Pelapis Lantai Poliuretan JINYU PAINT® JINYU PAINT

PRODUK LANTAI POLIURETAN JINYU PAINT® PRODUK LANTAI POLIURETAN

Menampilkan 1–16 dari 23 hasil

-

Cat Lantai Beton Poliuretan Anti Selip Self-leveling Anti Korosif Penahan Beban

Baca selengkapnya -

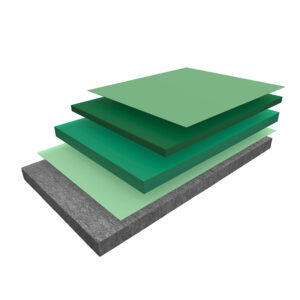

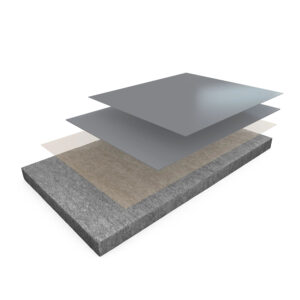

FlexTop™ Comfort SL Urethane Flooring System

Baca selengkapnya -

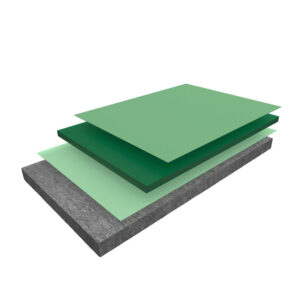

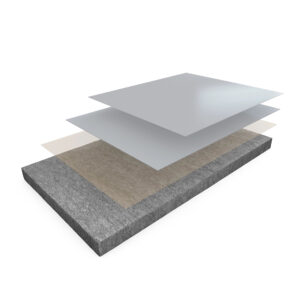

FlexTop™ RXC Urethane Flooring System

Baca selengkapnya -

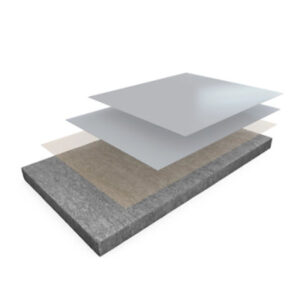

FlexTop™ SL Urethane Flooring System

Baca selengkapnya -

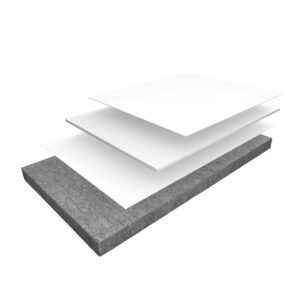

Sistem Lantai Screed PU yang dapat meratakan sendiri JINYU PAINT® MF

Baca selengkapnya -

JINYU® DT Lapisan Atas PU Tahan Abrasi

Baca selengkapnya -

Pelapis Lantai Uretan Tugas Berat JINYU® HD

Baca selengkapnya -

JINYU® MF 4-6mm Cat Poliuretan Untuk Lantai Beton

Baca selengkapnya -

JINYU® SL Pelapis Lantai Uretan Self-Leveling Self-Leveling Semi-Gloss Finish

Baca selengkapnya -

JINYU® UD 9-12mm Cat Lantai Beton Poliuretan Anti Selip Tugas Berat

Baca selengkapnya -

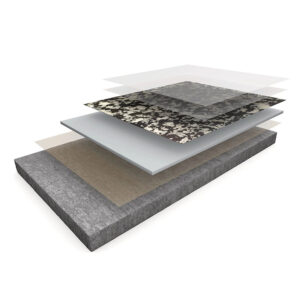

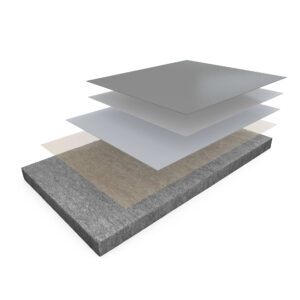

Polypro™ Advanced NMP Performance EV Urethane Flooring System

Baca selengkapnya -

Polypro™ NMP Performance EV Urethane Flooring System

Baca selengkapnya -

Polypro™ Performance HPS Urethane Flooring System

Baca selengkapnya -

Polypro™ Performance HTS Urethane Flooring System

Baca selengkapnya -

Polypro™ XT Topcoat AC Urethane Flooring System

Baca selengkapnya -

Polypro™ XT Topcoat TX Urethane Flooring System

Baca selengkapnya

Keuntungan Pelapis Lantai Poliuretan (Lantai Pu)

Pelapis lantai poliuretan (uretan) adalah solusi lantai berkinerja tinggi yang banyak digunakan dalam aplikasi industri, komersial, dan residensial karena daya tahan, fleksibilitas, dan daya tarik estetika yang unggul.

