Descrizione

Panoramica del prodotto

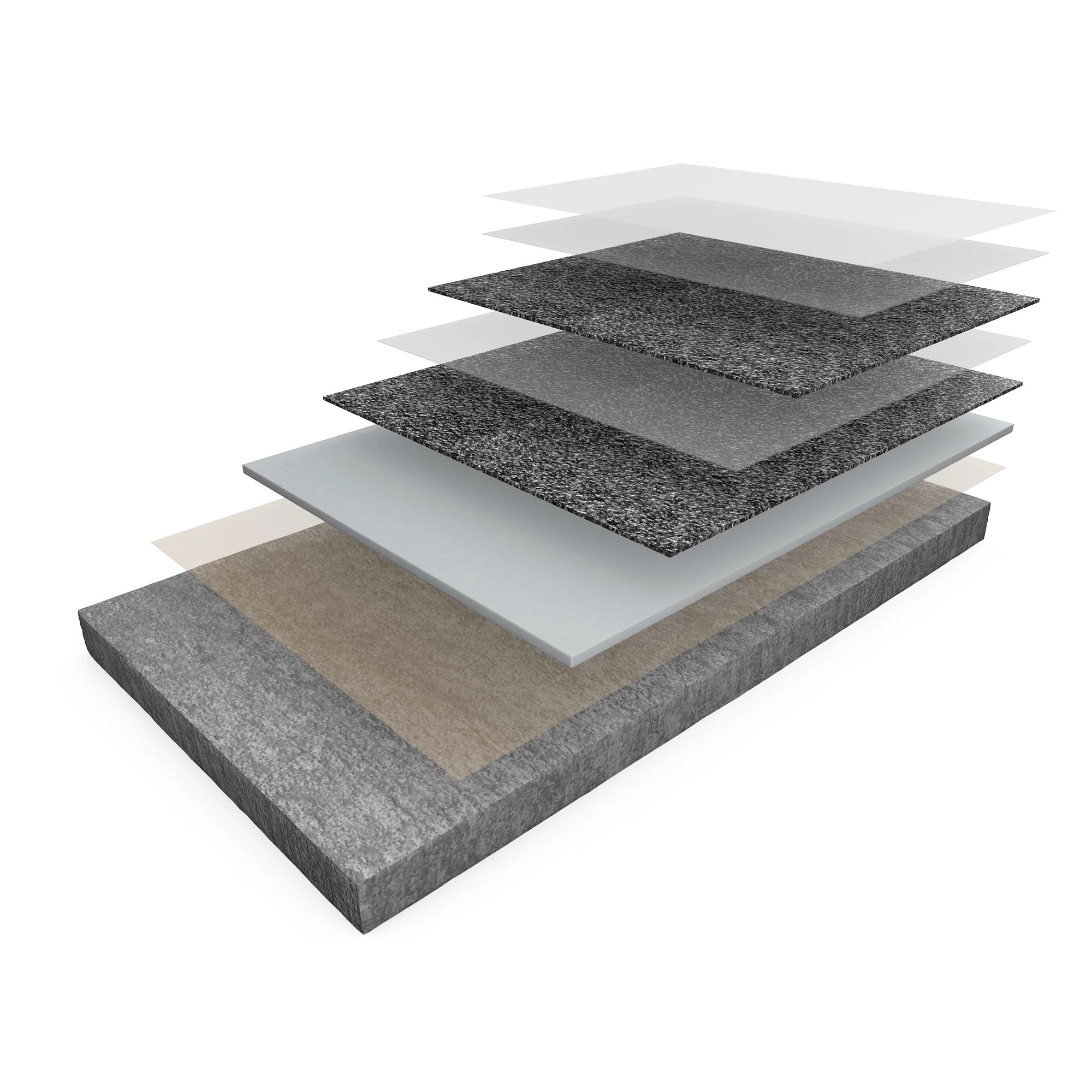

TerraFlex™ AQ is a seamless, 1/4-inch thick decorative quartz floor system designed for high-traffic commercial and industrial spaces. By combining a moisture-tolerant, self-priming cementitious urethane base coat with decorative quartz aggregates and a durable aliphatic topcoat, it forms a robust, monolithic system. It offers exceptional abrasion resistance, chemical tolerance, and a non-slip finish. This coating provides a hygienic, easy-to-clean, and aesthetically versatile solution for facilities like laboratories, food processing plants, and warehouses.

