Beskrivning

Produktöversikt

CrylForte™ is a professional-grade, seamless acrylic flooring system engineered for demanding industrial and commercial environments. This fast-curing, methyl methacrylate (MMA)-based system incorporates a broadcast quartz aggregate to create a highly durable, slip-resistant surface. It achieves full operational strength in as little as one hour, offering an exceptional combination of rapid return-to-service and long-term performance for facilities where downtime is costly.

Core Benefits:

Extreme Durability & Strength: Withstands heavy foot and vehicular traffic, impact from dropped tools, and constant mechanical wear.

Rapid Cure & Installation: Each coat cures in 45-60 minutes, allowing for a complete installation and a return to full service often within a day.

Broad Temperature Tolerance: Can be installed in temperatures as low as 0°F (-18°C), making it ideal for cold environments like walk-in freezers, coolers, and loading docks.

Överlägsen kemisk resistens: The system’s standard topcoat provides proven resistance to a wide range of chemicals, oils, and sanitizers common in industrial settings.

100% Reactive, Low-VOC Formula: Contains less than 100 g/L VOC, contributing to better indoor air quality and compliance with stringent standards like CA Section 01350.

Target Customer Pain Points & Application Scenarios

Industrial and commercial facility managers, contractors, and specifiers face constant challenges with their floors. Traditional options like bare concrete, epoxy, or vinyl tile often fail under pressure, leading to operational headaches and expensive repairs.

Common Pain Points:

Cracking & Damage: Concrete floors crack and spall under heavy loads or impact, creating trip hazards and requiring frequent patching.

Dusting & Degradation: Untreated or poorly sealed concrete creates constant dust, contaminating products and damaging sensitive equipment.

Chemical Attack: Floors in labs, bottling plants, and food processing areas are eroded by acids, alkalis, solvents, and cleaning agents.

Moisture & Mold Issues: Moisture vapor transmission through slabs can cause coating delamination, adhesive failure, and microbial growth.

Lengthy Downtime: Many flooring systems require days or even weeks to fully cure, disrupting business operations and revenue.

Slippery Surfaces: Wet or oily conditions create unsafe work environments, increasing the risk of accidents.

CrylForte™ is the engineered solution for:

Anläggningar för mat och dryck: Requires USDA/FDA-compliant, easy-to-clean, and chemically resistant floors for bottling areas and processing plants.

Pharmaceutical & Laboratory Spaces: Demands seamless, non-porous surfaces that can be sanitized thoroughly and resist chemical spills.

Logistics & Warehousing: Needs ultra-durable flooring to withstand constant forklift traffic, pallet impacts, and heavy loads in traffic aisles.

Cold Storage & Freezer Environments: Requires a system that can be applied and perform reliably in sub-freezing temperatures without becoming brittle.

Manufacturing & Automotive Plants: Seeks high-strength flooring resistant to oils, coolants, and constant abrasion from machinery and foot traffic.

Product Solution & Detailed Features

The CrylForte™ system is more than just a floor paint or coating; it’s a complete, integrated solution designed from the ground up for industrial performance.

1. Unmatched Mechanical Performance:

High Strength: The MMA resin and quartz matrix delivers a high tensile strength, creating a floor that can stand up to extreme loads.

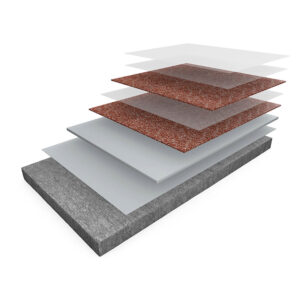

Slip-Resistant Safety: The broadcast quartz aggregate provides a permanent, textured surface for superior traction, even when wet or oily, enhancing slip resistance.

Seamless & Durable: The monolithic finish has no grout lines or seams to harbor bacteria, dirt, or moisture, making it exceptionally easy to clean.

2. Proven Chemical & Environmental Resistance:

Broad Chemical Resistance: Resists a wide array of chemicals typical in industrial settings. Specific chemical resistance should be verified for unique combinations.

Termisk stabilitet: Performs consistently across a wide temperature range, from freezer applications to ambient factory floors.

Moisture Tolerance: When applied over a properly prepared substrate with acceptable moisture levels, it provides an excellent shield against vapor transmission.

3. Efficient Application & Sustainability:

Fast-Cure Technology: The rapid cure minimizes facility downtime, allowing businesses to resume operations quickly.

Low-VOC Compliance: Meets strict indoor air quality requirements, making it suitable for occupied facilities during installation.

Long-Lasting Finish: Eliminates the need for frequent waxing or sealing, reducing long-term maintenance cost.

