Beskrivning

Product Overview:

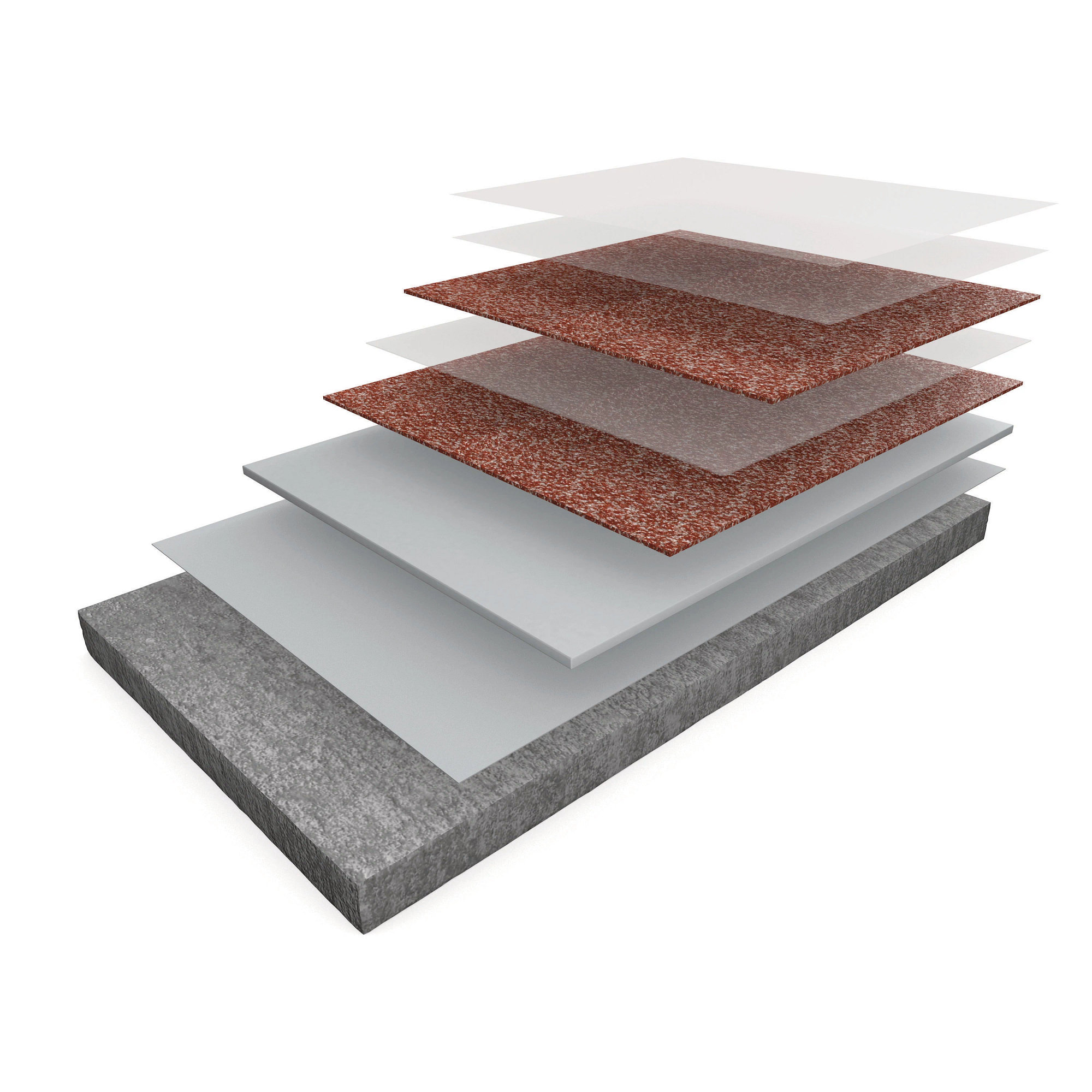

TerraFlex™ EQ is a state-of-the-art, seamless cementitious urethane flooring system designed for high-traffic industrial, commercial, and institutional environments. This system combines a moisture-tolerant, self-priming, and self-leveling urethane mortar body coat with a double broadcast of decorative quartz aggregate. Finished with a high-performance aliphatic urethane topcoat, it delivers exceptional chemical, UV, and abrasion resistance. The result is a durable, low-maintenance, and visually appealing floor that solves common problems like cracking, dusting, and chemical attack, providing a long-lasting solution for facilities that demand performance and aesthetics.