User Pain Points & Scenario Analysis

Industrial and commercial concrete flooring faces relentless challenges. Facility managers and contractors frequently grapple with:

Cracking & Impact Damage: Heavy forklift traffic and dropped tools can crack brittle coatings.

Dusting & Degradation: Constant abrasion wears down surfaces, creating dust that contaminates products and processes.

Attacco chimico: Spills from oils, solvents, acids, and cleaning agents can degrade standard epoxy flooring.

Moisture Problems: Hydrostatic pressure and vapor transmission lead to blistering and delamination.

Hygiene & Cleanliness: Porous or cracked floors harbor bacteria, making sanitation difficult in food, pharmaceutical, or healthcare settings.

Aesthetic Deterioration: Stains, tire marks, and fading detract from a professional appearance in retail or lobby areas.

Specific Scenarios:

Food & Beverage Plant: Needs a seamless, chemical-resistant finish that withstands daily washdowns with acidic cleaners and prevents bacterial growth.

Logistics Warehouse: Requires an ultra-durable urethane mortar system that resists constant abrasion from wheeled traffic and heavy point loads without cracking.

Commercial Parking Garage: Demands a coating with excellent UV stability, thermal shock resistance, and a safe, textured finish for wet conditions.

Product Solution & Detailed Features

TerraFlex™ AQ is engineered to directly solve these pain points. Its cementitious urethane chemistry delivers a unique set of advantages:

Core Benefits & Features:

Unmatched Durability: A hybrid mortar system offering superior tensile and flexural strength compared to standard epoxies, effectively resisting cracks from substrate movement.

Exceptional Chemical Resistance: The polyurethane topcoat provides broad resistance to a wide range of chemicals, including oils, greases, dilute acids, and alkalis, protecting your concrete substrate.

Moisture Tolerance: Can be installed on substrates with high moisture levels (up to 99% RH), mitigating the risk of failure due to vapor transmission—a critical advantage over many epoxy systems.

Senza cuciture e igienico: The fluid-applied system creates a joint-free surface with no pores for dirt, moisture, or bacteria to accumulate, simplifying cleaning and meeting high sanitation standards.

Safety-Enhanced Finish: Available with selected quartz aggregates to provide a permanent, slip-resistant texture, enhancing safety even when wet.

Decorative Versatility: Choose from a wide palette of standard and custom quartz blend colors to achieve both aesthetic goals and functional slip resistance.

Fast Return-to-Service: The system features rapid cure times, minimizing facility downtime during installation.

Technical Parameters & Authoritative Data

The performance of TerraFlex™ AQ is verified by standardized testing methods, ensuring reliability for companies and specifiers.

| Proprietà | Metodo di prova | Typical Result |

|---|---|---|

| System Thickness | Nominal | 1/4 inch (6 mm) |

| Resistenza alla compressione | ASTM C 579 | > 9,000 psi |

| Resistenza alla trazione | ASTM D 638 | > 2,100 psi |

| Resistenza all'abrasione | ASTM D 4060 (CS-10) | < 30 mg loss |

| Bond Strength to Concrete | ASTM D 4541 | 400 psi (substrate failure) |

| Resistenza chimica | - | Excellent vs. oils, greases, dilute acids/bases |

| Resistenza allo scivolamento (bagnato) | ANSI A326.3 | > 0.42 Dynamic Coefficient of Friction |

| Contenuto di VOC | - | 0 g/L (varies by component) |

| Pot Life (@ 70°F) | - | 20-30 minutes (varies by component) |

Aree di applicazione

TerraFlex™ AQ is the ideal flooring choice for any environment demanding durability, cleanliness, and performance.

