Beskrivning

Produktöversikt

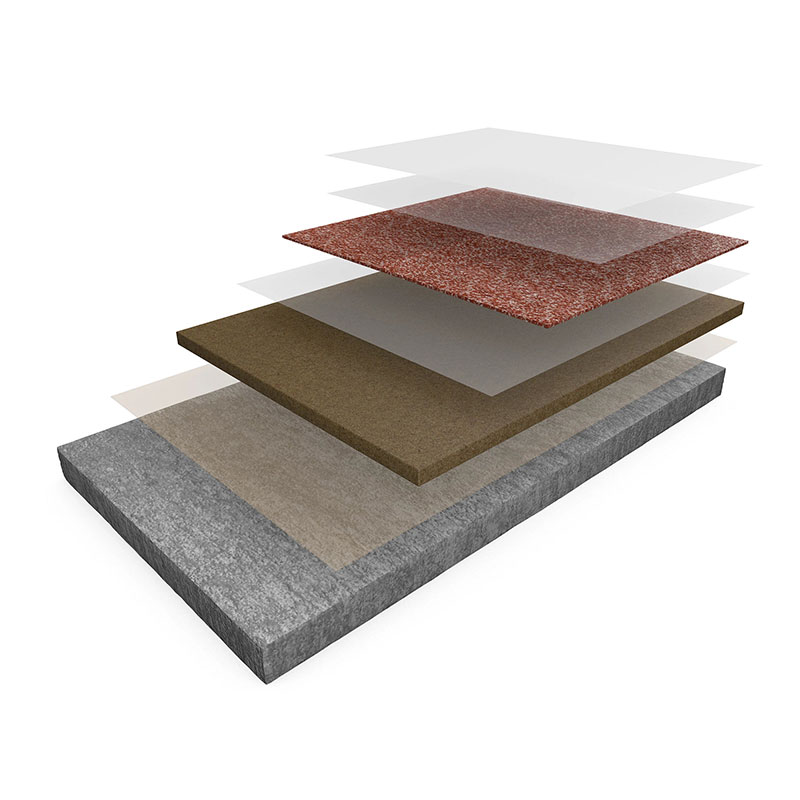

The ResuShield™ Screed Deco Quartz II is a heavy-duty, decorative epoxy flooring system designed for resurfacing interior concrete substrates. This multi-layer system combines a high-strength epoxy and silica sand mortar with beautiful, color-stable quartz aggregates, finished with industrial-grade grout and seal coats. It delivers outstanding protection against impact, abrasion, and chemical exposure while providing an attractive, easy-to-maintain finish. Ideal for environments demanding durability, performance, and aesthetics, this system is the go-to solution for companies and contractors across industrial, commercial, and institutional sectors.

Common Industrial Flooring Problems & How ResuShield™ Solves Them

Traditional floors fail under pressure. Here’s what you might be facing:

Cracks, Spalling, and Dusting: Unsealed or worn concrete creates dust, compromises cleanliness, and leads to progressive damage.

Chemical Attack and Staining: Floors in labs, food processing, or warehouses suffer degradation from oils, acids, and sanitizers.

Heavy Impact and Abrasion Wear: High-traffic areas like warehouse aisles, loading docks, and manufacturing plants experience rapid surface deterioration.

Slippery and Unsanitary Surfaces: Smooth, wet floors in kitchens, bathrooms, and pool decks pose safety risks and harbor bacteria.

Dull, Uninspiring Aesthetics: Outdated floors negatively impact the professional image of showrooms, retail spaces, and corporate offices.

The ResuShield™ Screed Deco Quartz II system directly addresses these pain points with a robust, integrated solution.

Product Solutions & Key Features

The ResuShield™ system isn’t just a coating; it’s a complete performance flooring assembly.

Unmatched Durability & Protection

Exceptional Abrasion Resistance: With a Taber Abrasion loss of only 18 mg (CS-17 wheel, 1000 cycles), this system withstands years of heavy foot and wheeled traffic.

High Load-Bearing Strength: Features a compressive strength of 13,500 psi and tensile strength of 8,000 psi, preventing cracks and damage from heavy equipment.

Superior Adhesion: The system bonds tenaciously to concrete, with adhesion tests resulting in concrete substrate failure (450-732 psi), ensuring long-term integrity.

Impact & Chemical Resistance: Resists degradation from a wide range of industrial chemicals, oils, and cleaners, making it easy to clean and maintain.

Safety, Hygiene & Aesthetics

Slip-Resistant Finishes: Available in a range of textures. The wet static coefficient of friction (SCOF) meets or exceeds safety standards (ANSI/NFSI B101.1), providing slip resistance even when wet.

Seamless, Impervious Surface: The seamless epoxy resin coating prevents dirt, moisture, and bacteria from penetrating the floor, facilitating strict cleaning protocols for hospitals, labs, and food service areas.

Decorative Flexibility: Offers unlimited standard and custom color blends using vibrant, UV-stable quartz aggregates. Choose from gloss or satin finishes to match any design vision.

Efficient Installation & Performance

Proven System Design: A nominal 3/16″ to 1/4″ thick, six-layer system ensures reliable performance. Components include a primer, mortar, broadcast quartz, grout, and durable topcoat.

Low VOC Formulation: Products within the system are designed with low volatile organic compound (VOC) content, supporting better indoor air quality during and after installation.