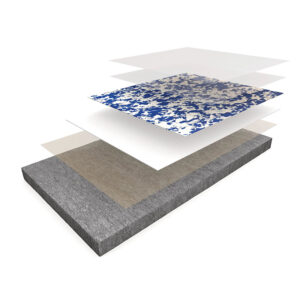

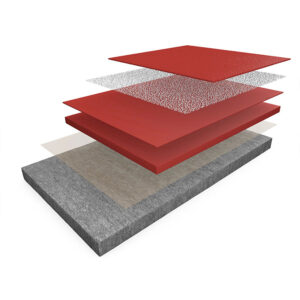

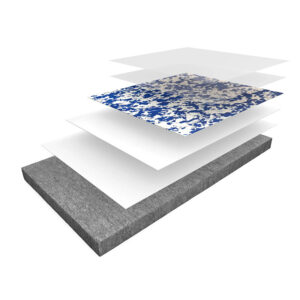

4. Aesthetic & Functional Flexibility:

Färg- och designalternativ: Available in a range of standard and custom colors to meet commercial and industrial design needs, from gray to white and beyond.

Gloss Level: Can be specified to achieve the desired gloss or low-gloss finish for safety and aesthetics.

Thickness Options: A nominal 1/8″ thickness is standard, with options for a thicker 3/16″ system (using Q-Rok aggregate) for areas expecting severe impact.

Technical Specifications & Authority Data

The performance of the CrylForte™ system is backed by measurable data and compliance with industry standards.

| Component | Fastighet | Testmetod | Value / Performance |

|---|---|---|---|

| Primer (P-101) | Draghållfasthet | ASTM D 638 | 3,550 psi |

| VOC-innehåll | < 100 g/L | ||

| Pot Life @ 68°F | 10-20 minutes | ||

| Bond Coat (G-201) | Draghållfasthet | ASTM D 638 | 2,175 psi |

| Water Absorption | ASTM D 570 | 0.04% | |

| Topcoat (T-301) | Draghållfasthet | ASTM D 638 | 3,550 psi |

| Water Vapor Transmission | DIN 53122 | 0.9 g/cm·hr·mm Hg x 10^-9^ | |

| Overall System | Heltid Cure Time | ~1 hour per coat | |

| Recommended Service Temp | -40°F to 212°F (-40°C to 100°C) | ||

| Halkmotstånd | Created by quartz broadcast | ||

| Compliance | Meets USDA, FDA, CA Section 01350 |

Primary Application Fields

CrylForte™ is the best choice for contractors and companies across diverse sectors:

Bearbetning av livsmedel och drycker: Bottling plants, meat packing, dairy facilities, breweries.

Pharmaceutical & Biotechnology: Cleanrooms, laboratories, packaging areas.

Light & Heavy Manufacturing: Automotive plants, metal fabrication, electronic assembly.

Logistics & Distribution: Warehouse aisles, loading docks, distribution centers.

Commercial & Institutional: School kitchens, hospital corridors, public utility plants.

Cold Storage: Walk-in freezers, refrigerated warehouses, chillers.

Installation Process & Technical Support

A successful installation is critical to performance. The CrylForte™ process is methodical and requires professional execution.

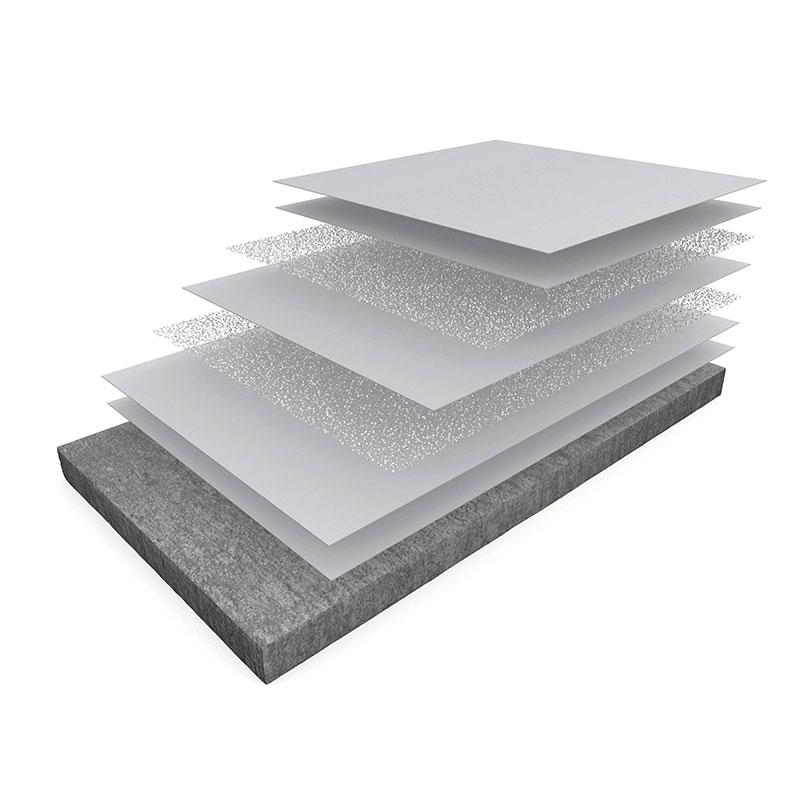

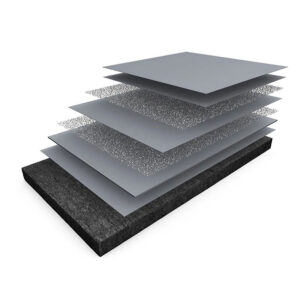

Key Installation Steps:

Substrate Preparation & Evaluation: Concrete must be clean, sound, and dry. Mechanical preparation via shot blasting to a CSP 3-4 profile is required. Critical moisture and bond tests are performed.

