Beskrivning

ResuShield™ Shop Floor MR is a seamless, slip-resistant pigmented epoxy flooring system designed for demanding industrial environments. Combining 100% solids epoxy resin with durable natural quartz aggregates and a protective urethane topcoat, this system delivers unmatched abrasion resistance, chemical resilience, and long-term performance. It is the definitive solution for mechanical rooms, data centers, warehouses, and facilities where durability, safety, and low maintenance are non-negotiable.

The Industrial Flooring Challenge: Common Pain Points for Companies & Contractors

Industrial and commercial facilities face relentless challenges with their concrete floors. Facility managers and contractors constantly battle:

Cracking and Degradation: Constant foot and vehicle traffic leads to unsightly cracks, pitting, and dusting, creating a dirty, unprofessional appearance and contaminating sensitive areas like server rooms.

Chemical and Moisture Attack: Spills from oils, coolants, and cleaning agents can degrade standard cement or paint, leading to costly repairs and downtime. Vapor transmission from slabs can cause coating failure.

Säkerhetsrisker: Slick surfaces, especially when wet, pose significant slip-and-fall risks. Uneven surfaces from wear can cause trip hazards.

High Maintenance & Cost: Frequent cleaning, patching, and recoating drain operational budgets. The need for a durable, long-lasting finish is a critical business decision.

For contractors, selecting the right flooring system impacts project timelines, client satisfaction, and long-term performance. The wrong product choice can lead to callbacks, warranty claims, and reputational damage.

The ResuShield™ Shop Floor MR Solution: Engineered for Performance

Our epoxy flooring system is not just a coating; it’s a complete, integrated solution designed to address these exact pain points. Here’s what sets it apart:

1. Unmatched Durability & Mechanical Performance

Extrem nötningsbeständighet: With a Taber Abrasion loss of only 29 mg (CS-17 Wheel, ASTM D-4060), it withstands constant traffic from heavy equipment and steel-wheeled carts far better than standard industrial paint or sealers.

Superior Impact & Indentation Resistance: Passes MIL-D-3134 tests, ensuring the finish won’t crack or dent under dropped tools or heavy loads.

Hög draghållfasthet: 4,000 psi tensile strength (ASTM D-638) provides a robust, long-wearing surface that resists mechanical stress.

2. Advanced Chemical & Environmental Resistance

Chemical-Resistant Topcoat: The UV-stable urethane topcoat provides a resilient barrier against a wide range of chemicals, oils, and solvents common in mechanical and equipment rooms.

100% Solids, Low-VOC Formula: Contains no solvents, reducing odor and environmental impact while providing a thicker, more durable build per coat compared to water-based products.

Moisture Tolerance: Optional Resuprime™ MVP primer/moisture barrier system protects against vapor transmission, making it suitable for use over new or problematic concrete slabs.

3. Safety & Functional Benefits

Slip-Resistant Finish: Textured aggregates provide a high-traction surface, with a static coefficient of friction >0.6 (ANSI B101.1), even when wet, enhancing workplace safety.

Sömlös och hygienisk: The monolithic finish eliminates grout lines and joints where dirt and bacteria can hide, making it exceptionally easy to clean and maintain. It’s ideal for food processing or pharmaceutical areas.

Wide Application Window: Can be installed over new or old concrete, offering a versatile solution for renovations and new construction.

4. Aesthetic Flexibility & Professional Finish

Color & Finish Options: Available in a range of standard and custom colors with satin or gloss sheens. Integrate flakes or quartz for decorative design in commercial spaces.

Smooth, Professional Appearance: Creates a bright, clean, and modern look for warehouses, showrooms, and industrial facilities, improving the overall work environment.

Technical Specifications & Authoritative Data

| Fastighet | Testmetod | Value/Result |

|---|---|---|

| Systemets tjocklek | Nominal | 1/8″ (with double broadcast) |

| Draghållfasthet | ASTM D-638 | 4.000 psi |

| Motståndskraft mot nötning | ASTM D-4060 (CS-17 Wheel) | 29 mg loss |

| Water Absorption | ASTM D-570 | 0.04% |

| Kemisk beständighet | Standard Topcoat | Resistant to oils, greases, many chemicals |

| Slip Resistance (Wet) | ANSI A326.3 | Dynamic Coefficient of Friction >0.42 |

| UV-beständighet | - | Excellent, no ambering |

| Topcoat VOC | - | 0 g/L (Resutile AT) |

Key Application Areas

The ResuShield Shop Floor MR system is engineered for heavy-duty use across diverse sectors:

Mechanical & Equipment Rooms: Protects floors around HVAC, boilers, and machinery.

Data Centers & Server Rooms: Provides static-control-friendly, durable, and dust-free flooring.

Industrial Warehouses & Logistics: Withstands extreme abrasion from forklifts and pallet jacks.

Manufacturing & Processing Plants: Resists chemical spills and heavy impact in factory settings.

Commercial Garages & Parking Areas: Offers a durable, easy-to-clean surface with good slip resistance.

Anläggningar för mat och dryck: Provides a seamless, sanitizable surface that meets hygiene standards.

