À Weihai, dans le Shandong, une nouvelle entreprise de production de fruits de mer a été confrontée à un défi majeur lors de la construction de l'usine : choisir le bon revêtement de sol pour la transformation des fruits de mer. Des problèmes tels que la corrosion due à l'eau salée, les dommages causés par l'humidité et les risques sanitaires menaçaient de retarder les opérations. L'équipe de l KAIDA JINYU® MF Système de plancher à base de mortier d'uréthane à base d'eau a fourni la solution idéale : un sol durable, hygiénique et respectueux de l'environnement, conçu spécifiquement pour les environnements de transformation des produits de la mer.

Quel est le meilleur revêtement de sol pour les usines de transformation des produits de la mer ?

Les sols des usines de transformation des produits de la mer doivent supporter des conditions extrêmes. L'exposition constante à l'eau salée, qui agit comme un puissant agent corrosif, entraîne une détérioration rapide des sols conventionnels, qui se traduit par de la rouille, des fissures et des surfaces qui s'écaillent. Les environnements humides favorisent les risques de glissade et la croissance bactérienne, ce qui complique la mise en conformité avec les normes internationales telles que HACCP. Sans un revêtement de sol approprié pour les usines de fruits de mer, Les entreprises sont confrontées à des coûts de maintenance croissants, à des risques en matière de sécurité et à des obstacles à la certification.

Pourquoi les sols en mortier d'uréthane KAIDA JINYU® sont le meilleur choix pour la transformation des fruits de mer ?

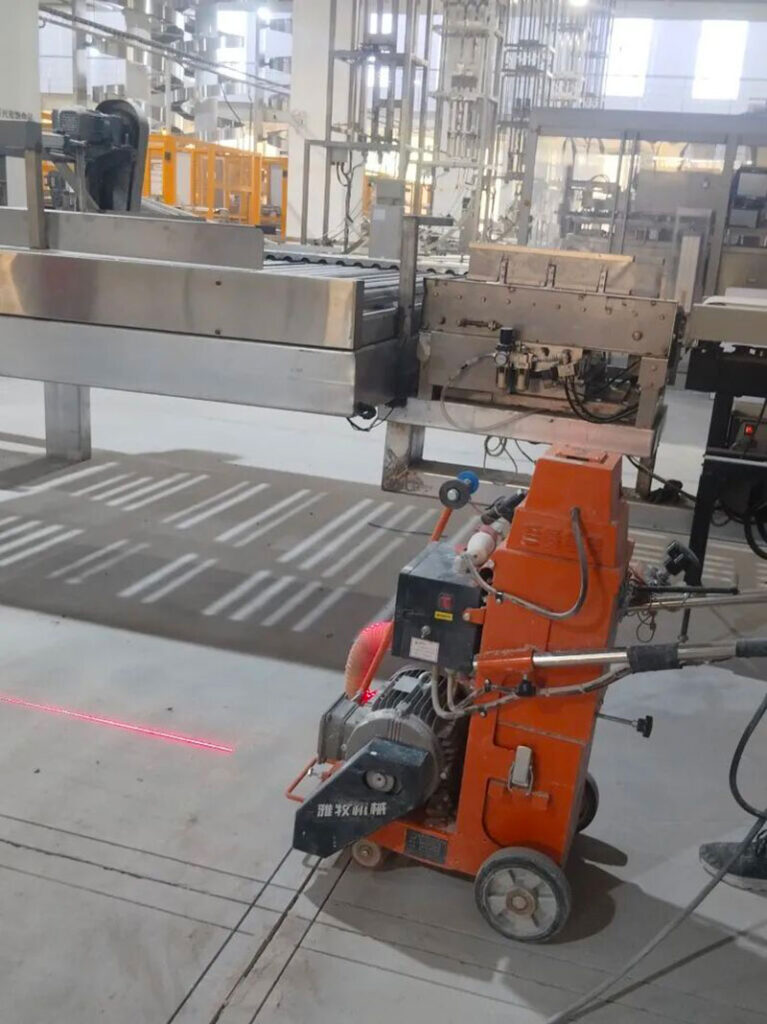

Fentes d'ancrage espacées de 80 cm : Réduisent les contraintes de rétraction et empêchent les infiltrations d'eau

- Les détails de la préparation du support déterminent la durée de vie du sol !

Résistance extrême à la corrosion

KAIDA JINYU®'s sol en mortier d'uréthane se caractérise par une structure moléculaire étroitement liée qui lui confère une protection semblable à celle d'une armure. Il résiste aux acides et aux alcalis dans une plage de pH de 2 à 12 et résiste à une exposition prolongée à l'eau salée, bloquant efficacement l'érosion par le chlorure et surpassant les matériaux de revêtement de sol standard.

Durabilité inégalée à toutes les températures

Le présent revêtement de sol en polyuréthane se comporte de manière cohérente aussi bien dans des environnements très froids (-40°C) que dans des environnements très chauds (jusqu'à 150°C). Il résiste à un trafic quotidien intense, y compris plus de 200 passages de chariots élévateurs, et offre une durée de vie allant jusqu'à 25 ans, ce qui permet de réduire considérablement l'entretien à long terme et de fournir un revêtement de sol fiable pour le traitement des fruits de mer.

Hygiène sans faille et conception écologique

Avec un rayon de 50 mm et une installation sans joint, le revêtement de sol KAIDA JINYU® élimine 90% les coins qui nuisent aux bactéries. Il est ainsi plus facile d'obtenir les certifications HACCP et autres certifications de sécurité alimentaire. La formule sans COV et sans odeur améliore la qualité de l'air intérieur et la sécurité des travailleurs. La finition vert clair améliore également la clarté visuelle et renforce l'image de marque écologique.

Succès du projet : Le financement durable des produits de la mer en action

KAIDA PAINT a soutenu l'entreprise de fruits de mer de Weihai avec un service de bout en bout, depuis l'inspection initiale du site et l'analyse des fondations jusqu'à la conception personnalisée et l'installation rapide. Le système à base d'eau a permis un durcissement rapide avec un minimum de perturbations. Aujourd'hui, l'établissement fonctionne avec un sol en mortier d'uréthane fiable et sans danger pour les aliments, qui stimule la productivité et la confiance dans la marque. Ce projet établit une nouvelle norme pour les revêtements de sol destinés à la transformation des fruits de mer en Chine et dans le monde.

Dans une industrie de plus en plus axée sur la qualité et la sécurité, il est essentiel de disposer d'un revêtement de sol performant. La technologie du mortier d'uréthane de KAIDA JINYU®, associée à un soutien professionnel, transforme les normes de revêtement des sols des usines de fruits de mer et ouvre la voie à l'avenir des sols industriels sanitaires.