Beskrivning

Produktöversikt

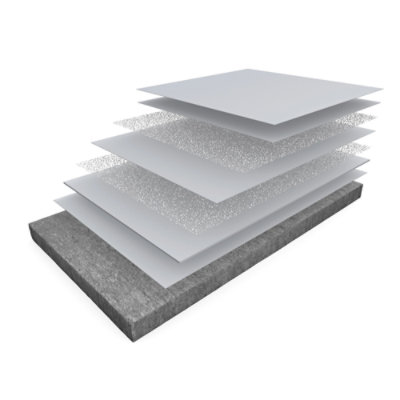

TerraFlex™ AB is a 100% solids, low-odor, solid-color quartz broadcast, hybrid flooring system. It consists of a cementitious urethane base coat with low-odor epoxy and fast-curing aliphatic urethane topcoats for a high-gloss finish. This self-priming system has a nominal thickness of 3/16 – 1/4 inch. Quick-curing technology allows for faster installations in demanding environments like healthcare, manufacturing, and pharmaceutical facilities.

Understanding the Challenges of Industrial Flooring

Traditional concrete floors, epoxy coating, and even some urethane systems can fail under intense pressure. Common pain points for facility managers and contractors include:

Cracking and Impact Damage: Forklifts, dropped tools, and heavy rolling loads cause cracks in brittle floors, leading to costly repairs and downtime.

Chemical Attack and Staining: Spills from oils, acids, solvents, and cleaning agents degrade floor surfaces, compromising safety and cleanliness.

Dusting and Degradation: Constant abrasion creates dust, contaminating products and machinery, especially critical in food, pharma, and electronics companies.

Moisture and Vapor Issues: Hydrostatic pressure and vapor transmission from slabs can cause blistering and delamination of many flooring products.

Difficult and Lengthy Installation: Extended cure times disrupt operations, while complex installation requirements increase labor cost.

The TerraFlex™ AB Solution: Unmatched Performance and Durability

TerraFlex™ AB is a hybrid, 100% solids system designed as a comprehensive solution. Its multi-layer construction ensures each functional need is addressed.

Core System Advantages:

Superior Mechanical Strength: The cementitious urethane base provides exceptional compressive strength (exceeding 9,000 psi) and impact resistance (>160 in-lbs), preventing cracks from propagating from the concrete substrate.

Exceptional Chemical & Abrasion Resistance: The seamless, non-porous finish from the fast-curing aliphatic polyurethane topcoat resists a wide range of industrial chemicals and offers outstanding abrasion resistance (27 mg loss, ASTM D4060), ensuring long-term durability.

Moisture Tolerance: Unlike many systems, TerraFlex™ AB can be installed on substrates with up to 99% relative humidity (ASTM F2170) and mitigates vapor drive issues, expanding its application range.

Hygienic & Easy Clean Surface: The seamless, monolithic coating eliminates grout lines and pores where bacteria can hide. It is easily cleaned and meets USDA/FDA requirements for sanitary environments.

Rapid Return-to-Service: The system features quick-cure topcoats, allowing for faster installation timelines and minimizing facility disruption.

Technical Specifications & Performance Data

The performance of TerraFlex™ AB is verified by independent testing against recognized international standards.

| Fastighet | Testmetod | Typical Value |

|---|---|---|

| Systemets tjocklek | Nominal | 3/16″ – 1/4″ (4.8 – 6.4 mm) |

| Tryckhållfasthet | ASTM C579 | > 9,000 psi (Base Coat) |

| Draghållfasthet | ASTM D638 | > 2,175 psi (Base Coat) |

| Motståndskraft mot nötning | ASTM D4060 | 27 mg loss (Topcoat) |

| Bond Strength to Concrete | ASTM D4541 | > 400 psi (Substrate failure) |

| Hårdhet (Shore D) | ASTM D2240 | 70 (Topcoat) |

| VOC-innehåll | - | 0 g/L (100% Solids) |

| Slip Resistance (Wet) | ANSI A326.3 | >0.42 Dynamic Coefficient of Friction |

Ideal Applications for TerraFlex™ AB

This versatile cementitious urethane flooring system is specified by leading companies and contractors across diverse sectors:

Bearbetning av livsmedel och drycker: Withstands caustic cleaners, thermal shock, and provides a USDA-compliant, easy-to-clean surface.

Pharmaceutical & Life Sciences: Meets cGMP demands for seamless, chemical-resistant, and non-shedding floors.

