Beskrivning

Produktöversikt

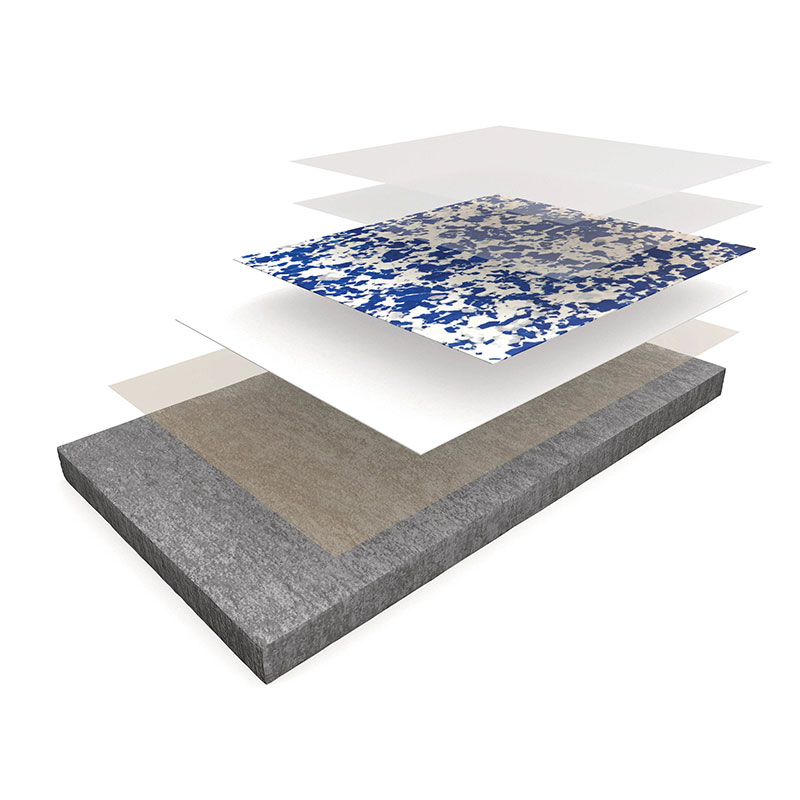

CrylForte™ Deco Flake SL is a seamless, 100% reactive acrylic flooring system designed for demanding commercial and industrial environments. Through its advanced methyl methacrylate (MMA) resin technology, it forms a rapid-curing, high-strength overlay with a terrazzo-like aesthetic. This system offers exceptional durability, chemical resistance, and a fast return-to-service time. CrylForte™ Deco Flake SL delivers a high-performance, low-maintenance solution for facilities such as warehouses, manufacturing plants, laboratories, and food processing areas.

User Pain Points & Scenario Analysis

Industrial and commercial floors face constant abuse that leads to costly downtime, safety hazards, and frequent repairs. Common issues include:

Cracking & Spalling: Heavy traffic and impact from forklifts and dropped equipment can crack standard concrete and epoxy floors.

Dusting & Degradation: Unsealed floors create dust, contaminating products and air quality.

Chemical Attack: Spills from oils, solvents, acids, and cleaning chemicals can stain, soften, and degrade many floor coatings.

Wear & Tear: Constant abrasion from foot and wheel traffic wears down the finish, leading to a worn-out, unprofessional look.

Hygiene Concerns: In food, pharmaceutical, and lab settings, porous floors harbor bacteria and are difficult to clean and sanitize.

Moisture Problems: Moisture vapor transmission from subfloors can cause blistering and adhesive failure in many flooring systems.

Specific scenarios demanding CrylForte™ Deco Flake SL:

Food & Beverage Plants: Requires USDA/FDA-compliant, seamless floors that resist chemical sanitizers, acids, fats, and hot water pressure washing.

Logistics Warehouses: Needs ultra-high abrasion and impact resistance to withstand heavy pallet jacks, forklifts, and continuous traffic without showing wear.

Parking Garages: Demands a coating that can handle thermal cycling, de-icing salts, oil, and tire abrasion while maintaining an attractive finish.

Laboratories & Cleanrooms: Imperative to have a non-porous, monolithic surface that won’t support microbial growth and can be easily cleaned and disinfected.

Product Solution & Detailed Features

CrylForte™ Deco Flake SL directly addresses these challenges with its superior performance profile.

Oöverträffad hållbarhet:

Abrasion Resistance: With a Taber Abrasion loss of only 29mg (CS17 wheel, 1000g, 1000 cycles), it far outlasts epoxy and urethane systems.

Impact Resistance: Passes MIL-D-3134 impact tests, resisting damage from dropped tools and equipment.

High Strength: Compressive strength exceeds 8,000 psi and tensile strength is 2,000 psi.

Överlägsen kemisk resistens:

The non-porous, seamless surface resists a wide range of chemicals including oils, greases, dilute acids, alkalis, and many solvents, making it easy to clean and maintain.

Exceptional Physical Properties:

Fast Cure: Each coat cures tack-free in 45-60 minutes at 68°F, allowing a 1-hour return to light service and rapid project completion.

Sömlös och hygienisk: No grout lines or seams to trap dirt, moisture, or bacteria.

