Descripción

Product Overview: What is Ure-Crete™ HF?

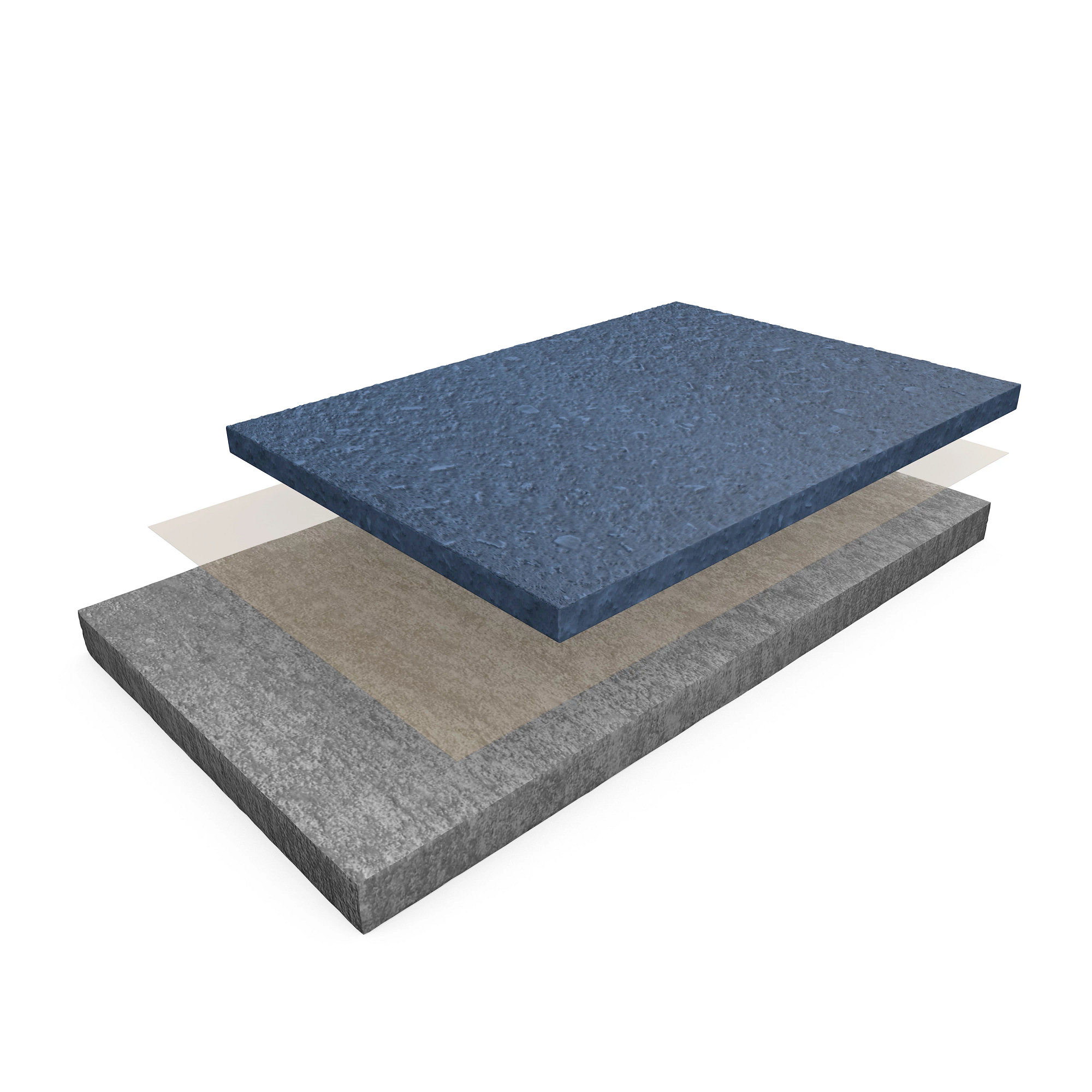

Ure-Crete™ HF is a 100% solids, trowel-applied, cementitious urethane concrete coating system designed for severe industrial service. It represents a hybrid technology where reactive polyurethane resins are combined with specialized cementitious aggregates and fillers. This fusion creates a dense, monolithic mortar that is applied directly onto concrete substrates. The resulting finish possesses a coefficient of thermal expansion nearly identical to concrete, granting exceptional resistance to thermal shock and preventing delamination. With superior abrasion, chemical, and impact resistance, Ure-Crete™ HF provides a long-lasting, low-maintenance flooring solution for areas subjected to extreme physical and environmental stress.

El reto de los suelos industriales: Puntos débiles comunes

Before investing in a new floor, it’s essential to understand the problems you’re solving. Here are the common pain points for companies and contractors managing industrial spaces:

Degradation from Chemical Attack: Spills of acids, alkalis, solvents, oils, and fats in food & beverage or chemical processing plants can quickly degrade standard floors, leading to safety hazards and costly repairs.

Mechanical Wear and Tear: Constant traffic from forklifts, steel-wheeled carts, and dropped tools causes abrasion, gouging, and dusting in warehouses and manufacturing installation areas.

