Beskrivning

Produktöversikt

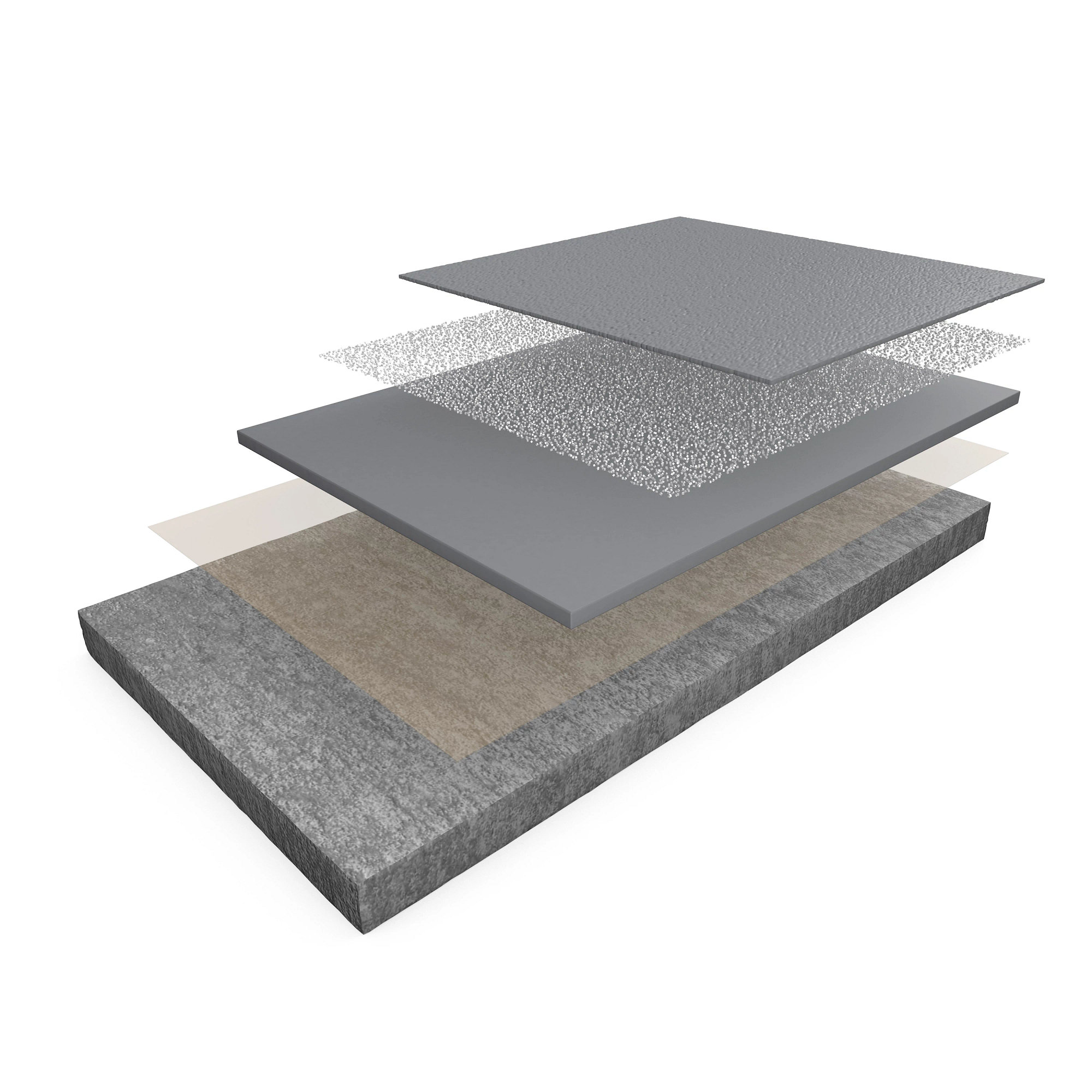

Ure-Crete™ MDB is a premium, 1/4-inch thick, seamless cementitious urethane flooring system designed for demanding industrial and commercial environments. It combines the strength of cement with the flexibility and chemical resistance of advanced polyurethane chemistry, forming a monolithic, textured floor that is both durable and functional. The system delivers exceptional impact resistance, moisture mitigation, and a slip-resistant finish with broadcast quartz aggregate. This makes Ure-Crete™ MDB the ideal flooring solution for facilities like warehouses, food processing plants, manufacturing areas, and high-traffic commercial spaces where durability, safety, and hygiene are non-negotiable.