Healthcare & Pharma: Hospitals, cleanrooms, laboratories. Value: Seamlessness, chemical resistance, ease of sterilization.

Cibo e bevande: Processing plants, kitchens, breweries. Value: USDA/FDA compliance, chemical resistance, seamless hygiene.

Commerciale e al dettaglio: Supermarkets, schools, airport lobbies, showrooms. Value: Aesthetic appeal, durability, safety.

Industrial & Logistics: Manufacturing plants, automotive shops, distribution warehouses. Value: Extreme abrasion/impact resistance.

Institutional: Schools, universities, public works facilities. Value: Long lifecycle, low maintenance cost.

Installation Process & Technical Support

A successful installation is key to performance. TerraFlex™ AQ requires professional application by trained contractors.

Key Installation Steps:

Preparazione della superficie: Concrete must be clean, sound, dry, and shot-blasted to a CSP 3-4 profile.

Primer (if required): Application of a moisture-mitigating primer on porous substrates.

Basecoat & 1st Broadcast: The cementitious urethane basecoat is applied, immediately followed by a broadcast of decorative quartz aggregate.

Second Broadcast Coat: A resin coat is applied and a second quartz broadcast is embedded.

Grout & Topcoat: The system is sealed with Accelera grout and topcoat, providing chemical resistance and the final finish.

Our Support: KAIDA PAINT doesn’t just supply products; we partner with you. We offer:

Pre-Installation Consultation: Site evaluation and moisture testing guidance.

Detailed Specifications: Provide master spec sheets and pictures of application details.

On-Site Technical Support: Available to assist your contracting team during critical application phases.

Domande frequenti (FAQ)

What is the difference between a cementitious urethane and an epoxy flooring system?

Cementitious urethane systems like TerraFlex™ AQ combine cementitious fillers with polyurethane resins, offering superior flexibility, thermal shock resistance, and moisture tolerance. Epoxy systems are typically more rigid and can be brittle, making them less suitable for environments with temperature fluctuations or active cracks.

How long does the TerraFlex™ AQ installation process take?

The timeline depends on area size and conditions. Typically, after surface prep, the multilayer system application can be completed over 2-3 days, with full cure and return to heavy service in approximately 5-7 days at 70°F.

What maintenance does a cementitious urethane floor require?

Maintenance is simple. Regular sweeping and occasional wet mopping with neutral pH cleaners are usually sufficient. Avoid harsh acidic or solvent-based cleaners. The durable topcoat acts as a sealer, protecting the aggregate beneath.

Can TerraFlex™ AQ be applied over existing coated concrete?

It can be applied over some existing coatings, but this requires rigorous assessment and mechanical preparation (e.g., shot blasting) to ensure proper adhesion. A primer may be necessary. A site evaluation is always recommended.

Social Proof & Trust Building

Case Studies: Successfully installed in numerous FDA-regulated pharmaceutical facilities and major food processing companies across North America, with documented performance over 5+ years.

Certifications & Compliance: System components are 100% solids, low odor, and comply with stringent indoor air quality standards (e.g., CA Section 01350). They are formulated for use in USDA and FDA inspected facilities.

Industry Partnerships: KAIDA PAINT products are specified and applied by a network of certified, experienced flooring contractors trusted by leading industrial and commercial enterprises.

Partner with KAIDA PAINT for Your Next Flooring Project

KAIDA PAINT is a leading manufacturer and solution provider of high-performance industrial coatings. We specialize in formulating and supporting advanced systems like TerraFlex™ AQ, partnering with professional contractors to ensure flawless execution. Our advantage lies in our deep technical expertise, responsive support, and commitment to delivering flooring solutions that last.

Ready to transform your concrete floor?

Contact our flooring specialists today for a detailed quote, technical data sheets, or to connect with a qualified installer in your area. Let us help you specify the right system for your performance needs and budget.