Beskrivning

Produktöversikt

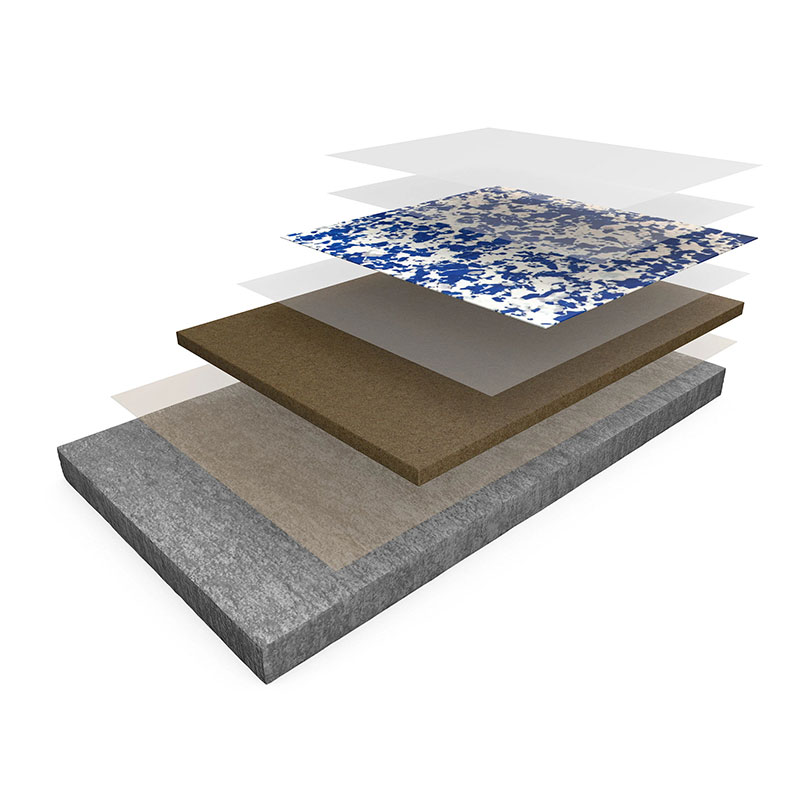

ResuShield™ Screed Deco Flake II is a high-performance, decorative epoxy flooring system designed for demanding commercial, institutional, and industrial interiors. This nominal 1/4-inch thick system combines a heavy-duty epoxy mortar with vibrant, multicolored vinyl flakes, sealed with industrial-grade, UV-resistant coatings. Engineered for superior durability and visual appeal, it revitalizes worn surfaces and protects new concrete substrates against impact, abrasion, and chemical exposure. Companies and contractors choose this system to deliver a long-lasting, sanitary, and attractive flooring solution for high-traffic environments like healthcare facilities, laboratories, retail spaces, and warehouses.

User Pain Points & Application Scenarios

Industrial and commercial floors face constant challenges that compromise safety, cleanliness, and longevity. Common problems include:

Cracking & Damage: Heavy forklift traffic and impact in warehouses and factories cause cracks and spalling in standard concrete.

Dusting & Degradation: Unprotected cement floors create dust, contaminating clean rooms, pharmaceutical facilities, and food processing areas.

Chemical Attack: Spills of oils, solvents, and cleaning agents in automotive shops, laboratories, and industrial kitchens degrade ordinary coatings.

Hygiene & Cleanability: Porous surfaces in hospitals, restaurants, and locker rooms harbor bacteria and are difficult to sanitize effectively.

Aesthetic Wear: High-foot-traffic areas like showrooms, casinos, and airports suffer from stained, dull, and worn-looking floors.

The ResuShield™ system directly addresses these issues, providing a robust shield that extends floor life and reduces maintenance costs.

Solution & Key Features

Our epoxy flooring system offers a comprehensive solution built on exceptional performance characteristics:

Oöverträffad hållbarhet:

Abrasion Resistance: With a Taber Abraser loss of only 18 mg (ASTM D4060), it withstands years of heavy foot and wheeled traffic.

Impact & Crack Resistance: The epoxy mortar formulation offers high compressive strength (10,000+ psi per ASTM C579) and 6% elongation to resist cracking.

Superior Adhesion: Achieves 450-732 psi adhesion (ASTM D4541/D7234), ensuring the system bonds tenaciously to the concrete substrate.

Chemical & Stain Resistance: Formulated to resist a wide range of chemicals, oils, and cleaning solutions, making it ideal for laboratories, food & beverage plants, and automotive facilities. It is easy to clean and maintains a sanitary surface.

Safety & Functionality:

Seamless & Dust-Proof: Creates a monolithic, non-porous surface that eliminates dirt traps and prevents dusting.

Slip-Resistant: The broadcast flake and textured finish provide enhanced slip resistance, even when wet.

UV-Resistant Topcoat: The final seal coat resists yellowing and degradation from sunlight, preserving color and gloss in areas with UV exposure.

