Descrizione

Panoramica del prodotto

TerraFlex™ ES is a premium cementitious urethane flooring system engineered for the most demanding industrial and commercial environments. It’s a seamless, high-performance coating that combines the chemical resistance of polyurethane with the mechanical toughness of a cement-modified mortar, creating an incredibly durable hybrid finish. This system offers exceptional impact resistance, superior abrasion performance, and excellent resistance to thermal shock, providing a long-lasting solution for factories, warehouses, laboratories, and food processing facilities. For companies and facility managers seeking a reliable flooring option that withstands heavy traffic, chemical exposure, and extreme temperature fluctuations, TerraFlex™ ES delivers a proven industrial-grade solution.

The Industrial Flooring Challenge: Common Pain Points

Industrial and commercial floors face relentless challenges that standard concrete or epoxy systems often can’t withstand:

Cracking and Impact Damage: Forklifts, dropped tools, and heavy equipment cause cracks, chips, and spalling in brittle floors.

Chemical Corrosion and Staining: Oils, greases, solvents, acids, and cleaning agents degrade floor surfaces, leading to failure and unsightly stains.

Abrasion and Wear: Constant foot and wheel traffic creates dust, wears down surfaces, and necessitates frequent repairs.

Moisture and Hygienic Concerns: Moisture vapor transmission (MVT) can blister coatings, while porous surfaces harbor bacteria, making cleaning difficult in food and pharmaceutical settings.

Downtime and High Maintenance Costs: Frequent repairs and recoating lead to operational disruptions and escalating long-term expenses.

These are the critical problems that contractors and facility owners aim to solve with a superior flooring installation.

The TerraFlex™ ES Solution: Engineered for Performance

TerraFlex™ ES isn’t just a paint or a simple coating; it’s a complete, integrated system designed to directly address these industrial challenges.

1. Unmatched Mechanical Durability

Extreme Abrasion Resistance: Formulated with a high-performance urethane top layer and a cementitious base, it offers far greater wear life than standard epoxy or concrete sealers. Ideal for high-traffic aisles and loading docks.

Superior Impact & Thermal Shock Resistance: The hybrid urethane and mortar matrix absorbs impacts and withstands rapid temperature changes without cracking, a common failure point for rigid systems.

Seamless, Monolithic Finish: Creates a joint-free surface that eliminates trip hazards and prevents dirt and moisture ingress, simplifying sanitation.

2. Exceptional Chemical & Environmental Resistance

Broad Chemical Resistance: Highly resistant to a wide range of oils, greases, diluted acids, alkalis, and salts, protecting the concrete substrate below.

Moisture-Tolerant: Can be applied to substrates with higher moisture levels than typical epoxy systems, thanks to its cementitious urethane chemistry.

Stabilità termica: Performs consistently across a wide temperature range, maintaining flexibility in cold and stability in heat.

3. Safety, Hygiene & Ease of Maintenance

Customizable Slip Resistance: Can be integrally broadcast with aggregates to achieve desired slip ratings (R9-R11) for safety in wet areas.

Non-Porous, Easy-Clean Surface: The dense, seamless finish prevents bacteria growth and allows for quick, effective wash-down, meeting high hygiene standards.

Low VOC & Food-Safe Options: Available in low-odor, food-contact compliant formulations suitable for sensitive environments.

4. Aesthetic Versatility & Long-Term Value

Color & Finish Options: Available in a wide spectrum of colors with gloss, semi-gloss, or satin finish to meet aesthetic and functional lighting needs.

Reduced Lifecycle Cost: While the initial cost may be higher than basic paint, its extreme durability drastically reduces maintenance, repair, and recoating frequency, offering a superior return on investment.

Specifiche tecniche e dati sulle prestazioni

The following table outlines the key performance characteristics of the TerraFlex™ ES cementitious urethane flooring system, verified through standardized testing.

| Proprietà | Metodo di prova | Typical Value / Performance |

|---|---|---|

| System Type | – | 100% Solids, Cement-Modified Polyurethane |

| Resistenza alla compressione | ASTM C579 | > 10,000 psi |

| Resistenza alla flessione | ASTM D790 | > 6,000 psi |

| Resistenza alla trazione | ASTM D638 | > 3,500 psi |

| Durezza | ASTM D2240 (Shore D) | 75 – 80 |

| Resistenza all'abrasione | ASTM D4060 (CS-17 Wheel) | < 50 mg loss (Excellent) |

| Bond Strength to Concrete | ASTM D4541 | > 450 psi (Substrate Failure) |

| Resistenza chimica | ASTM D1308 / D543 | Excellent to Oils, Greases, Dilute Acids & Alkalis |

| Resistenza agli shock termici | Proprietary Cycle Test | No cracking after cycles from -40°F to 180°F |

| Slip Resistance (Wet) | DIN 51130 | Configurable to R9, R10, R11 |

| Contenuto di VOC | EPA Method 24 | < 100 g/L (Low VOC options available) |

Ideal Application Areas

TerraFlex™ ES is the specified choice across numerous industries where floor performance is critical:

Lavorazione di alimenti e bevande: Withstands thermal shock from washdowns, resists acids/sugars, and provides a cleanable, USDA-compliant surface.

Pharmaceutical & Biotechnology: Creates seamless, cleanroom-suitable floors that are chemical-resistant and easy to sanitize.

Warehousing & Logistics: Handles extreme abrasion from pallet jacks and forklifts without wearing through.

