Beskrivning

Produktöversikt

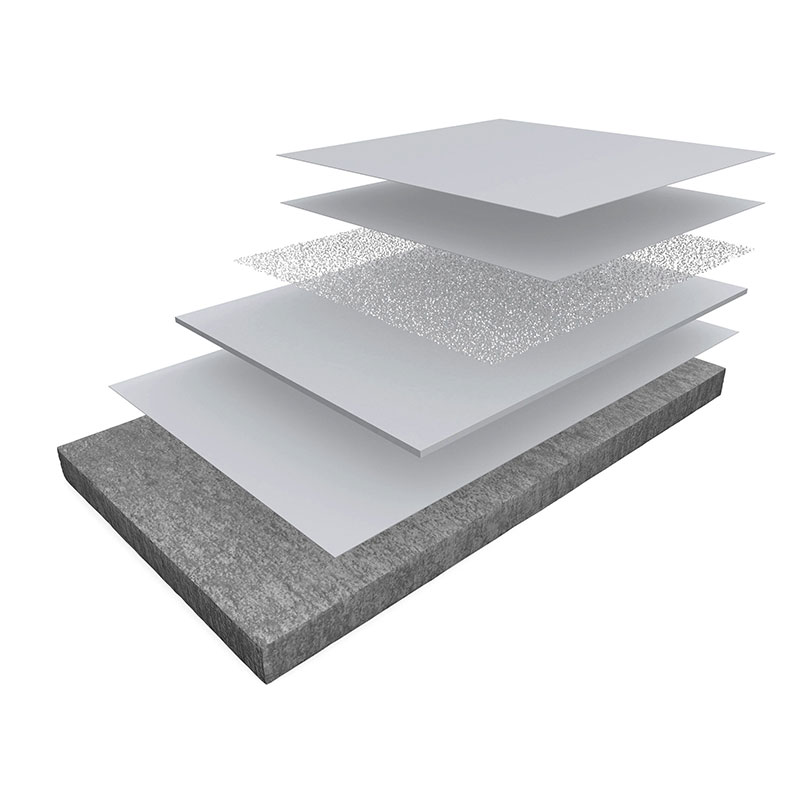

ResuShield™ Shop Floor SB is a high-performance, nominal 1/16-inch thick epoxy flooring system engineered for demanding industrial environments. By combining a high-solids epoxy resin with a full broadcast of durable silica sand, it creates a seamless, multi-layer shield over interior concrete. This system delivers exceptional abrasion resistance, superior chemical protection, and customizable slip resistance. Designed for longevity under heavy traffic, ResuShield™ Shop Floor SB provides a cost-effective and durable solution for manufacturing plants, warehouses, vehicle shops, and other high-use commercial spaces.

Understanding Your Industrial Flooring Challenges

Industrial and commercial floors face relentless abuse, leading to costly repairs, safety hazards, and operational downtime. Common pain points for facility managers and contractors include:

Dusting and Degradation: Untreated or worn concrete creates dust, contaminating products and machinery, and leading to a poor finish.

Cracking and Spalling: Heavy equipment and impact can crack standard cement floors, requiring frequent repair.

Chemical Damage: Exposure to oils, greases, solvents, and cleaning agents can stain and deteriorate many flooring types.

Safety Concerns: Slippery surfaces, especially when wet, pose a significant risk in areas like locker rooms, kitchens, and pool decks.

Difficult Cleaning: Porous or textured surfaces trap dirt, making them hard to clean and maintain to sanitary standards.

Kort livslängd: Inexpensive paint or coatings quickly wear through, leading to a high long-term cost.

Whether you’re a contractor installing a floor for a client or a company managing your own facility, these issues impact your bottom line and operational efficiency.

The ResuShield™ Solution: Detailed Features & Benefits

ResuShield™ Shop Floor SB directly addresses these challenges with a robust, multi-coat system.

1. Unmatched Durability & Mechanical Performance

This system is built to last. The epoxy resin deeply penetrates the concrete base, creating a powerful bond that withstands heavy loads and impact.

Abrasion Resistance: With a Taber Abraser (CS-17 wheel, 1000g load) result of only 18 mg loss (ASTM D4060), it far outperforms standard industrial paint.

High Strength: Features a compressive strength of 13,500 psi (ASTM D695) and tensile strength of 8,000 psi (ASTM D2370).

Utmärkt vidhäftning: The coating achieves such strong adhesion (732 psi per ASTM D7234) that during testing, the concrete substrate fails before the epoxy bond.

2. Enhanced Safety with Customizable Slip Resistance

Safety is non-negotiable. The broadcast layer of silica sand provides a textured, skid-inhibiting surface.

Wet Static Coefficient of Friction (SCOF): Scores 0.94 (ANSI/NFSI B101.1), indicating high slip resistance in wet conditions, ideal for food areas, showers, and ramps.

James Machine COF: A dry static COF of 0.63 (ASTM D2047) ensures secure footing in dry industrial settings.

3. Superior Chemical & Stain Resistance

Protect your subfloor from a wide range of common industrial substances. The high-solids epoxy and durable urethane topcoat create a non-porous, seamless shield that resists penetration from oils, greases, and many chemicals, simplifying cleaning and maintenance.

4. Seamless, Hygienic & Easy to Clean

Unlike tile or cracked concrete, this system provides a seamless finish with no grout lines or cracks to harbor dirt, moisture, or bacteria. This makes it ideal for businesses requiring high hygiene standards, such as in animal facilities or food processing areas. Daily maintenance is simple with dust mopping and periodic damp mopping.