Automotive & Manufacturing: Resists hydraulic fluids, fuels, and extreme impact from heavy machinery and parts.

Lagerhållning och logistik: Handles relentless abrasion from pallet jacks and forklift traffic without wearing thin.

Commercial & Institutional: Provides a durable, attractive, and low-maintenance finish for schools, hospitals, and municipal buildings.

Professionell installation och support

A successful floor depends on proper installation. The TerraFlex™ AB system follows a proven sequence:

Förberedelse av ytan: Mechanical shot blasting to a CSP 3-4 profile is critical for optimal adhesion.

Fuktprovning: RH probes (ASTM F2170) ensure substrate conditions are within specification.

Base Coat & Broadcast: The cementitious urethane mortar is applied self-leveling and broadcast with flint quartz for texture and thickness.

Broadcast Coat: An epoxy resin coat is applied and broadcast with more quartz for density.

Grout & Topcoat: A pigmented, fast-curing polyurethane sealer is applied in one or two coats to create the final chemical-resistant, high-gloss wear layer.

Our Technical Partnership: We provide more than just products. Our team offers pre-installation consultation, jobsite evaluation, detailed specification support, and on-site guidance for certified contractors to ensure flawless execution.

Vanliga frågor och svar (FAQ)

How is a cementitious urethane system different from epoxy flooring?

Cementitious urethane systems like TerraFlex™ AB combine a mortar base for load-bearing strength with a polyurethane top for chemical and abrasion resistance. They are generally more flexible, have better thermal shock resistance, and can tolerate higher moisture levels in the concrete substrate compared to many epoxy systems.

What is the typical installed cost of TerraFlex™ AB?

The total cost varies based on substrate condition, project size, location, and preparation requirements. As a premium, high-performance system, it represents a long-term investment in durability and reduced maintenance. Contact us for a project-specific quote.

How long does the installation process take?

While surface prep and cure times are critical, the quick-curing topcoats in the TerraFlex™ AB system allow for a faster return-to-service than many alternatives. A typical installation can be completed in phases over several days, depending on area size and conditions.

Can TerraFlex™ AB be applied over an existing painted concrete floor?

All existing paint, coatings, and sealers must be completely removed via mechanical preparation (shot blasting/grinding) to expose a clean, sound, and profiled concrete substrate. This is essential for the cementitious urethane mortar to achieve a proper mechanical bond.

Proven Performance Across Industries

Leading manufacturing companies, global logistics firms, and top-tier pharmaceutical facilities trust high-performance resinous flooring for their critical assets. Our portfolio includes successful installations in Fortune 500 plants and stringent cleanroom environments. We hold and provide technical data sheets, SDS, and performance guides that verify our claims.

KAIDA PAINT Brand Introduction in English

About KAIDA PAINT in the Industrial Flooring Sector & the Advantage of TerraFlex™ AB:

KAIDA PAINT is a leading manufacturer and solutions partner specializing in high-performance industrial coatings. Within the industrial flooring arena, we have a deep understanding of the ultimate challenges floor surfaces face in demanding environments—from heavy impact and chemical corrosion to stringent hygiene standards. This insight is the driving force behind our development of advanced systems like TerraFlex™ AB.

Our strength lies in combining profound materials science expertise with real-world application challenges. KAIDA PAINT delivers more than just premium coating products; we provide a complete solution framework:

Innovative Formulation: TerraFlex™ AB utilizes our proprietary hybridization technology, blending polyurethane resilience with cementitious fortitude to achieve the perfect balance of flexibility and load-bearing strength, chemical resistance, and durability.

Full-Cycle Support: We ensure system performance translates flawlessly from the lab to the jobsite. Our support spans free pre-project substrate evaluation and specification design, to detailed installation training and on-site guidance for certified applicators and contractors.

Quality Commitment: We maintain stringent control over raw materials and finished goods, guaranteeing consistent batch-to-batch performance that meets relevant international standards, providing long-term protection for your flooring asset.

Choosing KAIDA PAINT and TerraFlex™ AB means investing in more than just a coating; it is a commitment to a long-term performance guarantee backed by professional analysis, reliable products, and continuous support. We partner with companies across sectors to reduce total cost of ownership and enhance operational efficiency.

Is your facility facing similar challenges?

Contact our expert team today for a free technical consultation and a tailored solution for your project needs. Let us help you build a stronger, safer, and more productive space.