Deskripsi

Pengenalan Produk

Sistem lantai KAIDA PAINT JINYU® MF adalah sistem lantai screed poliuretan (PU, uretan) tiga komponen yang mulus dan bebas pelarut. Dibuat melalui pengikatan silang 3 dimensi antara poliuretan dan beton, sistem ini menghasilkan struktur yang kuat yang digunakan secara luas di industri makanan, minuman, dan lingkungan industri yang keras. Sistem lantai industri yang mulus dan bebas pelarut ini menawarkan ketahanan benturan dan keausan yang luar biasa, di samping ketahanan yang luar biasa terhadap korosi kimiawi, panas, dan kelembapan. Sistem ini mempertahankan permukaan yang bersih, higienis, dan mulus, sehingga ideal untuk pabrik makanan dan minuman serta lingkungan yang keras lainnya.

Aplikasi untuk JINYU® MF PU Screed

JINYU® MF adalah lantai yang ideal untuk area lalu lintas tinggi dan lingkungan dengan guncangan termal sedang. Skenario aplikasi utama meliputi:

- Pabrik Makanan & Minuman: Penanganan bahan baku, penyimpanan kering, pengemasan kering, dan area pemrosesan basah (tanpa minyak berlebihan).

- Fasilitas Logistik: Dermaga bongkar muat dan platform bongkar muat.

- Penyimpanan Dingin: Ruang dingin dan fasilitas pembeku.

- Manufaktur Farmasi: Area produksi yang sesuai dengan GMP.

- Silakan berkonsultasi dengan tim solusi KAIDA untuk skenario penggunaan spesifik lainnya dan solusi lantai khusus.

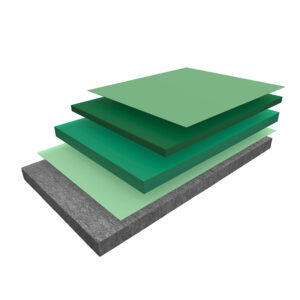

Warna

Tersedia tujuh warna standar (perkiraan):

kuning, bege, gules, biru, hijau, abu-abu muda, abu-abu tua

Warna khusus dapat dipesan berdasarkan MOQ.

Data Teknis Utama & Parameter Kinerja

Data berikut ini diukur dalam kondisi standar laboratorium dan mungkin memiliki sedikit perbedaan dari data aktual di lokasi.

| Item | Parameter |

|---|---|

| Penampilan | Setelah diaduk, campurannya seragam dan bebas dari gumpalan. |

| Kekuatan Rekat Tarik (Standar) | 5,5 N/mm² |

| Kekuatan Rekat Tarik (Rendam dalam air) | 4,5 N/mm² |

| Kekerasan Pantai D | 78.2 |

| Ketahanan benturan (bola baja 1000g) | Tidak ada retakan atau pengelupasan |

| Ketahanan terhadap abrasi (750g/500r) | 0.018g |

| Ketahanan Tekan | 71 MPa |

| Ketahanan Lentur (24 jam) | 13,3 MPa |

| Ketahanan Lentur (7d) | 15,7 MPa |

| Ketahanan terhadap Asam (10% H₂SO₄, 48 jam) | Tidak ada gelembung, Tidak ada pengelupasan, Tidak ada perubahan warna. |

| Ketahanan terhadap Basa (30% NaOH, 48 jam) | Tidak ada gelembung, Tidak ada pengelupasan, Tidak ada perubahan warna. |

| Ketahanan terhadap Garam (3% NaCl, 7D) | Tidak ada gelembung, Tidak ada pengelupasan, Tidak ada perubahan warna. |

| Resistensi Jamur | 0 (tidak ada pertumbuhan jamur, nilai terbaik) |

Standar

JINYU PAINT® MF memenuhi persyaratan yang relevan dari standar GB / T22374 "Bahan Pelapis Lantai".

Pengemasan

JINYU PAINT® MF adalah sistem tiga komponen yang sudah dikemas sebelumnya, dengan satu set berbobot 18,38kg:

Komponen A: 2,68 kg/ember;

Komponen B: 2,5 kg/ember;

Komponen C: 13,2 kg/paket.