5. Long-Lasting Aesthetics & Customization

Move beyond dull, gray concrete. ResuShield™ offers a range of standard and custom colors to improve lighting and facility appearance. The satin urethane topcoat provides a light-stable finish that resists yellowing from UV exposure (tested per ASTM G154), ensuring your floor looks professional for years.

Tekniska specifikationer & data

| Fastighet | Testmetod | Result/Value |

|---|---|---|

| Systemets tjocklek | Nominal | 1/16 inch |

| Motståndskraft mot nötning | ASTM D4060 | 18 mg loss |

| Vidhäftning till betong | ASTM D7234 | 732 psi (concrete failed) |

| Tryckhållfasthet | ASTM D695 | 13,500 psi |

| Draghållfasthet | ASTM D2370 | 8,000 psi |

| Hårdhet (Shore D) | ASTM D2240 | 80-85 @ 0 sec |

| Våt statisk COF | ANSI/NFSI B101.1 | 0.94 |

| Dry Static COF | ASTM D2047 | 0.63 |

| VOC Content (Mixed) | ASTM D3960 | <50 g/L |

| Topcoat Yellowing Resistance | ASTM G154/ASTM D2244 | <10 Δb after 1000 hrs QUV |

Ideal Application Areas

ResuShield™ Shop Floor SB is the best choice for a wide range of heavy-traffic and demanding environments:

Manufacturing & Assembly Plants: Handles heavy machinery and foot traffic.

Warehouses & Logistics Centers: Resists damage from pallet jacks and forklifts.

Vehicle Maintenance & Repair Shops: Shields against oil, grease, and tire marks.

Commercial Kitchens & Food Processing: Provides slip resistance and easy cleaning.

Fire Stations, Hangars & Public Works: Durable enough for emergency vehicles and equipment.

Animal Facilities & Kennels: Creates a seamless, sanitizable surface.

Parking Garages & Low-Level Ramps: Offers durability and weather resistance.

Professionell installation och support

For optimal performance, professional installation by qualified contractors is recommended. The key steps include:

Surface Preparation & Repair: Concrete is shot-blasted to a CSP 3-5 profile (ICRI 310.2R) to ensure a clean, sound base. Cracks are filled.

Primer Applicering: A coat of epoxy primer seals the concrete, promoting adhesion.

Broadcast Coat: Epoxy is applied, and silica sand is broadcast into it for texture and strength.

Grout Coat: A second epoxy coat encapsulates the sand layer.

Topcoat/Sealer Application: A final coat of durable, satin-finish urethane (Resutile HTS 100) is applied for chemical resistance and a uniform finish.

We provide comprehensive technical data sheets, application guides, and access to our support team to ensure your project’s success from prep to final cure.

Vanliga frågor och svar (FAQ)

Q: How does ResuShield™ Shop Floor SB compare to a basic epoxy paint kit?

A: It is a far more robust system. While DIY epoxy paint is a thin coating, ResuShield™ is a 4-layer, 1/16-inch thick system with a broadcast aggregate for physical strength and slip resistance. It’s designed for commercial/industrial abuse, not residential garage use.

Q: What is the typical cost per square foot installed?

A: The final price depends on the concrete condition, floor size, and geographic location. For an accurate quote tailored to your specific project, please contact us or an authorized installer. It is a cost-effective long-term solution compared to frequent repairs of lesser systems.

Q: How long does installation take, and when can I use the floor?

A: After the 7-day concrete cure, system installation typically takes several days depending on area size. The floor can accept light traffic after 24 hours but requires 7 days before wet cleaning and 14 days for full cure and heavy use.

Q: Can it be applied in my basement or over existing tile?

A: It is designed for interior concrete slabs-on-grade. Special preparation and consultation are required for basement slabs (moisture testing per ASTM F2170 is critical) or over other substrates like tile or metal. Contact our technical team for guidance.

Q: How do I clean and maintain this flooring system?

A: Daily dust mopping and prompt cleanup of spills are recommended. For periodic cleaning of the textured surface, use a bristle brush with a mild cleaner, followed by rinsing. Always test cleaners in a small area first.

Trust & Proven Performance

ResuShield™ Shop Floor SB is manufactured to the highest standards, with performance data verified by independent ASTM test methods. Our products are specified by architects and used by contractors and companies worldwide for demanding projects, from global manufacturing facilities to local vehicle service centers. We stand behind our products with comprehensive technical support and warranties.

KAIDA PAINT Brand Introduction

Your Trusted Partner in High-Performance Flooring Solutions

At KAIDA PAINT, we understand that your floor is a critical business asset. That’s why we go beyond being just a paint or coating supplier. We are your solution partner, dedicated to providing companies and professional contractors with advanced, reliable flooring systems like ResuShield™ Shop Floor SB that stand up to real-world industrial challenges.

Our expertise lies in formulating epoxy and polyurethane resin-based products that offer superior resistance to abrasion, chemicals, and impact. We focus on delivering not just a product, but a complete application solution—from helping you prepare the concrete base and choose the right finish (whether gloss, satin, or slip-resistant), to providing ongoing support for cleaning and repair.

Whether you’re managing a warehouse, a commercial kitchen, a factory, or a residential garage project, we have the best system for your needs and budget. We offer a range of colors, from standard gray and white to custom designs with flakes, and kits suitable for various square footages.

Don’t settle for a cheap, short-term fix that will crack under pressure. Partner with KAIDA PAINT for a professional, long-lasting finish. Contact our team today for a detailed consultation, a competitive price quote, and to find an authorized Installer near you. Let’s build a better base for your business.

Contact us today for:

A detailed quote based on your square footage.

Technical specifications and product data sheets.

Referrals to qualified installers in your city or country.

Answers to all your project-specific questions.