User Pain Points & Scenario Analysis

Industrial and commercial flooring faces relentless challenges that standard concrete or epoxy coatings cannot withstand. Common pain points include:

Cracking & Degradation: Heavy forklift traffic and impact from dropped tools cause standard floors to crack and spall, creating dust and unsafe conditions.

Chemical Attack: Spills from oils, greases, acids, and sanitizers in food & beverage or automotive companies degrade floors, leading to contamination and costly repairs.

Moisture Problems: Moisture vapor transmission from subfloors can cause blistering and delamination of impermeable coatings.

Hygiene & Cleanability: Porous or cracked floors harbor bacteria and are difficult to sanitize, failing health department audits in facilities like dairies or industrial kitchens.

Poor Aesthetics & Safety: Worn-out, stained floors project a poor image, while slick surfaces when wet pose a significant slip-and-fall risk.

Specific Scenarios:

Food & Beverage Plants: Need a sealer-like, impervious finish that withstands daily harsh chemical cleaning, hot water, and steam, while meeting USDA/FDA compliance.

Logistics Warehouses: Require a system with extreme abrasion and impact resistance to handle constant pallet jack and forklift traffic without wearing down.

Automotive Workshops: Demand resistance to petroleum products, anti-freeze, and hot tire pick-up, combined with easy cleanup.

Product Solution & Key Features

The Ure-Crete™ MDB cementitious urethane flooring system is engineered to directly address these challenges. Here are its core selling points:

Unmatched Mechanical & Physical Performance

Extreme Durability: With a high compressive strength (exceeding 7,800 psi) and excellent abrasion resistance (low Taber wear loss), this urethane mortar outlasts standard concrete and many epoxy systems.

Superior Impact & Thermal Shock Resistance: The elastic polyurethane matrix absorbs impacts that would crack brittle materials and withstands rapid temperature changes without failure.

Moisture Mitigating: Unlike many coatings, it can be installed over concrete with up to 99% relative humidity (ASTM F-2170), often eliminating the need for costly vapor barriers.

Slip-Resistant Finish: The integrated natural quartz aggregate broadcast provides a textured, slip-resistant surface even when wet, enhancing safety.

Proven Chemical Resistance

The 100% solids, seamless finish acts as a barrier against a wide range of chemicals commonly found in industrial settings, including:

Oils, Greases, and Aliphatic Hydrocarbons

Dilute Acids and Alkalis

Water, Salts, and Sanitizers

This makes cleanup simple and protects the substrate from degradation.

Hygienic & Customizable Aesthetics

Sömlös och icke-porös: With no grout lines or joints, it prevents bacterial growth and allows for easy, thorough cleaning.

UV-Stable Topcoat Options: Available topcoats resist yellowing from sunlight or UV lighting, maintaining color integrity.

Color & Texture Options: Available in standard and custom colors to match corporate branding or functional zoning needs.

Efficient Installation & Sustainability

Fast-Curing & Productive: The system allows for rapid return-to-service, minimizing facility downtime for contractors and owners.

Low-VOC & Environmentally Preferred: With 0 g/L VOC and compliance with stringent indoor air quality standards (e.g., CA Section 01350), it contributes to healthier indoor environments.

Technical Specifications & Authoritative Data

The performance of Ure-Crete™ MDB is backed by rigorous testing against international standards, providing contractors and specifiers with reliable data.

| Fastighet | Testmetod | Typical Value | Performance Benefit |

|---|---|---|---|

| Tryckhållfasthet | ASTM C-579 | > 7,800 psi | Withstands extreme point loads |

| Draghållfasthet | ASTM D-638 | > 4,200 psi | High cohesion and crack resistance |

| Flexural Strength | ASTM D-790 | > 5,000 psi | Resists bending under load |

| Motståndskraft mot nötning | ASTM D-4060 (CS-17 Wheel) | ~30 mg loss | Exceptional long-term wear life |

| Hårdhet | ASTM D-2240 (Shore D) | 65 D | Tough yet slightly flexible surface |

| Bindningsstyrka | ASTM D-4541 | > 400 psi (concrete substrate fails) | Superior adhesion prevents delamination |

| VOC-innehåll | EPA Method 24 | 0 g/L | Safe for occupied environments |

| Moisture Tolerance | ASTM F-2170 | Up to 99% RH | Installs in damp conditions |

Tillämpningsområden

The versatility of the cementitious urethane system makes it suitable for a vast range of sectors:

Bearbetning av livsmedel och drycker: Breweries, dairies, meat packing plants, commercial kitchens.