Primer Applicering: CrylForte P-101 primer is rolled onto the prepared concrete to ensure optimal adhesion.

Body Coat & Aggregate Broadcast: Two coats of pigmented CrylForte G-201 resin are applied. Each is immediately broadcast with flintshot quartz sand to fill and reinforce the system.

Applicering av topplack: Two final coats of CrylForte T-301 are applied, sealing in the aggregate and providing the final wear surface and color.

Why Professional Specification Matters:

Selecting the right flooring system is complex. Our team provides unparalleled technical service, from pre-installation conferences to on-site support, ensuring your project is specified and executed correctly for long-term success.

Vanliga frågor och svar (FAQ)

Q: How does CrylForte™ compare to epoxy flooring?

A: While both are resinous flooring systems, CrylForte™ (MMA) cures much faster than epoxy, can be installed at lower temperatures, and typically offers better resistance to thermal shock and UV yellowing. Epoxy may have higher ultimate chemical resistance in some specific formulations, but for speed and cold-weather application, CrylForte™ is superior.

Q: How long does the CrylForte™ system last?

A: With proper installation and maintenance, a CrylForte™ floor can last for decades in heavy industrial settings. Its longevity is a key factor in its overall value, reducing the total cost of ownership compared to less durable options like paint or thin coatings.

Q: Can CrylForte™ be applied over an existing floor?

A: It can be applied over sound, properly prepared existing substrates like concrete, metal, and some tile floors. A thorough evaluation by a professional is necessary to determine if the existing base is suitable.

F: Vilket underhåll krävs?

A: Maintenance is simple. Regular sweeping and occasional damp mopping with neutral cleaners are usually sufficient. Avoid harsh chemicals or strippers. Its seamless nature means there’s no grout to clean or repair.

Trust & Proven Performance

CrylaflForte™, backed by Sherwin-Williams High Performance Flooring, is specified by leading manufacturers and contractors worldwide for critical environments. The system’s compliance with USDA, FDA, and stringent indoor air quality standards underscores its reliability for sensitive applications. It’s not just a product; it’s a specification for performance and peace of mind.

KAIDA PAINT Brand

At KAIDA PAINT, we are more than just a supply company; we are your comprehensive industrial flooring solutions partner. As a professional manufacturer and service provider, we combine high-quality products like advanced resinous coatings with deep technical expertise and project support. We understand that the right flooring system is critical to your facility’s safety, efficiency, and bottom line.

Our company works directly with business owners, facility managers, and contractors to assess needs, recommend the optimal solution—whether it’s the fast-cure CrylForte™ system, a high-chemical-resistant epoxy, or a durable polyurethane—and support a flawless installation. We provide everything from kits for smaller DIY projects to full-scale commercial supply and specification support.

Ready to upgrade your industrial floor? Contact KAIDA PAINT today for a consultation, quote, or to get technical data sheets. Let our team help you design and install a floor that stands up to your challenges.

KAIDA PAINT High-Performance Flooring Solutions

Navigating the complex world of industrial flooring requires a partner with both proven products and deep expertise. KAIDA PAINT stands as a leading manufacturer and solution provider dedicated to protecting your assets and enhancing your operational efficiency. We don’t just supply paint; we deliver engineered coating systems backed by rigorous R&D, quality control, and unwavering technical support.

Our partnership with industry leaders allows us to offer cutting-edge technology like the CrylForte™ system. We understand the unique challenges faced by contractors and facility managers—from preparation and moisture issues to selecting the right system for chemical exposure or impact resistance. Our team works alongside you, offering specification guidance, detailed application protocols, and on-site support to ensure every installation is a success.

Whether your project is a residential garage, a sprawling warehouse, or a sensitive pharmaceutical cleanroom, KAIDA PAINT has the best solution. We offer a full portfolio, including epoxy, polyurethane, and acrylic systems, in a wide range of colors and finishes.

Stop compromising on your floor’s performance. Contact KAIDA PAINT today for a free project assessment. Let us show you how our products and service can provide a long-lasting, high-performance flooring solution tailored to your needs and budget. Get in touch now to request a quote, review technical data, or schedule a consultation with our experts.