Aesthetic Versatility & Customization:

Decorative Flake Blends: Choose from a wide array of standard or custom multicolored vinyl flake blends (1/4″, 1/8″, micro) to achieve the perfect look.

Gloss or Satin Finish: Select the sheen level that matches your design intent, from high-gloss to a more subdued satin.

Color Options: Integral colorants can be added to the mortar and grout coats for a cohesive design.

Professional Installation & Performance: Designed for professional application by approved contractors. The system components—primer, mortar, flake, grout, and sealer—work together for reliable, long-term performance.

Technical Data & Specifications

The following table summarizes key physical properties of the ResuShield™ Screed Deco Flake II system, based on independent testing at 77°F.

| Fastighet | Testmetod | Resultat / värde |

|---|---|---|

| Motståndskraft mot nötning | ASTM D4060 (CS-17-hjul, 1000 cykler) | 18 mg loss |

| Vidhäftning till betong | ASTM D4541 | 450 psi (concrete failure) |

| Vidhäftning till betong | ASTM D7234 | 732 psi (concrete failure) |

| Hardness, Shore D | ASTM D2240 | 80-85 @ 0 sec | 75-80 @ 15 sec |

| Tensile Strength (Resin) | ASTM D2370 | 8,000 psi |

| Elongation (Resin) | ASTM D2370 | 6% |

| Tryckhållfasthet | ASTM C579 | 10,000 psi |

| Brandfarlighet | ASTM D635 | 182 mm/min |

| VOC-innehåll | ASTM D3960 | <50 g/L (System Components) |

Idealiska tillämpningar

This versatile flooring solution is specified by architects and facility managers for numerous demanding environments:

Healthcare & Institutions: Hospitals, clinics, labs, clean rooms, schools, universities.

Kommersiellt och detaljhandel: Supermarkets, showrooms, restaurants, casinos, arenas, airports.

Industri och tillverkning: Pharmaceutical/Biotech facilities, food & beverage plants, warehouses, logistics centers.

Public & Recreational: Locker rooms, restrooms, stadiums, auditoriums, municipal buildings.

Professional Installation Process

A successful, long-lasting floor requires proper installation by qualified professionals. The key steps include:

Surface Preparation & Repair: Concrete is abrasive-blasted (CSP 3-5 profile) to remove contaminants and laitance. Cracks and voids are filled.

Primer Applicering: A coat of epoxy primer is applied to seal the substrate and promote adhesion.

Mortar Screed & Flake Broadcast: The epoxy mortar is screeded to the desired thickness (3/16″ or 1/4″). Colored vinyl flakes are immediately broadcast into the wet surface.

Grouting & Sealing: After curing, excess flake is removed, and a grout coat is applied to fill voids. A final, durable UV-resistant seal coat (gloss or satin) is applied to protect the system and enhance its appearance.

Curing & Traffic: The system requires proper cure time before accepting light and full traffic.

Vanliga frågor och svar (FAQ)

Q: How does the ResuShield™ flake system compare to epoxy paint or tile?

A: Unlike thin epoxy paint, this is a 1/4″ thick mortar system offering far greater impact resistance and longevity. Compared to tile, it provides a seamless, grout-free surface that is more hygienic and resistant to heavy loads.

Q: What is the typical installed cost per square foot?

A: The final cost depends on substrate condition, project size, flake selection, and geographic location. For a commercial-grade, professionally installed system, contact us for a detailed quote tailored to your specific project.

Q: How long does installation take, and when can we use the floor?

A: Application time varies with area size and conditions. The floor can typically accept light foot traffic in 24-48 hours after the final coat, with full cure and ability to withstand heavy equipment achieved within 5-7 days.

Q: Is this a DIY flooring kit?

A: No. This is a professional-grade system requiring specialized equipment, materials handling, and expertise for proper installation and performance. It must be installed by approved, experienced contractors.

Q: How do I clean and maintain this flooring?

A: Daily sweeping and occasional damp mopping with neutral pH cleaners are sufficient. Avoid harsh acids or abrasive pads. For specific chemical spills, refer to the maintenance guide.

Trust & Proven Performance

ResuShield™ systems are manufactured to the highest standards. Our products are trusted by leading companies across various industries for critical flooring applications. We provide comprehensive technical support, from initial specification through project completion, ensuring a successful result.

Är du redo att förändra ditt golv?

If you’re a contractor bidding on a project, a facility manager planning an upgrade, or an architect specifying materials, we are your partner for high-performance flooring solutions.

About KAIDA PAINT

KAIDA PAINT is a leading manufacturer and solution provider of advanced industrial coatings and resinous flooring systems. We combine high-quality products like the ResuShield™ line with deep technical expertise and project support. Our team works directly with contractors and end-users to deliver flooring solutions that meet exacting performance, aesthetic, and budgetary requirements. From product selection and system design to on-site application guidance, we ensure your flooring investment delivers lasting value.

Contact us today for product data sheets, a system sample, a detailed quote, or to consult with our technical specialists about your specific flooring challenge.