Lagerhållning och logistik: Distribution centers, bulk storage, cold storage facilities.

Manufacturing: Automotive plants, aerospace facilities, machine shops, tool cribs.

Commercial & Institutional: School corridors, hospital back-of-house, airport maintenance areas.

Parking & Utility Areas: Industrial parking decks, loading docks, mechanical rooms.

Installation Process & Technical Support

A successful installation relies on proper preparation and expert application. KAIDA PAINT supports contractors every step of the way.

Key Installation Steps:

Substrate Preparation: Concrete must be shot-blasted to a CSP 3-5 profile, clean, dry, and sound. Keyways (1/4″ x 1/4″) are cut at perimeters.

Priming (Optional): In most cases, the moisture-mitigating cementitious body coat eliminates the need for a primer.

Body Coat & Broadcast: The urethane cement mortar (Ure-Crete MD) is mixed and applied at a 3/16″ thickness, then immediately broadcast with quartz aggregate (Flintshot).

Applicering av topplack: After curing, a protective polyurethane topcoat (e.g., Ure-Crete TF Plus) is applied for enhanced chemical and abrasion resistance.

Curing: The system requires proper cure time before returning to full service (minimum 8-24 hours depending on temperature).

Our Technical Support Includes:

Free on-site concrete moisture and condition evaluation.

Detailed, project-specific specification and technical data sheets.

Direct access to our technical service team for contractors during installation.

Quality control guidelines to ensure the finished floor meets performance expectations.

Vanliga frågor och svar (FAQ)

What is the main difference between a cementitious urethane floor and an epoxy floor?

Cementitious urethane systems like Ure-Crete™ MDB combine inorganic cement with organic polyurethane, resulting in a floor that is more flexible, resistant to thermal shock, and tolerant of moisture in the concrete slab. Epoxy is typically more rigid and can be brittle, making it more susceptible to cracking under impact or thermal stress.

What is the typical installed cost of a cementitious urethane flooring system?

The total cost varies based on substrate condition, project size, location, and chosen finish. As a premium, high-performance industrial flooring solution, it represents a long-term investment with a lower total cost of ownership due to its exceptional durability and reduced maintenance needs. Contact us for a project-specific quote.

How long does the installation process take?

For a typical project, the installation can often be completed in 2-4 days, depending on area size and conditions. The system allows for rapid cure, enabling a quick return to service, which minimizes downtime for facility managers and companies.

Can this system be installed over existing concrete with cracks?

Yes. The urethane mortar has excellent crack-bridging capabilities. However, active structural cracks must be addressed, and all cracks are typically prepared by routing and filling per manufacturer specifications to ensure a long-lasting finish.

What maintenance is required for a Ure-Crete™ MDB floor?

Maintenance is simple. Regular sweeping and occasional damp mopping with a neutral pH cleaner are usually sufficient. The seamless, non-porous surface does not require waxing or stripping. Avoid harsh acidic cleaners to preserve the topcoat.

Social Proof & Trust Building

Proven in Demanding Sectors: Ure-Crete™ MDB systems are specified by leading companies in food processing, automotive, and logistics across North America.

Comprehensive Compliance: The products are formulated to comply with relevant USDA, FDA, and health department guidelines for sanitary flooring, and meet strict indoor air quality standards.

Quality Assured: Our manufacturing and technical support processes ensure consistent, high-quality products. We partner with experienced, certified contractors to guarantee proper installation.

Partner with KAIDA PAINT

At KAIDA PAINT, we specialize in engineering advanced protective coatings and flooring systems that stand up to the toughest industrial challenges. We understand that your facility’s floor is a critical asset, impacting safety, productivity, and operational cost. That’s why we developed the Ure-Crete™ MDB Cementitious Urethane Flooring System.

Our advantage lies in a relentless focus on performance and partnership. We don’t just sell products; we deliver comprehensive solutions. From initial consultation and substrate analysis to providing detailed technical specifications and supporting certified contractors during installation, our team is with you at every step. The Ure-Crete™ MDB system embodies this commitment, offering a unique blend of cementitious durability and urethane flexibility that outperforms conventional options.

If you’re looking for a flooring partner who provides more than just paint, but a proven system backed by expertise and support, look no further. Contact KAIDA PAINT today for a consultation and discover the difference a true performance flooring solution can make.