coatings cannot withstand. Common problems include:

Cracking & Damage: Heavy forklift traffic and dropped loads cause cracks and spalling in plain concrete.

Dusting & Degradation: Constant abrasion wears down surfaces, creating dust that contaminates products and equipment.

Chemical Attack: Spills of oils, solvents, acids, and cleaning agents degrade floors, leading to pitting and contamination.

Hygiene & Cleanliness Issues: Porous, cracked floors harbor bacteria, mold, and are difficult to sanitize, especially critical for food & beverage or pharmaceutical companies.

Moisture & Vapor Transmission: Moisture from the concrete slab can cause coating failures like blistering and delamination.

The ResuShield™ Screed TG46 II system is engineered specifically to address these pain points for contractors and facility managers. It provides a thick, impervious shield that protects your concrete investment, simplifies cleaning, and maintains a professional appearance under extreme conditions.

ResuShield™ Screed TG46 II Core Features & Benefits

1. Unmatched Durability & Mechanical Performance

This is not a thin coating; it’s a wear layer. The epoxy/aggregate mortar matrix provides:

Extreme Abrasion Resistance: With a Taber Abrasion loss of only 11.7 mg (CS-17 wheel, 1000 cycles), it far outperforms standard epoxy paints.

High Impact & Load Bearing: Excellent compressive strength (10,000+ psi) withstands heavy rolling loads and impacts without damage.

Superior Adhesion: The system bonds tenaciously to concrete, with adhesion tests resulting in concrete failure (450-732 psi), ensuring the coating stays in place.

2. Proven Chemical Resistance

The seamless, non-porous finish resists degradation from a broad spectrum of industrial chemicals, including oils, greases, mild acids, alkalis, and salts. This makes it perfect for drum storage areas, chemical processing zones, and automotive shops.

3. Seamless, Sanitary & Easy to Maintain

The monolithic finish has no joints or cracks for dirt, moisture, or bacteria to hide. It can be easily cleaned with standard industrial cleaners and is designed to withstand frequent wash-downs, supporting high hygiene standards.

4. Enhanced Safety

Slip Resistance: Available with added traction aggregate or specific topcoats to achieve desired slip-resistant ratings, even when wet.

Fire Performance: Tested per ASTM D635, contributing to overall facility safety.

5. Aesthetic Flexibility & Long-Lasting Finish

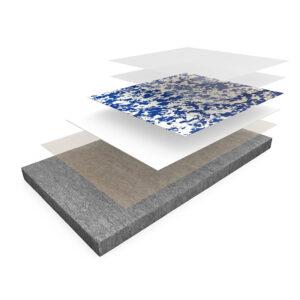

Custom Colors: Available in a wide range of standard and custom colors to meet branding or safety coding needs (e.g., aisle marking).

Texture Options: Can be finished to a smooth, satin surface or an “orange-peel” texture for added traction.

UV-Stable Topcoat: The optional aliphatic urethane topcoat (like Resutile HTS 100) provides excellent resistance to yellowing and maintains appearance.

6. Professional-Grade System Design

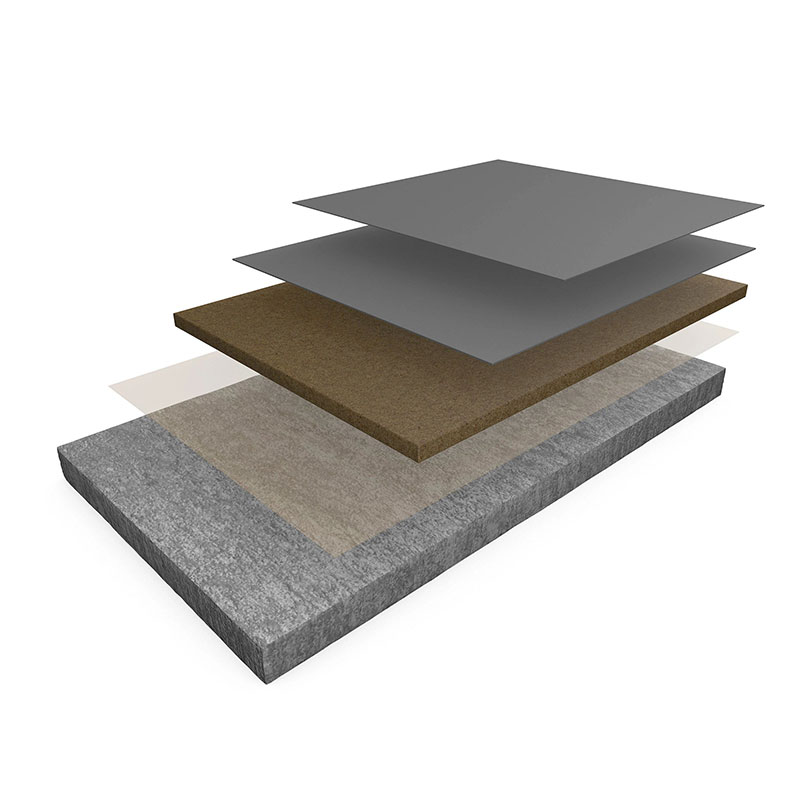

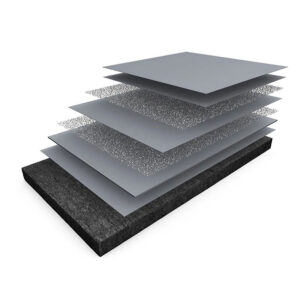

The 5-layer system ensures performance:

Primer (Resuflor MPE): Penetrates and seals the concrete substrate.