Tekniska specifikationer & data

The following table summarizes key physical properties of the ResuShield™ Screed Deco Quartz II system, based on independent testing to ASTM standards.

| Fastighet | Testmetod | Resultat / värde |

|---|---|---|

| Motståndskraft mot nötning | ASTM D4060 (CS-17-hjul, 1000 cykler) | 18 mg loss |

| Vidhäftning till betong | ASTM D4541 | 450 psi (concrete failure) |

| Vidhäftning till betong | ASTM D7234 | 732 psi (concrete failure) |

| Hardness, Shore D | ASTM D2240 | 80-85 @ 0 sek / 75-80 @ 15 sek |

| Tensile Strength (Resin) | ASTM D2370 | 8,000 psi |

| Elongation (Resin) | ASTM D2370 | 6% |

| Tryckhållfasthet | ASTM D695 | 13,500 psi |

| Friktionskoefficient (torr) | ASTM D2047 (James maskin) | 0.63 |

| Våt statisk COF | ANSI/NFSI B101.1 (BOT 3000) | 0.94 |

| Brandfarlighet | ASTM D635 | 182 mm/min |

| Water Absorption (24h) | ASTM D570 | 0.2% weight increase |

Idealiska tillämpningar

This versatile system is specified by architects and contractors for demanding environments worldwide:

Healthcare & Pharmaceuticals: Hospitals, clean rooms, labs, biotech facilities.

Kommersiellt och detaljhandel: Supermarkets, showrooms, restaurants, casinos, airports.

Public & Institutional: Schools, universities, stadiums, arenas, auditoriums.

Industri och tillverkning: Warehouses, food & beverage plants, chemical processing areas.

High-Moisture Areas: Locker rooms, showers, bathrooms, pool decks, and laundry facilities.

Professional Installation Process

Optimal performance requires professional installation. The key steps involve:

Surface Preparation & Inspection: Concrete is shot-blasted to a CSP 5 profile (ICRI 310.2R). Moisture testing (ASTM F2170) is critical.

Primer Applicering: ResuShield™ MPE epoxy primer is applied to seal and promote adhesion.

Mortar Bed & Quartz Broadcast: The epoxy mortar (ResuShield™ PT 250) is screeded, followed by an even broadcast of decorative quartz.

Grouting & Sealing: Multiple grout and seal coats (ResuShield™ PT Topcoat, UVE) encapsulate the quartz.

Protective Topcoat: A final coat of ResuShield™ HTS 100 aliphatic urethane provides superior abrasion resistance, UV stability, and a durable finish.

Curing & Protection: The floor must cure under controlled conditions before being opened to traffic.

Vanliga frågor och svar (FAQ)

Q: How does ResuShield™ Screed Deco Quartz II compare to standard epoxy or paint?

A: It is far more robust than a simple epoxy paint or coating. This is a thick, mortar-based system with embedded aggregate, designed for heavy industrial and commercial wear. It offers superior durability, chemical resistance, and longevity.

Q: What is the typical installed cost per square foot?

A: The cost varies based on substrate condition, project size, location, and chosen finish. It is an investment in a long-term solution. For an accurate price, contact us for a project-specific quote.

Q: How long does installation take, and what’s the downtime?

A: A typical installation can take several days depending on area size and conditions. The system can be opened to light traffic in about 24 hours after the final topcoat, with full cure achieved in 7-14 days.

Q: Can it be installed in a basement or over existing tile?

A: It is designed for interior concrete substrates. Proper preparation is key. Existing tile must usually be removed. Basement slabs require rigorous moisture testing first. Consult our technical team for your specific substrate.

Q: Is this a good DIY kit, or do I need a professional contractor?

A: This is a professional-grade system requiring skilled installers with specific equipment and expertise for mixing, application, and finishing. We strongly recommend using our network of certified contractors.

Why Choose KAIDA PAINT for Your Flooring Project?

For over 15 years, KAIDA PAINT has been at the forefront of high-performance resinous flooring solutions. We specialize in the formulation, manufacture, and technical support of advanced epoxy, polyurethane, and hybrid systems for the world’s most challenging environments. Our commitment goes beyond supplying premium products like the ResuShield™ line; we partner with a global network of certified contractors to ensure flawless installation and long-term performance. Whether you’re managing a facility upgrade, specifying for a new construction project, or are a contractor seeking reliable materials and backing, KAIDA PAINT provides the expertise, quality, and support you can count on. Let’s discuss how we can bring durability, safety, and aesthetics to your next project. Reach out to our technical sales team today for a personalized consultation.

At KAIDA PAINT, we are more than just a manufacturer; we are your technical partner in high-performance flooring solutions. With extensive experience in formulating and supplying advanced resinous coatings, we provide:

Expert Technical Support: From specification to installation, our team offers unparalleled guidance.

Kvalitetssäkrade produkter: Consistent, high-quality materials ensure every project’s success.

Global Supply Chain: Reliable supply and support for projects of any scale, anywhere.

Beprövad prestanda: Our systems are trusted in some of the world’s most demanding facilities.

Ready to transform your space with a floor that combines rugged durability with stunning design?

Contact KAIDA PAINT today for a consultation, technical data sheets, or to find a qualified installer near you. Let us provide the best solution for your industrial, commercial, or institutional flooring needs.