1. Ketahanan aus yang luar biasa

- Daya rekat tinggi ke berbagai substrat (beton, epoksi, ubin, dll.)

- Kuat secara mekanis-tahan terhadap abrasi, benturan, dan beban berat

- Performa yang teruji: Tahan jatuhnya bola baja 500g dari ketinggian 100cm tanpa retak atau terkelupas

- Ketahanan terhadap bahan kimia & korosi-ideal untuk pabrik, gudang, dan pabrik kimia

2. Penyesuaian yang Sangat Baik (Keserbagunaan)

- Pilihan warna yang luas-dapat disesuaikan untuk menyesuaikan dengan kebutuhan branding atau desain

- Ketebalan yang bisa disesuaikan (lapisan dekoratif tipis atau lapisan kelas industri yang tebal)

- Opsi fungsional: Anti-statis, anti selip, tahan api, konduktif, dll.

3. Kemampuan bernapas (Kontrol Kelembaban)

- Lapisan PU berbasis air memungkinkan transmisi uap-Mencegah penggelembungan & delaminasi

- Menghalangi kelembapan eksternal-ideal untuk lingkungan yang lembab (tanaman pangan, ruang bawah tanah, kolam renang)

4. Instalasi Cepat & Mudah

- Dapat ditipiskan dengan air-aplikasi & pembersihan yang mudah

- Pengeringan cepat: Dapat berjalan kaki dalam 24 jam, dapat menahan beban penuh dalam 7 hari

- Rendah VOC & ramah lingkungan-Sesuai dengan standar bangunan hijau

5. Hasil Akhir yang Estetis & Mulus

- Opsi mengkilap/matte/semi-kilap-meningkatkan daya tarik visual

- Mulus & tidak berpori-Mencegah penumpukan debu (ideal untuk rumah sakit, laboratorium)

- Warna-warna tahan UV-tidak memudar dari waktu ke waktu

6. Perawatan & Perbaikan yang Mudah<

- Permukaan halus-mudah dibersihkan (air & deterjen ringan)

- Dapat diperbaiki-perbaikan yang dilokalisasi tanpa pelapisan ulang penuh

- Tahan noda & bahan kimia-Mengurangi biaya jangka panjang

7. Umur Panjang & Daya Tahan Ekstrim

- Lebih dari 20 tahun masa kerja-lebih tahan lama dari epoksi & beton tradisional

- Tahan -60°C hingga 120°C-sempurna untuk freezer, tanaman pangan, dan penggunaan di luar ruangan

- Memperkuat lantai beton-Mencegah keretakan & debu

Aplikasi Industri Lantai Poliuretan

Epoksi atau Poliuretan?

Lantai poliuretan merupakan alternatif yang lebih unggul daripada epoksi di banyak lingkungan industri yang menuntut, menawarkan fleksibilitas yang lebih baik, stabilitas UV yang lebih baik, dan ketahanan yang lebih baik terhadap goncangan termal dan abrasi. Sementara lapisan epoksi memberikan daya rekat yang sangat baik dan ketahanan terhadap bahan kimia, poliuretan lebih unggul di lingkungan yang membutuhkan elastisitas dan ketahanan yang lebih besar. Skenario aplikasi utama meliputi:

- Gudang dan Pusat Logistik

Tidak seperti epoksi, poliuretan mempertahankan fleksibilitas di bawah benturan berat, mencegah keretakan dan pengelupasan akibat lalu lintas forklift yang terus menerus. Ketahanan abrasi yang unggul memastikan masa pakai yang lebih lama di area dengan lalu lintas tinggi. - Pabrik Pengolahan Makanan dan Minuman

Poliuretan menawarkan ketahanan guncangan termal yang lebih baik daripada epoksi selama pencucian yang sering dilakukan dengan air panas, sehingga mencegah pelepuhan atau pengelupasan. Bahan ini juga memberikan ketahanan slip yang lebih tinggi dalam kondisi basah. - Fasilitas Farmasi dan Kamar Bersih

Meskipun keduanya menawarkan permukaan yang mulus, poliuretan menunjukkan ketahanan yang lebih baik terhadap paparan bahan kimia berulang kali dan mempertahankan penampilannya tanpa menguning atau rusak di bawah lampu sterilisasi UV. - Fasilitas Otomotif dan Kedirgantaraan