Spesifikasi Model

| Item | Deskripsi |

|---|---|

| Sistem | JINYU PAINT MF |

| Selesai | Hasil akhir matte |

| Ketebalan | 4-6 mm |

| Produsen | KAIDA |

Pekerjaan persiapan dan aplikasi sesuai dengan petunjuk produsen.

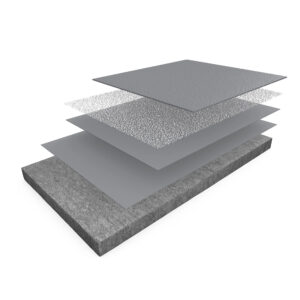

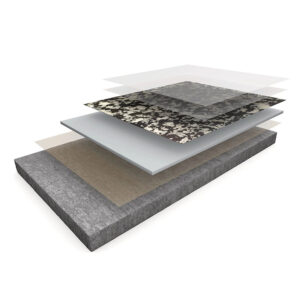

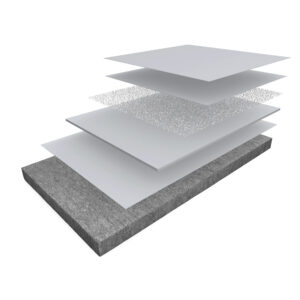

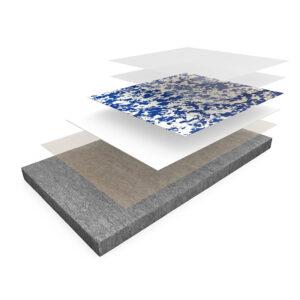

Desain Sistem yang Direkomendasikan untuk Ketebalan 4-6mm

Substrat yang Disiapkan (Beton C25, kekuatan tarik >1,5MPa, beralur dengan benar)

Mantel Gores: Dasar JINYU PAINT MF1 (@ 1,8-2,0 kg/m²) - Sekop diterapkan

Lapisan Permukaan: Lapisan Atas JINYU PAINT MF1 (@ 6,0-6,5 kg/m²) - Bahan Screed PU

Produk yang Termasuk dalam Sistem ini

| Jenis Lapisan | Nama Produk | Jenis Aplikasi / Bahan |

|---|---|---|

| Lapisan dasar | Forincrete MF1 | Trowel Terapkan |

| Mantel atas | Forincrete MF1 | Bahan Screed PU Forincrete MF1 PU |

Pernyataan Metode

Kondisi & Suhu Aplikasi yang Optimal

Suhu aplikasi yang ideal untuk JINYU PAINT® MF adalah antara 15-25 ℃. Tidak disarankan untuk mengaplikasikan MF saat suhu di bawah 5℃, karena akan sangat memengaruhi kemampuan perataannya dan mengakibatkan cacat permukaan. Ketika suhu di bawah 10℃, ini juga dapat secara signifikan memengaruhi kecepatan pengawetan produk. Jika perlu menerapkan MF dalam kondisi suhu melebihi 30℃, diperlukan pekerjaan persiapan yang cukup.

Panduan Persiapan Substrat Beton

Kondisi pondasi yang ideal untuk JINYU PAINT® MF membutuhkan kekuatan dasar beton lebih dari 30MPa. Namun, lantai beton C25 dengan finishing berstandar tinggi masih dapat memenuhi persyaratan konstruksi.

Grinding: JINYU PAINT® MF membutuhkan penggerindaan untuk perawatan dasar dengan pisau berlian yang lebih kasar. Untuk permukaan yang sangat keras seperti lantai yang tahan aus, tetap disarankan untuk menggunakan mesin shot blasting untuk perawatan sandblasting.

Grooving: Beberapa alur harus dipotong dekat ke tepi dinding, dengan kedalaman 6-9mm, lebar 5-8mm. Area tengah harus dipotong pada arah horizontal dan vertikal, dengan jarak sekitar 2 meter.

Untuk permukaan yang sangat keras atau padat, shot blasting adalah metode persiapan yang direkomendasikan untuk memastikan perekatan yang optimal.