Professional Installation Process

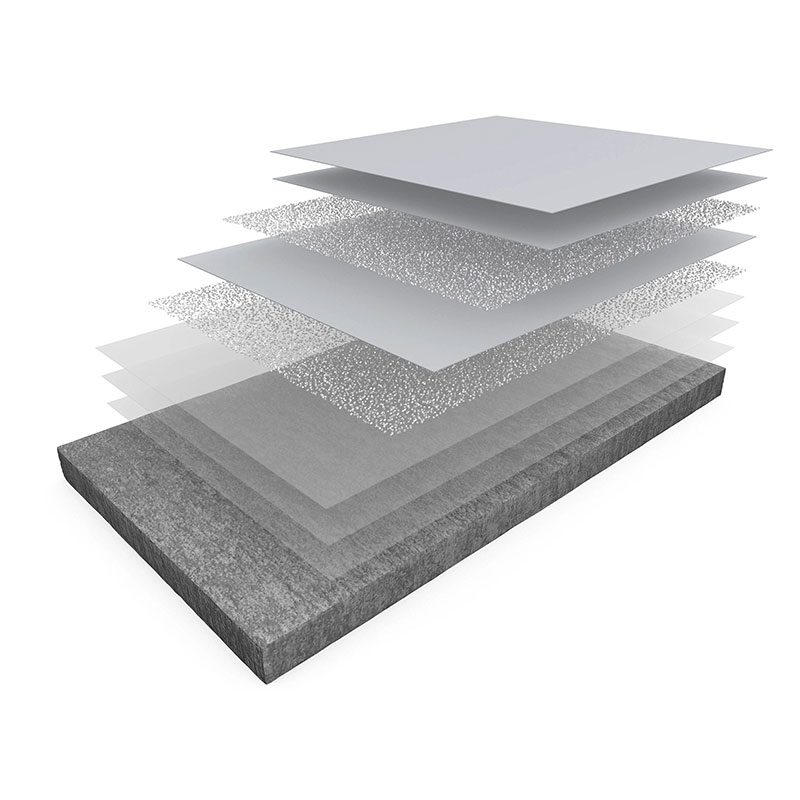

A successful installation is key to performance. Our recommended process ensures optimal results:

Surface Preparation (Prep): Shot blasting or grinding to a CSP 3-4 profile to ensure perfect adhesion. Critical moisture testing (ASTM F-1869/F-2170) is performed.

Priming/Moisture Barrier (Prime): Application of Resuprime MVP (if required) to mitigate vapor.

Waterproofing Membrane: Application of Resuflor EOC membrane for critical waterproofing areas.

Broadcast Coats (Basecoat): Double broadcast of Flintshot quartz aggregate into pigmented epoxy resin for thickness and texture.

Grout Coat: A pigmented epoxy coat to fill the aggregate and create a smooth, sealed surface.

Topcoat (Topfloor): Application of Resutile AT urethane for ultimate abrasion, chemical, and UV resistance.

We provide comprehensive technical support, from specification to on-site guidance, ensuring your contractor or our certified installer team executes flawlessly.

Vanliga frågor och svar (FAQ)

Q: What is the typical installed cost of ResuShield Shop Floor MR?

A: The total project cost depends on slab condition, project size, and preparation required. For an accurate quote tailored to your specific facility, contact us for a detailed assessment. We provide cost-effective solutions that reduce long-term maintenance expense.

Q: Hur lång tid tar installationsprocessen?

A: A typical installation for a medium-sized mechanical room can take 3-5 days, including prep, coating, and cure time. The system allows for a quick return to light foot traffic in 24 hours and full service in 5-7 days.

Q: Can this flooring be applied in a cold warehouse or basement?

A: Application requires ambient and surface temperatures between 60°F and 90°F. For cold conditions, temporary heating is necessary to ensure proper cure and performance. We can advise on project-specific logistics.

Q: How do I clean and maintain this industrial flooring?

A: Maintenance is simple. Regular sweeping and occasional mopping with a neutral pH cleaner are sufficient. Its seamless nature and chemical resistance prevent stains and make deep cleaning easy, protecting your investment for years.

KAIDA PAINT Brand Introduction

Navigating the complex world of industrial flooring requires more than just a product supplier—it demands a knowledgeable partner. KAIDA PAINT specializes in formulating and delivering high-performance resinous flooring systems like ResuShield Shop Floor MR. Our expertise bridges the gap between advanced polymer chemistry and real-world application challenges. We work directly with facility managers, specifiers, and contractors to provide not only premium materials but also the critical technical support, specification guidance, and installation oversight needed for project success. Our commitment is to ensure your flooring investment delivers maximum durability, safety, and value. Let’s discuss your specific project requirements and challenges.

Ready to transform your facility’s floors with confidence? Contact our flooring experts today for a free consultation and project specification.

Trust Built on Proven Results

ResuShield systems are specified by leading companies and applied by professional contractors worldwide for critical infrastructure projects. Our products are manufactured in the USA under strict quality controls and are backed by comprehensive technical data and support. We provide the best combination of product performance and application expertise.

Your Next Step Towards a Superior Floor

Tired of costly floor repairs and safety concerns? Looking for a long-lasting, high-performance solution for your industrial or commercial space?

Contact KAIDA PAINT Today. As a leading manufacturer and solution provider, KAIDA PAINT brings deep expertise in high-performance resinous flooring. We don’t just sell paint or coating; we deliver turnkey solutions. From initial consultation and specification to providing top-tier products and technical support for your chosen contractor, we partner with you to ensure a successful outcome. Our team is ready to help you prepare the perfect specification, answer technical questions, and connect you with certified installers.

Request a quote, download a detailed specification guide, or schedule a consultation with our flooring experts now.