The Problem: Why Standard Concrete and Epoxy Floors Fail

Industrial and commercial floors face relentless challenges. Bare concrete is porous, generating dust, absorbing spills, and cracking under stress. Many coating products, like standard epoxies, can be brittle, prone to yellowing from UV exposure, and fail in damp conditions or under thermal cycling. For contractors and facility managers, this means frequent repairs, downtime, safety hazards, and unsatisfied clients.

Anläggningar för mat och dryck: Require seamless, chemical-resistant floors that can withstand daily washdowns with harsh sanitizers, hot water, and acidic/alkaline spills, all while meeting strict hygiene standards.

Logistics & Warehouses: Need floors that can endure constant impact from heavy forklift traffic, abrasion from pallet dragging, and thermal shocks from loading dock doors.

Pharmaceuticals & Laboratories: Demand non-porous, easy-to-clean surfaces that resist a wide range of solvents and chemicals, contributing to controlled environments.

Commercial Spaces (Lobbies, Retail, Schools): Seek a durable yet decorative finish that is slip-resistant, easy to maintain, and can handle high foot traffic without showing wear.

The TerraFlex™ EQ Solution: Engineered for Extreme Performance

Our cementitious urethane system is specifically formulated to outperform conventional flooring options. It’s not just a coating; it’s a hybrid system that merges the best properties of urethane and cement.

Superior Mechanical Durability: The cementitious urethane mortar matrix provides outstanding compressive strength (exceeding 17,500 psi) and impact resistance (>160 inch-lbs), preventing cracks from propagating through the slab. Its abrasion resistance ensures a long-lasting finish even under heavy wheeled traffic.

Exceptional Chemical & Moisture Resistance: Unlike many paint or thin-film products, TerraFlex™ EQ is moisture-mitigating. It can be applied to concrete with high moisture vapor emission and resists a broad spectrum of chemicals, oils, and solvents commonly found in industrial settings. The aliphatic urethane topcoat provides superior UV stability, preventing yellowing and degradation.

Förbättrad säkerhet och rengörbarhet: The textured quartz broadcast creates a slip-resistant surface, meeting ADA and OSHA guidelines for wet and dry conditions. The seamless, non-porous finish eliminates grout lines and cracks where bacteria and dirt can hide, making it exceptionally easy to clean and sanitize.

Decorative Flexibility & Thermal Stability: Available in a wide palette of blended and solid quartz colors, it offers a unique aesthetic for any space. The system is resistant to thermal cycling, making it suitable for environments with significant temperature fluctuations.

Tekniska specifikationer & data

The performance of TerraFlex™ EQ is backed by rigorous testing against international standards, giving companies and specifiers confidence in its capabilities.

| Fastighet | Testmetod | Typical Value |

|---|---|---|

| Systemets tjocklek | Nominal | 3/16″ – 1/4″ |

| Tryckhållfasthet | ASTM D-695 | 17,500 psi |

| Draghållfasthet | ASTM D-638 | 4.000 psi |

| Flexural Strength | ASTM D-790 | 6,250 psi |

| Hårdhet (Shore D) | ASTM D-2240 | 75-80 |

| Abrasion Resistance (w/ grit) | ASTM D-4060 | 4 mg loss |

| Kemisk beständighet | Per Manufacturer | Excellent to a wide range |

| Slip Resistance (Wet/Dry) | ANSI A326.3 / B101.1 | >0.42 / >0.6 |

| VOC-innehåll | - | <5 g/L |

| Temperatur vid drift | - | Up to 140°F – 200°F |

Ideal Applications for TerraFlex™ EQ

This versatile cementitious urethane flooring is the specified choice for demanding environments across numerous sectors:

Cleanrooms & Pharmaceutical Manufacturing

Food & Beverage Processing & Packaging

Chemical & Industrial Plants

Automotive & Aerospace Facilities

Laboratorier och utbildningsinstitutioner

Kommersiella kök & bryggerier

Logistics Centers & Warehouses

Retail Supermarkets & High-Traffic Lobbies

Animal Care & Kennels

Professional Installation Process

Proper installation is critical to achieving the designed performance. TerraFlex™ EQ requires professional application by certified contractors. The key steps include:

Substrate Evaluation & Preparation: Concrete is shot-blasted to a CSP 3-5 profile. Critical moisture testing (ASTM F-2170) is performed.

Primer Application (if needed): A moisture-tolerant primer is applied on porous substrates.

Body Coat & 1st Broadcast: The self-leveling cementitious urethane mortar is poured, screeded, and immediately broadcast with decorative quartz.

2nd Broadcast & Grout: An epoxy resin coat is applied, broadcast with more quartz, and then sealed with a grout coat to fill the aggregate.

Applicering av topplack: The final layer of high-performance aliphatic urethane is rolled on, providing chemical and UV resistance.

Curing & Protection: The floor is protected during the full 7-day cure for optimal chemical resistance.

We provide comprehensive technical support, from specification and substrate analysis to on-site guidance, ensuring your project’s success.

Vanliga frågor och svar (FAQ)

What is the difference between cementitious urethane and epoxy flooring?

Cementitious urethane systems like TerraFlex™ EQ offer superior flexibility, thermal shock resistance, UV stability, and moisture tolerance compared to traditional epoxies. They are less brittle and better suited for environments with temperature changes or potential substrate movement.

How long does it take to install TerraFlex™ EQ?

The installation timeline depends on the area size and site conditions. Typically, the multi-coat system requires several days for application and curing. Full chemical and abrasion resistance is achieved after 7 days at 77°F.

What is the typical cost of a cementitious urethane flooring system?

The cost varies based on project size, substrate condition, design complexity, and geographic location. As a premium, high-performance system, it represents a long-term investment that reduces lifetime maintenance and replacement costs. Contact us for a detailed quote.

How do I maintain a TerraFlex™ EQ floor?

Maintenance is simple. Regular sweeping and damp mopping with a neutral pH cleaner are usually sufficient. Avoid harsh abrasive cleaners. The seamless finish and durable topcoat make it easy to keep clean and looking new for years.

Betrodda av industriledare

TerraFlex™ EQ is specified by leading companies in food processing, pharmaceuticals, and manufacturing who cannot afford floor failure. Our systems are designed to meet or exceed the requirements of USDA, FDA, and California Section 01350 for indoor air quality. We partner with a network of highly trained and experienced contractors to ensure flawless execution on every project.

Är du redo att förändra ditt golv?

Don’t settle for a floor that can’t keep up with your operational demands. The investment in a TerraFlex™ EQ cementitious urethane flooring system pays dividends in durability, safety, and reduced total cost of ownership.

About KAIDA PAINT & Your Project Partner

At KAIDA PAINT, we are more than just a manufacturer of high-performance industrial coatings; we are your dedicated solutions partner. With deep expertise in urethane and cementitious technologies, we develop products like TerraFlex™ EQ to solve real-world flooring challenges. Our strength lies in our end-to-end support:

Teknisk expertis: Our team provides specification guidance, detailed CAD details, and job-specific technical data sheets.

Contractor Network: We work with a qualified network of professional flooring contractors to ensure superior installation.

Project Support: From initial moisture testing to final inspection, we are involved to help guarantee a successful outcome.

Let’s discuss your next project. Contact KAIDA PAINT today for a free consultation, substrate evaluation, or to request material samples and pictures of completed installations. Discover why leading companies trust us with their most demanding flooring challenges.