Automotive & Manufacturing: Resists hydraulic fluids, oils, and impact from dropped parts and equipment.

Commercial Kitchens & Breweries: Manages heat, moisture, grease, and constant cleaning.

Parcheggi: Provides a durable, salt- and weather-resistant coating for vehicular traffic decks.

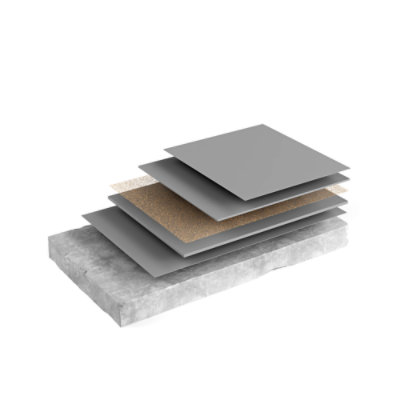

Professional Installation Process

A successful, long-lasting installation requires expert preparation and application. Key steps include:

Substrate Evaluation & Preparation: Critical inspection for moisture, cracks, and strength. Surface is mechanically prepared (e.g., shot blasting) to a concrete surface profile (CSP) of 3-4 to ensure optimal adhesion.

Primer Application: A specialized primer is applied to penetrate and seal the concrete, creating a perfect bonding bridge.

Cementitious Urethane Mortar Installation: The core cementitious urethane mortar layer is trowel- or pump-applied to the desired thickness (typically 1/4″ to 1/2″), creating a smooth, level substrate.

Polyurethane Topcoat Sealing: One or more coats of high-performance polyurethane or urethane sealer are applied. This final layer provides the ultimate chemical, abrasion, and UV resistance, and determines the final color and gloss finish.

Curing & Commissioning: The system cures fully within days, ready for light traffic, with full chemical resistance achieved within 7 days.

Partner with Expert Contractors: The performance of any high-end flooring system depends on proper installation. We strongly recommend working with our network of certified, experienced contractors who are trained in the specifics of cementitious urethane systems.

Domande frequenti (FAQ)

Q: What is the main difference between a cementitious urethane floor and an epoxy floor?

A: The key difference is in performance under stress. Cementitious urethane systems like TerraFlex™ ES are more flexible and elastic, offering far superior resistance to thermal shock, impact, and abrasion. Epoxy systems are typically harder but more brittle, making them more prone to cracking under these conditions. Urethane also generally offers better UV stability and chemical resistance.

Q: Can TerraFlex™ ES be installed over existing concrete?

A: Yes, it is an excellent solution for renovating old, worn concrete floors. The substrate must be properly prepared, sound, and evaluated for moisture. The system can also be applied over properly prepared existing flooring products in some cases.

Q: How long does the installation process take?

A: Timeline depends on area size, substrate condition, and system thickness. Typically, for a 10,000 sq. ft. area, complete installation including prep, application, and curing may take 5-7 days. Critical factors like moisture mitigation can affect this.

Q: What is the typical cost range for a cementitious urethane flooring system?

A: The cost varies based on project size, substrate condition, desired thickness, and geographic location. As a premium, long-life system, it represents a higher initial investment than basic coatings but a significantly lower total lifecycle cost. Contact us for a project-specific quote.

Q: How do I maintain a TerraFlex™ ES floor?

A: Maintenance is simple. Regular sweeping and occasional damp mopping with a neutral pH cleaner are usually sufficient. Avoid harsh abrasives and strong acidic cleaners. The seamless nature prevents dirt entrapment, making cleaning efficient.

Proven Performance & Trust

TerraFlex™ ES is trusted by leading companies in manufacturing, logistics, and food processing. Our products are backed by:

Detailed Case Studies: See before-and-after pictures and read about performance in real-world settings like automotive plants and cold storage warehouses.

Technical Data & Certifications: Supported by comprehensive test data from independent laboratories.

Expert Support: From specification through installation, our technical team provides unparalleled support to ensure project success.

Take the Next Step with Kaida Paint

For over two decades, Kaida Paint has been at the forefront of developing advanced protective coatings and flooring systems for industry. We move beyond simply supplying products; we deliver comprehensive solutions built on a foundation of material science and practical application knowledge.

Our flagship TerraFlex™ ES cementitious urethane system embodies this philosophy. It was developed in direct response to the limitations of traditional epoxy and concrete sealer options, offering facility managers and contractors a genuinely superior alternative where performance cannot be compromised.

Why Choose Kaida Paint for Your TerraFlex™ ES Project?

Deep Technical Expertise: Our chemists and engineers specialize in hybrid cementitious urethane systems, offering you not just a product, but a scientifically formulated solution.

End-to-End Project Support: We work directly with facility managers, specifiers, and contractors, providing site assessments, detailed specifications, and on-site technical guidance throughout the installation.

Quality & Consistency: We control the manufacturing of our products to ensure every batch of TerraFlex™ ES meets our rigorous performance standards, giving you peace of mind.

Proven Results for Industry Leaders: Our systems are specified by major companies who cannot afford floor failure, from global logistics firms to precision manufacturers.

Ready to transform your industrial floor into a durable, low-maintenance asset?

Contact Kaida Paint today for:

A complimentary project consultation and site evaluation.

Detailed technical data sheets and material samples.

A quote tailored to your specific area and requirements.

A referral to a certified, experienced installation contractor in your region.

Let’s build a floor that’s as tough as your business.