Halkmotstånd: Can be formulated with additives to achieve a high coefficient of friction (>0.6 per ASTM D2047), meeting slip-resistant requirements for safety.

Termisk stabilitet: Withstands temperatures from 0°F for installation up to 140°F continuous service.

100% Solids & Low VOC: Contains no solvents or water, minimizing odor and meeting strict indoor air quality standards like CA Section 01350.

Aesthetic Versatility & Customization:

Available with Micro or Macro decorative color flakes in unlimited standard and custom blends.

Final finish can be smooth or textured for added grip.

Provides a high-gloss, attractive terrazzo appearance that enhances facility aesthetics.

Ease of Installation & Performance:

Self-Leveling formula ensures a smooth, uniform surface, ideal for correcting minor substrate imperfections.

Can be installed over properly prepared concrete, even in basement applications with appropriate moisture testing.

Technical Specifications & Authoritative Data

| Fastighet | Testmetod | Value / Performance |

|---|---|---|

| System Type | – | 100% Reactive MMA Acrylic |

| Typical Thickness | – | 3/16 inch (4.75 mm) nominal |

| Tryckhållfasthet | ASTM C-109 | 8,300 psi |

| Draghållfasthet | ASTM D-638 | 2,000 psi |

| Flexural Strength | ASTM D-790 | 3 700 psi |

| Motståndskraft mot nötning | ASTM D-4060 (CS17) | 29 mg loss |

| Hårdhet | ASTM D-2240 (Shore D) | 88-92 |

| Water Absorption | ASTM D-570 | 0.04% |

| Bond Strength to Concrete | – | >400 psi (substrate failure) |

| Pot Life @ 68°F | – | 10-20 minutes |

| Cure Time @ 68°F | – | 45-60 minutes per coat |

| VOC-innehåll | – | < 100 g/L |

| Spridning av flamman | ASTM E-84 | Klass A |

Tillämpningsområden

CrylForte™ Deco Flake SL is the preferred choice across diverse sectors:

Industri och tillverkning: Automotive plants, warehouses, bottling facilities, heavy machinery areas.

Kommersiellt och detaljhandel: Supermarkets, shopping malls, restrooms, lobbies, kitchens.

Institutionell: Schools, hospitals, airports, parking structures.

Food & Pharma: Processing areas, walk-in coolers, freezers, packaging rooms, laboratories.

Specialized: Animal research facilities, cleanrooms, chemical processing areas.

Installation Process & Technical Support

A successful installation is a partnership. The key steps involve:

Förberedelse av ytan: Critical step. Concrete is shot-blasted to a CSP 3-4 profile to ensure a clean, sound, and profiled substrate. Moisture and bond tests are performed.

Priming: CrylForte™ P-101 primer is applied to seal the substrate and promote superior adhesion.

Basecoat/Flake Broadcast: The self-leveling CrylForte™ G-201 basecoat is poured, raked to thickness, and immediately broadcast with decorative flakes.

Sealing & Topcoating: Excess flakes are removed after cure. Two coats of clear CrylForte™ T-301/T-303 topcoat are applied for protection and gloss.

Our Commitment: KAIDA PAINT provides more than just products. We offer comprehensive support including:

Pre-installation Consultation: Site evaluation and specification guidance.

Technical Data & SDS: All necessary documentation for contractors.

On-Site Support: Available for complex projects.

Quality Assurance: Guidance on best practices for prep, application, and cure.

Vanliga frågor och svar (FAQ)

Social Proof & Trust Building

Proven in Demanding Environments: Trusted by Fortune 500 manufacturers, global logistics companies, and leading food processing plants.

Compliance & Certification: Meets or exceeds relevant standards for USDA, FDA, and CA Section 01350 indoor air quality.

Industry Recognition: A flagship product of Sherwin-Williams High Performance Flooring, a global leader in industrial coatings.

KAIDA PAINT Brand Introduction

Your Trusted Partner in Advanced Flooring Solutions

In the complex world of industrial and commercial construction, the right flooring is foundational to safety, efficiency, and longevity. KAIDA PAINT stands as a premier provider, bridging the gap between cutting-edge coating technology and real-world application. We specialize in supplying and supporting high-performance systems like the CrylForte™ Deco Flake SL for the most challenging environments.

Our expertise goes beyond distribution. We act as your technical partner, offering:

Unbiased Consultation: We analyze your traffic, chemical exposure, substrate, and budget to recommend the optimal system—whether MMA, epoxy, polyurethane, or a hybrid.

Quality Assurance: We partner with world-leading manufacturers to ensure every product meets the highest standards for performance and consistency.

Project Success Focus: We support contractors with detailed specifications, SDS, and technical back-up, and assist facility managers with lifecycle cost analysis and maintenance planning.

In a market filled with options, KAIDA PAINT delivers clarity, quality, and confidence. Let us help you invest in a floor that protects your assets and enhances your operations for years to come. Contact our team of specialists today for a consultation.

Stop compromising on your floor’s performance, safety, and appearance. Request a free project consultation, a technical data sheet, or a sample today. Let our experts analyze your facility’s requirements and provide a solution that will stand the test of time.

Contact KAIDA PAINT now to get started.