Deskripsi

JINYU® DT is a high-solid, polyurethane protective top coat engineered with ultra-hard white corundum aggregate. It delivers exceptional scratch resistance and abrasion resistance, boasting a surface hardness exceeding 5H. Designed for industrial floor coating applications that demand maximum durability, it is the ideal solution for warehouses, loading docks, and high-traffic areas. Its formula contains high-hardness white corundum aggregate, with a surface hardness of over 5H, and is commonly used in heavy traffic areas that require high wear resistance.

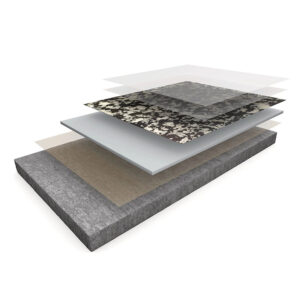

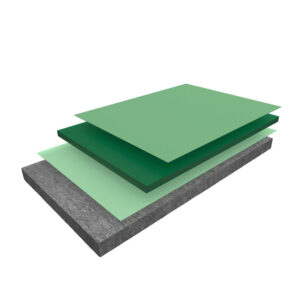

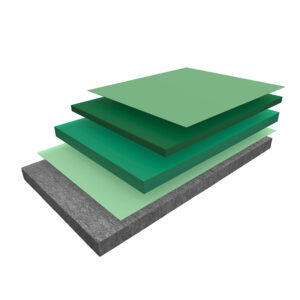

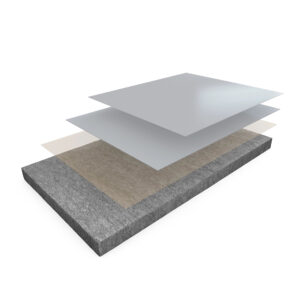

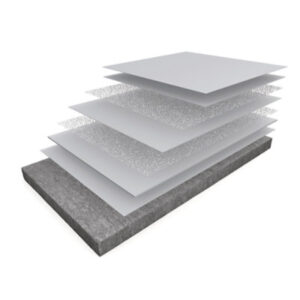

JINYU® DT should be used in combination with JINYU® MF1/2 self-leveling flooring for protective cover applications.

Applications for Our Heavy-Duty PU Coating

JINYU® DT is formulated to protect floors in the most demanding environments. Its superior performance makes it the perfect floor coating for warehouses and loading bays, where constant abrasion from forklifts and heavy goods is a daily challenge.

Beyond logistics, it is an excellent choice for:

Parking Garage Floor Coating: Resists tire marks, abrasion, and exposure to oils and chemicals.

Supermarket and Retail Flooring: Withstands high foot traffic and cart traffic while maintaining an attractive semi-matte finish.

Industrial and Manufacturing Plants: Offers outstanding chemical resistance against oils, acids, and solvents, protecting against spills and stains.

Consult the JINYU® solutions team for other specialized scenarios, including anti-static application requirements.

Key Features of Our Abrasion-Resistant Coating

Daya Tahan Tak Tertandingi: Achieves a 5H hardness rating for exceptional scratch resistance, outperforming standard epoxy and PU coatings.

Superior Abrasion Resistance: The integrated white corundum aggregate ensures minimal wear, even under the most intense heavy traffic conditions.

Long-Lasting Aesthetics: UV stable formula prevents yellowing and discoloration, maintaining a bright, clean appearance for years.

Excellent Chemical Resistance: Protects against a wide range of industrial chemicals, oils, and solvents, making it a true chemical resistant floor coating.

Safety and Comfort: Provides a semi-matte finish that reduces light glare and offers a sufficient coefficient of friction for safety.

Customizable Solutions: Can be formulated to support anti-static PU coating applications for electronics manufacturing and other sensitive environments.

Warna

There are five standard colors available (approximate):

yellow, beige, gules, blue, green, light gray, dark gray

Warna khusus dapat dipesan berdasarkan MOQ.

Pengemasan

JINYU® DT is a pre-packaged three-component

system, with a single set weighing 10kg:

Component A: 5 kg/bucket;

Component B: 2 kg/bucket;

Component C: 3 kg/package.