Petunjuk Pencampuran untuk Sistem 3 Komponen

Sebelum mencampur, kocok Bagian A dengan baik lalu tuangkan Bagian A dan Bagian B ke dalam ember secara bersamaan. Gunakan mixer berkecepatan rendah untuk mengaduk selama sekitar 5 detik. Direkomendasikan untuk menggunakan mixer listrik dengan kecepatan yang dapat diatur dan torsi tinggi dengan kecepatan rendah. Kemudian secara perlahan tuangkan agregat yang sudah dikantongi Bagian C dan aduk dengan kecepatan tinggi selama 1,5-2 menit hingga benar-benar merata. Pelarut atau bahan pengencer lainnya tidak boleh ditambahkan selama pencampuran, dan menambahkan air sangat dilarang.

Catatan: Komponen C adalah komponen yang diperlukan dan harus ditambahkan selama pengadukan.

Rasio Pencampuran

Mencampur semua bahan baku dari set lengkap paket pabrik

Aplikasi

Sebelum mengikis primer, JINYU PAINT® MF perlu menuangkan bahan ke dalam alur dan mengikisnya hingga rata.

Lapisan Gores: Gunakan sekop datar atau sekop bergerigi 1mm untuk mengaplikasikan lapisan sesuai dengan jumlah yang telah ditentukan. Selama pengaplikasian, pastikan untuk mengikisnya hingga dekat dengan tanah dan pastikan kontinuitas lapisan untuk menghindari adanya titik yang terlewat.

Untuk permukaan beton dengan kekuatan dan kerataan yang rendah, disarankan untuk mengaplikasikan dua lapis lapisan awal untuk mendapatkan penyegelan dan kerataan yang lebih baik, yang dapat meningkatkan tampilan lapisan permukaan.

Lapisan Permukaan: gunakan penggaruk bergerigi atau sekop bergerigi 5 mm untuk satu kali penyebaran, dengan tenaga kerja yang cukup untuk menghindari sambungan. Jika areanya luas, isolasi yang sesuai dengan kertas dekoratif dapat digunakan terlebih dahulu pada sambungan.

Selama konstruksi pelapisan permukaan, hindari sinar matahari langsung dan suhu tinggi, karena dapat memengaruhi kinerja penghilang busa bahan pelapis dan menyebabkan banyak gelembung udara.

Sambungan Ekspansi: Sambungan ekspansi yang ada pada lantai beton harus ditandai sebelum konstruksi, dan kemudian dipotong lagi setelah pelapisan selesai, dan diisi dengan sealant sambungan poliuretan elastis yang sesuai.

Pembersihan

Bersihkan alat segera setelah aplikasi menggunakan pelarut. Serap bahan yang tumpah dengan pasir kering atau bahan penyerap lainnya dan bersihkan dengan kain.

Konsumsi Teoretis (4mm)

| Lapisan | Tingkat Aplikasi | Alat Aplikasi |

|---|---|---|

| Lapisan Gores | 1,8-2,0 kg/m² | Sekop bergerigi 1mm |

| Lapisan Permukaan | 6,0-6,5 kg/m² | Sekop bergerigi 5mm |

Penambahan atau pengurangan yang tidak wajar dalam aplikasi material dapat memengaruhi kualitas antarmuka, performa penyegelan, performa pengikatan, ketebalan lapisan, dll. Oleh karena itu, konsumsi produk harus mengikuti penggunaan yang direkomendasikan dan menyesuaikan dengan situasi aktual di tempat untuk mencapai kinerja yang ideal.

Waktu Aplikasi & Waktu Pengawetan

| Parameter | Kondisi | 20°C | 30°C |

|---|---|---|---|

| Kehidupan Pot | 25 menit | 15 menit | |

| Interval Minimal untuk pelapisan berikutnya | > 8 jam | 6 jam | |

| Waktu Pengawetan | Permukaan Kering | Lalu Lintas Ringan | Penyembuhan Penuh |

| + 20 ° C / 2mm | ~14-16h | ~24-36h | ~7d |