Mortar Layer (Resuflor MPE + Aggregate): Builds thickness and load-bearing strength.

Grout Coat (Resuflor PT Topcoat): Seals the mortar layer.

Build Coat (Resuflor MPE): Ensures a uniform surface.

Topcoat (Resutile HTS 100): Provides final wear, chemical resistance, and aesthetic finish.

Technical Specifications at a Glance

| Property | Test Method | Result/Value |

|---|---|---|

| System Thickness | Nominal | 1/8″ to 1/4″ (3-6 mm) |

| Abrasion Resistance | ASTM D4060 | 11.7 mg loss |

| Adhesion to Concrete | ASTM D4541 | 450 psi (concrete failure) |

| Adhesion to Concrete | ASTM D7234 | 732 psi |

| Compressive Strength | ASTM D695 (Resin) | 13,500 psi |

| Tensile Strength | ASTM D2370 (Resin) | 8,000 psi |

| Elongation (Resin) | ASTM D2370 | 6% |

| Hardness, Shore D | ASTM D2240 | 80-85 @ 0 sec / 75-80 @ 15 sec |

| VOC Content | ASTM D3960 | Low VOC (<50 g/L mixed) |

| Flammability | ASTM D635 | 182 mm/min |

Ideal Application Areas

The ResuShield™ Screed TG46 II system is specified by engineers and contractors for demanding environments:

Manufacturing & Industrial Plants: High-traffic aisles, production floors.

Warehousing & Logistics: Distribution centers, loading docks subject to constant pallet jack and forklift traffic.

Food & Beverage Processing: Areas requiring USDA/FDA-compliant, cleanable, and chemical-resistant floors.

Automotive & Aerospace: Garages, workshops, hangars exposed to fuels, oils, and heavy equipment.

Pharmaceutical & Biotechnology: Cleanrooms, labs, and processing areas needing seamless, contaminant-free surfaces.

Commercial Kitchens & Restaurants: Grease and stain resistance, ease of cleaning.

Parking Garages: Durable, wear-resistant surface for vehicular traffic.

Professional Installation & Support

Proper installation is critical to system performance. We recommend using our network of approved, experienced flooring contractors. Key installation steps include:

Surface Preparation: Concrete must be shot-blasted to a CSP 4-6 profile (ICRI 310.2R), clean, sound, and dry. Moisture testing (ASTM F2170) is required.

Primer Application: Apply epoxy primer to sealed substrate.

Mortar Installation: Mix and trowel-apply the epoxy/aggregate mortar to specified thickness.

Grout & Topcoat: Seal the mortar and apply the final wear-resistant topcoat.

Curing: Allow proper cure time before subjecting to service.

We provide comprehensive technical support, including specification guidance, jobsite consultation, and contractor training to ensure your project’s success.

Frequently Asked Questions (FAQ)

Q: How does ResuShield™ Screed TG46 II compare to a standard epoxy coating?

A: Standard epoxy paints are thin films (10-20 mils). ResuShield™ is a thick mortar system (125-250 mils) offering far greater durability, impact resistance, and longevity under severe conditions.

Q: What is the typical installation time and when can I use the floor?

A: Installation time varies with area size and conditions. The mortar requires 6-8 hours to cure before sealing at 75°F. The final topcoat typically needs 24 hours for light traffic and 7-14 days for full cure and heavy traffic.

Q: Can this system be applied over an existing damaged floor?

A: Yes, a primary use is resurfacing. The concrete must be properly prepared: cracks repaired, unsound material removed, and the surface profiled to ensure adhesion.

Q: How do I maintain my ResuShield™ floor?

A: Daily dust mopping and prompt spill cleanup are recommended. Periodic damp mopping or scrubbing with a mild, pH-neutral detergent maintains appearance. Avoid harsh acids or solvents not listed in the chemical resistance guide.

Q: What is the approximate cost per square foot?

A: The total installed cost depends on substrate condition, project size, location, and chosen contractor. As a heavy-duty system, it is an investment that reduces long-term repair and replacement costs. Contact us for a detailed quote.

Trust & Proven Performance

ResuShield™ systems are manufactured to the highest standards, backed by rigorous testing against ASTM international standards. Our products are specified by leading companies across industries for critical flooring applications. We partner with professional flooring contractors worldwide to deliver reliable, high-performance results.

Your Partner for High-Performance Flooring: KAIDA PAINT

At KAIDA PAINT, we are more than just a manufacturer; we are your solutions partner for industrial and commercial flooring challenges. With deep expertise in epoxy and polyurethane resin technologies, we develop products like the ResuShield™ Screed TG46 II that are engineered to perform in the toughest environments. Our commitment extends beyond supplying high-quality products to offering unmatched technical support, specification assistance, and access to a trained network of professional installers. Whether you’re a contractor bidding on a project or a facility manager planning an upgrade, we provide the products, knowledge, and support to ensure your floor delivers lasting value, safety, and performance.

Ready to specify or install the ultimate industrial flooring solution?

Contact KAIDA PAINT today for technical data sheets, a chemical resistance guide, a system sample, or to connect with a qualified installer in your area. Let us help you build a better, more durable foundation for your business.