Dibandingkan dengan epoksi, poliuretan menunjukkan ketahanan yang lebih tinggi terhadap bahan bakar jet, cairan hidrolik, dan suhu ekstrem tanpa melunak atau menjadi rapuh. - Pabrik Manufaktur dan Perakitan

Lantai poliuretan mengungguli epoksi di lingkungan dengan variasi suhu yang signifikan karena kemampuan siklus termal yang unggul dan mengurangi sensitivitas terhadap kelembapan selama pemasangan. - Ruang Penyimpanan Dingin dan Ruang Pembeku

Tidak seperti epoksi, yang dapat menjadi rapuh dan retak dalam kondisi di bawah nol, poliuretan mempertahankan fleksibilitas dan ketahanan benturan, memastikan daya tahan di lingkungan yang membeku Lantai poliuretan menggabungkan kekuatan mekanis canggih dengan ketahanan kimia dan lingkungan, menjadikannya pilihan yang lebih tahan lama dan mudah beradaptasi dibandingkan epoksi untuk fasilitas industri modern yang menghadapi kondisi operasional yang dinamis.

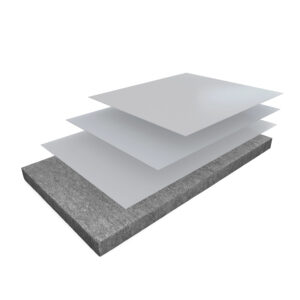

Jenis Umum Pelapis Lantai Poliuretan (PU)

Pelapis lantai poliuretan sangat serbaguna dan dapat disesuaikan untuk berbagai aplikasi. Di bawah ini adalah klasifikasi yang paling umum, bersama dengan fitur dan kegunaan utamanya

① Pelapis Lantai Poliuretan Berbasis Air Mengkilap/Matte

- Jenis: Hasil akhir mengkilap, matte, semi-matte

- Aplikasi: Lantai industri, rumah sakit, gerbong kereta bawah tanah, perpustakaan, dan ruang komersial

- Manfaat: Menghilangkan kebutuhan untuk melakukan waxing/pemolesan sekaligus mempertahankan kilau yang tahan lama

② Lapisan Lantai Poliuretan yang Sangat Tahan Aus

- Fitur: Kepadatan tinggi, kekerasan ekstrem, tahan gores & abrasi

- Aplikasi: Toko mesin, garasi parkir, lapangan olahraga, gudang

- Manfaat: Tahan terhadap alat berat, forklift, dan lalu lintas pejalan kaki yang tinggi

③ Lapisan Lantai Poliuretan yang Cepat Kering

- Jenis: Pengeringan cepat suhu rendah, pengeringan cepat suhu ruangan

- Aplikasi: Konstruksi musim dingin, perbaikan cepat, penandaan garis

- Manfaat: Mengurangi waktu henti, ideal untuk proyek yang sensitif terhadap waktu

④ Pelapis Lantai Poliuretan Dekoratif

- Fitur: Warna-warna cerah, opsi serpihan dekoratif/kuarsa, estetika tinggi

- Aplikasi: Rumah sakit, sekolah, pusat perbelanjaan, kantor

- Manfaat: Memadukan keindahan + daya tahan, mudah dibersihkan

⑤ Pelapis Lantai PU Tahan Suhu Tinggi/Rendah

- Kinerja: Stabil dari -40°C hingga 120°C

- Aplikasi: Pabrik pengolahan makanan, penyimpanan dingin, freezer

- Manfaat: Tidak retak pada suhu ekstrem, sesuai dengan standar FDA

⑥ Lantai Poliuretan Olahraga & Taman Bermain

- Fitur: Penyerapan guncangan yang sangat baik, pengurangan kebisingan, elastisitas

- Aplikasi: Lapangan tenis, lintasan lari, lantai gym

- Manfaat: Mengurangi kelelahan, tahan selip, stabil terhadap sinar UV

⑦ Pelapisan PU Taman & Jalan Kota (Perkerasan Berwarna Anti Selip)

- Fitur: Bebas pelaruttahan selip, mengurangi kebisingan, warna-warna cerah

- Aplikasi: Taman, jalan setapak, plaza, parkir luar ruangan

- Manfaat: Tahan cuaca, retensi warna yang tahan lama

⑧ Lapisan PU Tahan Cuaca untuk Dudukan & Kolam Renang Luar Ruangan

- Fitur: Tahan UV, tahan air, tahan bahan kimia (klorin/air asin)

- Aplikasi: Tempat duduk di stadion, kolam renang, taman air

- Manfaat: Tidak luntur, daya rekat kuat, anti jamur

Pertanyaan yang Sering Diajukan (FAQ):

T1: Apa perbedaan utama antara pelapis lantai epoksi dan poliuretan?