Cracking and Impact Damage: Thermal cycling in freezer/cooler environments or heavy point-load impacts can cause traditional floors to crack and spall.

Hygiene and Cleanability: Porous or cracked floors harbor bacteria, mold, and dirt, creating sanitation nightmares for facilities requiring USDA or FDA compliance. Inefficient cleaning drains productivity.

Downtime and Cost: Frequent repairs and premature replacement of flooring systems lead to significant operational downtime, labor cost, and material waste.

Specific Scenario Needs:

Food & Beverage Plants: Need floors that withstand harsh sanitizers (quaternary ammonium, chlorine), hot water/steam cleaning, fatty acids, and sugar solutions while being seamlessly cleanable.

Warehouses & Logistics Centers: Require floors that resist abrasion from constant high-traffic, withstand heavy point loads from racking, and provide a durable surface that minimizes maintenance.

Instalaciones de fabricación: Demand resistance to hydraulic fluids, cutting oils, and occasional chemical spills, combined with high durability under rolling and static loads.

The Ure-Crete™ HF Solution: Core Features & Benefits

Ure-Crete™ HF is specifically formulated to address these industrial challenges head-on. Here’s how it delivers unparalleled value:

Durabilidad y resistencia excepcionales:

Abrasion Resistance: Withstands extreme wear from heavy traffic and rolling loads, dramatically outperforming standard epoxy systems.

High Impact Resistance: Absorbs blows from dropped tools and equipment without cracking or chipping.

High Compressive & Flexural Strength: Supports heavy static loads from machinery and storage racking.

Superior Chemical & Thermal Resistance:

Broad Chemical Resistance: Formulated to resist a wide range of acids, alkalis, salts, oils, and fats commonly found in industrial settings.

Thermal Shock Resistance: Its thermal expansion properties match concrete, making it ideal for environments with washdowns, steam cleaning, or freeze-thaw cycles without cracking or debonding.

Acabado sin costuras e higiénico:

Monolithic, Joint-Free Surface: Eliminates grout lines and seams where dirt and bacteria can accumulate, facilitating easier and more effective cleaning.

Impermeable Barrier: Creates a non-porous surface that resists stain penetration and inhibits microbial growth.

Enhanced Safety & Functionality:

Slip-Resistant Options: Can be finished with a texture or with broadcast aggregates to provide a high-traction surface, even when wet, meeting ANSI slip resistance standards.

FDA/USDA Compliant: Suitable for use in food processing areas where regulatory compliance is mandatory.

Practical Application Advantages:

100% Solids, Zero VOC: No harmful fumes during installation, allowing work to often continue in adjacent occupied spaces.

Tiempo de curado rápido: Allows for faster return to service compared to many cementitious systems.

Customizable: Available in a range of standard and custom colors to meet aesthetic or coding needs.

Technical Specifications & Authoritative Data

The performance of Ure-Crete™ HF is backed by rigorous standardized testing. The data below underscores its capability as a high-performance cementitious urethane mortar.

| Propiedad | Método de ensayo | Typical Value / Result |

|---|---|---|

| Tipo de sistema | - | 100% Solids, Cementitious Urethane Mortar |

| Application Thickness | - | 1/4″ to 3/8″ (6 mm to 9.5 mm) |

| Resistencia a la compresión | ASTM C-579 | 7,800 psi |

| Resistencia a la flexión | ASTM D-790 | 5,076 psi |

| Resistencia a la tracción | ASTM D-638 | 4,200 psi |

| Dureza | ASTM D-2240 (Shore D) | 85 |

| Resistencia a la abrasión | ASTM D-4060 (CS-17 Wheel) | 30 mg loss / 1000 cycles |

| Resistencia a los impactos | MIL-D-3134 | > 150 in-lbs |

| Linear Expansion | ASTM C-531 | 2 x 10^-5 in/in/°F |

| Water Absorption | ASTM D-570 | 0.04% |

| Contenido de COV | - | 0 g/L |

Ideal Applications for Ure-Crete™ HF

This versatile cementitious urethane flooring system is the trusted choice across diverse industries:

Procesado de alimentos y bebidas: Bottling plants, kitchens, dairies, meat/poultry processing, breweries.

Manufacturing: Automotive plants, chemical processing, general assembly areas.

Warehousing & Distribution: High-traffic aisles, loading docks, automated storage and retrieval system (AS/RS) areas.

Commercial & Institutional: School laboratories, hospital kitchens, commercial laundry facilities.

Anywhere that demands a seamless, durable, and chemically resistant floor that can be installed over concrete.

Professional Installation & Our Support

A superior product requires expert installation. The success of Ure-Crete™ HF depends on meticulous surface preparation and proper application by qualified contractors.

Key Installation Steps:

Substrate Evaluation & Preparation: Concrete must be sound, clean, and dry. Mechanical preparation via shot blasting or diamond grinding to a CSP 3-6 profile is essential. Critical moisture testing (ASTM F-2170) is performed.

Priming & Keyway Detailing: The system is self-priming. Keyways are cut at edges and joints to ensure a monolithic bond and prevent chipping.

