Descripción

ResuShield™ Grind and Seal is a 100% solids epoxy concrete floor sealing system designed to enhance and protect prepared concrete substrates. By combining a clear epoxy primer, optional body coat, and a durable urethane topcoat, this system delivers exceptional UV resistance, wear protection, and chemical resistance. It is ideal for commercial, industrial, and institutional settings where a clean, natural concrete aesthetic is desired.

User Pain Points & Common Flooring Problems

Industrial and commercial floors face daily challenges: cracks, dusting, chemical spills, heavy foot and vehicle traffic, moisture issues, and hygiene concerns. For example, food processing plants require acid-resistant, easy-to-clean surfaces; warehouses need high-impact and abrasion-resistant flooring; parking garages demand UV-stable, slip-resistant finishes. Traditional coatings often fail under these stresses, leading to costly repairs and downtime.

Product Solution & Key Features

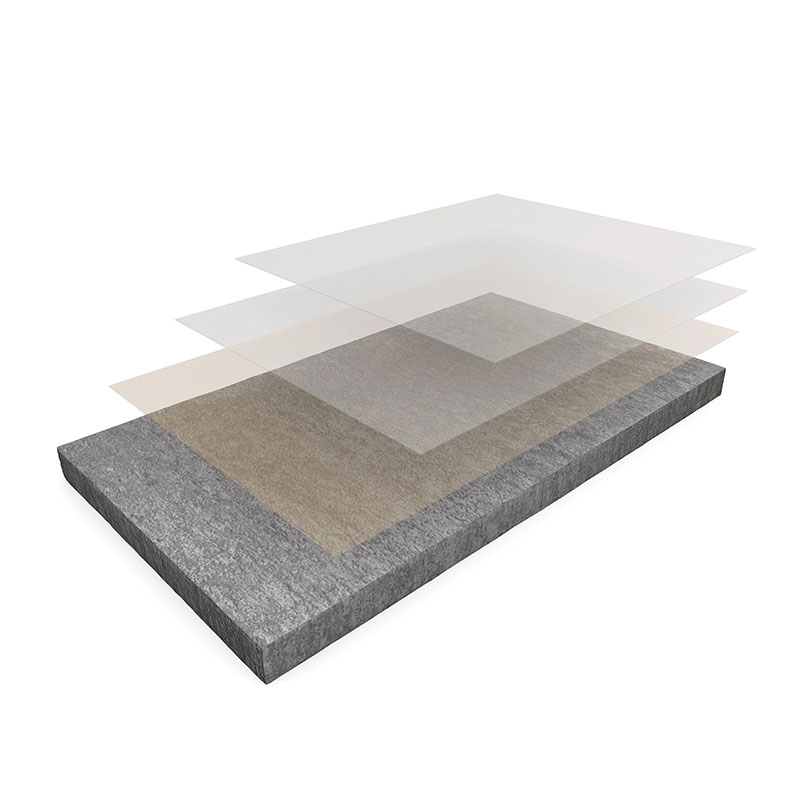

ResuShield™ Grind and Seal addresses these issues with a robust, multi-layer system:

Mechanical Performance:

Abrasion Resistance: ASTM D4060 tested—loss of only 4-12 mg (CS-17 wheel, 1000g load).

Impact Resistance: Withstands heavy loads without cracking or delamination.

Tensile Strength: 2,100 psi (ASTM D2370).

Resistencia química:

Resists oils, acids, alkalis, and common industrial chemicals.

Ideal for facilities requiring frequent cleaning and sanitization.

Physical Properties:

Seamless, dust-proof, and easy to clean.

Slip-resistant options available (static coefficient >0.6).

UV-resistant topcoat reduces yellowing and discoloration.

Aesthetic Flexibility:

Clear finish showcases the natural concrete look.

Optional satin or gloss sheen.

Customizable with grit additives for enhanced traction.

Environmental & Safety Compliance:

0 g/L VOC, low odor—safe for occupied spaces.

Meets USDA, FDA, and California Section 01350 indoor air quality standards.

Especificaciones técnicas

| Propiedad | Método de ensayo | Valor |

|---|---|---|

| Solids Content | – | 100% (primer/body), 95% (topcoat) |

| COV | – | 0 g/L |

| Dureza | ASTM D3363 | >4H |

| Adhesión | ASTM D7234 | Substrate Failure |

| Brillo (60°) | ASTM D523 | Gloss: 75±10, Satin: 50±10 |

| Tiempo de curado completo | – | 5-7 days at 70°F |

| Return to Service | – | 24 horas |

Aplicaciones

ResuShield™ Grind and Seal is suitable for a wide range of environments:

Offices & Retail Spaces

Warehouses & Storage Facilities

Plantas de procesamiento de alimentos y bebidas

Parking Garages & Commercial Corridors

Healthcare & Educational Institutions

Manufacturing & Logistics Centers

Installation Process & Professional Support

Proper installation ensures long-term performance. Key steps include:

Preparación de la superficie:

Shot blast or grind to CSP 2 profile.

Remove contaminants, repair cracks, and ensure a dry, dust-free substrate.

Aplicación de imprimación:

Mix ResuShield™ Glaze resin and hardener (2:1 ratio).

Apply at 300 sq ft/gal for a 5-mil dry film thickness.

Body Coat (Opcional):

Follow primer process for added thickness and durability.

Aplicación de la capa final:

Use ResuShield™ AT urethane topcoat for UV and chemical resistance.

Apply via roller at 550-750 sq ft/kit, depending on finish.

Curing:

Allow 8-12 hours for initial cure; full chemical resistance in 5-7 days.

We recommend working with certified contractors and utilizing our technical support for optimal results.

Preguntas más frecuentes (FAQ)

Q: How does ResuShield™ Grind and Seal compare to standard epoxy coatings?

A: Unlike traditional epoxy, ResuShield™ features a UV-resistant urethane topcoat that reduces yellowing and offers superior chemical and abrasion resistance.

Q: What is the typical cost per square foot for installation?

A: Cost varies based on substrate condition, system thickness, and project size. Contact us for a detailed quote.

Q: Can this system be applied in high-moisture environments?

A: Yes, but proper moisture testing (ASTM F2170) and mitigation systems are required for slabs with high relative humidity (>80%).

Q: How long does installation take?

A: For a standard 10,000 sq ft area, surface prep may take 1-2 days, with coating application and curing completed within 3-4 days.

Case Studies & Certifications

Our system has been installed in numerous industrial and commercial facilities worldwide, providing long-lasting performance in demanding environments. ResuShield™ complies with major industry standards and is backed by KAIDA PAINT’ technical expertise and warranty.

About KAIDA PAINT

KAIDA PAINT is a leading manufacturer and solution provider for high-performance industrial coatings. With decades of experience, we offer tailored flooring systems, professional installation guidance, and ongoing technical support. Our team works directly with contractors, facility managers, and design professionals to deliver durable, cost-effective flooring solutions.

Ready to upgrade your flooring? Contact KAIDA PAINT today for a free consultation, sample testing, and project quote. Let us help you choose the best coating system for your needs.