Ini adalah salah satu pertanyaan yang paling banyak dicari di seluruh dunia.

A: Meskipun keduanya merupakan pelapis berkinerja tinggi, keduanya memiliki fungsi utama yang berbeda. Pelapis epoksi terkenal dengan daya rekat, daya tahan, dan kekuatan menahan beban yang luar biasa, menjadikannya lapisan dasar yang ideal. Lapisan poliuretan dihargai karena stabilitas UV yang unggul, ketahanan terhadap bahan kimia, dan ketahanan terhadap abrasi. Lapisan ini juga lebih fleksibel dan memberikan hasil akhir yang lebih halus dan sering kali lebih mengkilap. Sistem terbaik sering kali menggabungkan keduanya: lapisan dasar epoksi untuk kekuatan dan lapisan atas poliuretan untuk perlindungan dan estetika.

T2: Apakah lantai poliuretan tahan terhadap bahan kimia dan noda?

Istilah pencarian: "pelapis lantai tahan bahan kimia," "lantai tahan asam."

A: Ya, ketahanan yang sangat baik adalah alasan utama popularitasnya. Lapisan poliuretan membentuk permukaan yang tidak berpori dan mulus yang sangat tahan terhadap berbagai macam bahan kimia, termasuk minyak, gemuk, bahan bakar, pelarut, dan banyak asam dan basa. Hal ini menjadikannya pilihan utama untuk pabrik makanan dan minuman, garasi otomotif, laboratorium, dan fasilitas farmasi di mana tumpahan sering terjadi.

T3: Apakah lapisan poliuretan akan menguning atau memudar di bawah sinar matahari langsung?

Istilah pencarian: "Lantai garasi tahan UV," "lapisan lantai yang menguning."

A: Tidak seperti epoksi standar, yang dapat mengapur dan menguning di bawah paparan sinar UV, pelapis poliuretan alifatik diformulasikan secara khusus dengan stabilitas UV yang unggul. Lapisan ini dirancang untuk mempertahankan warna dan kilapnya selama bertahun-tahun, bahkan di bawah sinar matahari langsung. Hal ini membuatnya sempurna untuk hanggar pesawat, gudang dengan lampu langit-langit, dan teras atau balkon luar ruangan.

T4: Berapa lama lapisan lantai poliuretan dapat bertahan?

Istilah pencarian: "umur lantai poliuretan," "berapa lama pelapisan lantai garasi bertahan."

A: Masa pakai sangat bergantung pada persiapan permukaan, kualitas pemasangan, dan tingkat lalu lintas. Lapisan atas poliuretan yang diaplikasikan secara profesional di atas sistem epoksi dapat bertahan 10-20 tahun di lingkungan industri atau komersial. Di area dengan lalu lintas tinggi seperti gudang, mungkin diperlukan lapisan penyegaran setiap 5-10 tahun. Perawatan yang tepat sangat penting untuk memaksimalkan masa pakainya.

T5: Apakah lantai poliuretan licin? Apakah lantai ini tahan selip?

Istilah pencarian: "lantai garasi anti selip," "lantai industri tahan selip."

A: Lapisan poliuretan mengkilap standar dapat menjadi licin saat basah. Namun, aditif anti selip (seperti pasir polimer atau pasir kuarsa) dapat dengan mudah disebarkan ke dalam lapisan basah untuk menciptakan permukaan yang bertekstur dan tahan selip. Ini adalah fitur keamanan yang sangat penting untuk area seperti dapur komersial, dek kolam renang, dan pabrik.

T6: Dapatkah saya mengaplikasikan lapisan poliuretan sendiri, atau apakah saya memerlukan seorang profesional?

Istilah pencarian: "Kit lantai poliuretan DIY," "pelapis lantai profesional."

A: Meskipun kit DIY tersedia, namun untuk mencapai hasil yang tahan lama dan berkelas profesional sangatlah menantang. Aplikasi yang tepat membutuhkan ** persiapan permukaan yang cermat (sering kali termasuk penggilingan berlian), kontrol kelembaban dan suhu yang ketat, serta teknik pencampuran dan aplikasi yang ahli**. Untuk aplikasi komersial, industri, atau garasi, kami sangat menyarankan untuk menyewa pemasang profesional bersertifikat.