Mezcla y aplicación: The three-component system (resin, hardener, aggregate) is power-mixed to a homogeneous consistency and applied via screed box and steel trowel at the specified thickness.

Finishing & Curing: The material is finished with steel trowels to a smooth, dense surface and allowed to cure fully before subjecting to service.

Our Technical Partnership: We don’t just sell products; we provide solutions. Our team offers:

Pre-Installation Consultation: Site evaluation and specification guidance.

Detailed Technical Data: Access to comprehensive SDS, guides, and specifications.

On-Site Support: Available to assist your contractors during critical project phases.

Preguntas más frecuentes (FAQ)

Q: What is the difference between Ure-Crete™ HF cementitious urethane and standard epoxy flooring?

A: While both are resin-based systems, Ure-Crete™ HF is a cementitious urethane mortar that combines polyurethane resins with cementitious aggregates. This gives it key advantages over epoxy: superior flexibility and thermal shock resistance (its expansion rate matches concrete, preventing cracking), higher abrasion and chemical resistance, and better performance in wet or thermally cycling environments (like freezers or areas with hot washdowns). Epoxy can become brittle over time under thermal stress.

Q: How thick is Ure-Crete™ HF applied, and can it be used to repair cracks or slope floors?

A: Ure-Crete™ HF is a trowel-applied mortar system typically installed at 1/4 inch (6 mm) to 3/8 inch (9.5 mm) thick. Yes, it is excellent for repair and contouring. It can directly overlay cracks up to a certain width and, when blended with additional aggregate, can be used to create slopes to drains or form containment berms in a single application, making it a versatile solution for both resurfacing and corrective work.

Q: What is the required surface preparation for installing Ure-Crete™ HF?

A: Proper installation starts with meticulous surface prep. The concrete substrate must be clean, sound, and dry. This typically involves mechanical profiling via shot blasting or diamond grinding to achieve a CSP 3-6 profile. Crucially, moisture vapor emission must be tested (e.g., ≤99% relative humidity per ASTM F-2170). All edges, joints, and penetrations also require a “keyway” (a small groove) to be cut to ensure a monolithic bond and prevent chipping.

Q: How long does installation take, and when can the floor be put back into service?

A: The installation timeline depends on area size and conditions. After surface prep, the material is mixed and troweled in sections. Cure times are temperature-dependent: for light foot traffic, a minimum of 8 hours at 75°F (24°C) is required. For full service with heavy loads and equipment, a minimum of 24 hours at 75°F is recommended. At 50°F (10°C), cure times extend accordingly.

Q: Is Ure-Crete™ HF slip-resistant and suitable for food processing areas?

A: Yes. The finish can be tailored for safety. A standard trowel finish provides good traction, and for enhanced slip resistance, aluminum oxide or other aggregates can be broadcast into the surface during application. The system creates a seamless, non-porous, and chemically resistant surface that is easily cleaned and sanitized, making it an excellent choice for food processing areas and compliant with relevant hygiene standards.

Q: What is the cost range for a Ure-Crete™ HF flooring system?

A: The total project cost depends on several variables: the condition of the existing substrate (extent of repair needed), the total square footage, the specified thickness, any custom coloring or special safety textures, and geographic location. As a premium, high-performance system, it represents a long-term investment. For an accurate budget, we recommend a site evaluation and formal quote. It is designed to offer a lower total cost of ownership through exceptional durability and reduced maintenance.

Trust Built on Proven Performance

Leading companies in demanding sectors trust high-performance resinous flooring for their critical facilities. While specific client names are confidential, our systems are specified for:

Major food production and packaging facilities.

Automotive component manufacturing plants.

International logistics and distribution hubs.

Our formulations are developed to meet relevant industry standards for hygiene, slip resistance, and durability. We invest in continuous R&D to ensure our products remain at the forefront of flooring technology.

KAIDA PAINT for Your Flooring Solution

For over 15 years, KAIDA PAINT has been at the forefront of developing innovative protective coating solutions for industry. We understand that your facility’s floors, walls, and structures are capital assets that require intelligent protection to maximize lifespan, safety, and operational efficiency. Unlike generic suppliers, we focus on high-performance polymer systems—like our flagship Ure-Crete™ HF cementitious urethane—engineered to meet the specific, often extreme, challenges faced by modern companies.

Our advantage is a blend of deep chemical formulation expertise and practical application knowledge. We work directly with facility owners, specifying engineers, and expert contractors to ensure not only that the right products are selected but also that they are installed correctly for long-term performance. We provide comprehensive support, from free project evaluations and detailed specifications to on-site technical assistance.

Why choose KAIDA PAINT for your next industrial flooring project?

Proven Formulations: Products like Ure-Crete™ HF are battle-tested in real-world environments.

Technical Collaboration: We act as an extension of your team, offering unbiased advice.

Quality Assurance: Consistent, high-quality materials manufactured under strict controls.

Total Cost of Ownership Focus: We provide solutions that reduce long-term maintenance and downtime cost.

Ready to specify a floor that lasts? Contact a KAIDA PAINT technical representative today. Let us analyze your needs, provide samples, and deliver a solution that performs.