Parameter Teknis

Data berikut ini diukur dalam kondisi standar laboratorium dan mungkin memiliki sedikit perbedaan dari data aktual di lokasi.

| Item | Parameter |

|---|---|

| Penampilan | Setelah diaduk, campurannya seragam dan bebas dari gumpalan. |

| Pencil hardness (scratch resistance) | 5H |

| Ketahanan benturan (bola baja 1000g) | Tidak ada retakan atau pengelupasan |

| Kekuatan Rekat Tarik (Standar) | 2.7 N/mm² |

| Tensile Adhesion Strength (Soaking in water) | 2.0 N/mm² |

| Ketahanan terhadap abrasi (750g/500r) | 0.011g |

| Water Resistance (7D) | Tidak ada gelembung, Tidak ada pengelupasan, Tidak ada perubahan warna. |

| Resistance to Oil (Gasoline 120#, 7D) | Tidak ada gelembung, Tidak ada pengelupasan, Tidak ada perubahan warna. |

| Ketahanan terhadap Asam (10% H₂SO₄, 48 jam) | Tidak ada gelembung, Tidak ada pengelupasan, Tidak ada perubahan warna. |

| Ketahanan terhadap Basa (30% NaOH, 48 jam) | Tidak ada gelembung, Tidak ada pengelupasan, Tidak ada perubahan warna. |

| Ketahanan terhadap Garam (3% NaCl, 7D) | Tidak ada gelembung, Tidak ada pengelupasan, Tidak ada perubahan warna. |

| Anti-Slippery (dry friction coefficient) | 0.55 |

Standar

JINYU® DT complies with the relevant requirements of GB/T22374-2018 “Floor Coating Materials” standard.

Installation Instructions

Pencampuran

Before mixing, thoroughly stir component A (resin), and under low-speed mixing conditions (300-400 rpm), add the specified proportion of component B (hardener) and continuously stir for about 30 seconds. Then, slowly add component C (aggregate), and stir for 1 minute until a uniform mixture is obtained.

Catatan: Komponen C adalah komponen yang diperlukan dan harus ditambahkan selama pengadukan.

Application- Top Coating

The recommended consumption amount of the surface coating material is about 0.1 to 0.12 kg/m2. Use a metal flat trowel to evenly apply the coating material on the ground. Use a brush to handle the edge parts. The wet film thickness (WFT) should be controlled to around 0.1mm (dry film thickness (DFT) is around 0.09mm). Immediately use a short-haired roller to roll and coat evenly, cross-rolling in both vertical and horizontal directions once. This will result in a higher uniformity and a more aesthetically pleasing surface coating effect.

Pembersihan

Bersihkan alat segera setelah aplikasi menggunakan pelarut. Serap bahan yang tumpah dengan pasir kering atau bahan penyerap lainnya dan bersihkan dengan kain.

Theoretical Consumption

0.1~0.12kg/m2

Penambahan atau pengurangan yang tidak wajar dalam aplikasi material dapat memengaruhi kualitas antarmuka, performa penyegelan, performa pengikatan, ketebalan lapisan, dll. Oleh karena itu, konsumsi produk harus mengikuti penggunaan yang direkomendasikan dan menyesuaikan dengan situasi aktual di tempat untuk mencapai kinerja yang ideal.

Umur simpan

12 months from the date of production, if stored properly in original, unopened, and undamaged sealed packaging, in dry conditions at temperatures between +10 °C and +25 °C.

Part A must be protected from frost.

Part B must be protected from frost.

Part C must be protected from Humidity.

Rasio Pencampuran

Mixing all the raw materials from the complete set of factory packages.

Waktu Pengawetan

| Suhu | Permukaan Kering | Lalu Lintas Ringan | Penyembuhan Penuh |

|---|---|---|---|

| +10°C | ~30h | ~48h | ~6d |

| +20°C | ~16h | ~24h | ~4d |

| +30°C | ~12h | ~18h | ~3d |

Warna

There are five standard colors available (approximate)

Yellow: RAL 1006

Red: RAL 3002

Blue: RAL 5015

Green: RAL 6001

Grey: RAL 7037

Custom colors can be ordered based on Minimum Order Quantity (MOQ).