T7: Berapa lama waktu pengeringan dan waktu henti untuk lantai poliuretan?

Istilah pencarian: "waktu pengeringan lapisan lantai", "berapa lama sebelum saya dapat berkendara di lantai garasi".

A: Lapisan poliuretan biasanya kering secara sentuh dalam waktu 4-8 jam. Lalu lintas pejalan kaki ringan biasanya dapat dilakukan dalam 12-24 jam. Namun, pengeringan penuh (mencapai sifat kimia dan mekanik maksimum) dapat memakan waktu 3-7 hari. Umumnya disarankan untuk menunggu setidaknya 72 jam sebelum memindahkan alat berat atau memarkir kendaraan di permukaan. Selalu ikuti panduan khusus dari produsen.

T8: Dapatkah poliuretan diaplikasikan di atas lantai epoksi yang sudah ada?

Istilah pencarian: "pelapisan ulang lantai epoksi lama," "lapisan atas poliuretan."

A: Tentu saja. Ini adalah praktik yang sangat umum dan sangat disarankan untuk meremajakan lantai epoksi yang sudah tua, usang, atau menguning. Epoksi yang ada harus dibersihkan dengan benar, dikikis ringan (misalnya, ditembak atau ditumbuk), dan dihilangkan lemaknya untuk memastikan daya rekat yang kuat untuk lapisan atas poliuretan yang baru.

Q9: What maintenance is required for a polyurethane floor?

Search terms: “how to clean polyurethane floor,” “industrial floor maintenance.”

A: Maintenance is simple. Regular sweeping or dust mopping removes abrasive debris. For cleaning, use a neutral pH cleaner and a soft-bristle brush or auto-scrubber. Avoid harsh acidic or alkaline cleaners, as they can degrade the surface over time despite its high resistance. Immediately wiping up spills is always recommended.

Q10: What types of environments are polyurethane coatings best suited for?

Search terms: “best coating for food factory floor,” “garage floor coating for cold climate.”

A: Due to their combination of properties, polyurethane coatings are the preferred choice for:

- Food & Beverage Processing: USDA and FDA compliant, easy to clean, chemical resistant.

- Automotive & Aerospace: Resistant to hydraulic fluids, jet fuel, and hot tire pick-up.

- Warehouses & Logistics: Withstand heavy foot and forklift traffic without wearing down.

- Commercial & Retail: High-gloss, aesthetic appeal for showrooms and public spaces.

- Outdoors: UV stability for areas exposed to sunlight.

KAIDA JINYU PAINT Urethane Coating Projects

Bagaimana Cat JINYU Unggulan Dibuat?

JINYU® menawarkan berbagai pilihan warna dan kemungkinan penyesuaian. Pakar warna bekerja sama dengan pelanggan untuk menciptakan corak dan hasil akhir yang unik agar sesuai dengan proyek spesifik mereka.

Aplikasi JINYU PAINT® Unggulan

JINYU PAINT® menyediakan rangkaian lengkap pelapis berkinerja tinggi, termasuk pelapis lantai epoksi, pelapis industri, pelapis tahan api, dan pelapis arsitektural untuk dinding interior dan eksterior. Solusi kami dirancang untuk daya tahan, estetika, dan perlindungan di berbagai aplikasi, mulai dari bangunan perumahan dan komersial hingga fasilitas industri dan proyek keselamatan kebakaran. Apakah Anda membutuhkan lantai yang mulus, ketahanan korosi, perlindungan terhadap api, atau pelapis dinding dekoratif, JINYU PAINT® menawarkan pelapis ahli untuk menyempurnakan dan melindungi setiap permukaan.

FAQ TERBARU di JINYU PAINT®

PERTANYAAN YANG SERING DIAJUKAN

- Cara Mencegah Kerusakan Akibat Sengatan Panas pada Lantai Pemrosesan Makanan: Solusi Beton Uretan

- 7 Strategi Pakar untuk Memperpanjang Umur Lantai Poliuretan di Area dengan Lalu Lintas Tinggi

- Cara Memperbaiki Lantai Poliuretan yang Terkelupas atau Terkelupas: Panduan Perbaikan yang Pasti

- Apa saja praktik terbaik untuk memasang lantai poliuretan di ruang bersih farmasi?

- Jenis lantai apa yang paling cocok untuk gudang logistik dengan lalu lintas forklift?

Hubungi Kami

Kontak: Ibu Sabella Wei

Telepon: 86-022-83859963

Whatsapp: 15822925523