Descrizione

Panoramica del prodotto

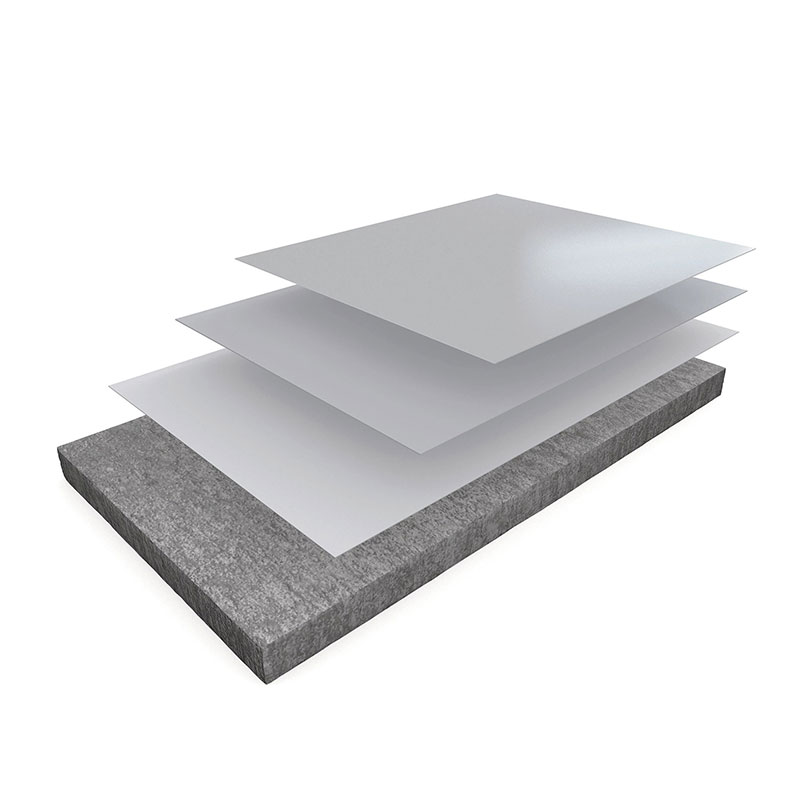

The ResuShield™ Gard SL is a high-build, self-leveling epoxy flooring system designed for demanding industrial and commercial environments. This seamless, resin-rich coating combines a durable epoxy base with a chemical-resistant urethane topcoat to form a monolithic, protective layer over concrete substrates. It delivers exceptional abrasion resistance, impact strength, and seamless hygiene, making it an ideal solution for facilities that require a durable, easy-to-clean, and long-lasting floor finish. The ResuShield™ Gard SL system provides a reliable, high-performance flooring solution for warehouses, manufacturing plants, food processing facilities, and other high-traffic areas.

The Problem with Traditional Industrial Flooring

Industrial floors face relentless daily abuse. Traditional options like plain concrete or thin coatings often fail, leading to costly downtime, safety hazards, and frequent repairs. Common pain points for facility managers and contractors include:

Dusting and Degradation: Untreated or poorly coated concrete generates dust, contaminating products and machinery, and compromising air quality.

Cracks and Spalling: Heavy loads and impact cause cracks, which spread and undermine the structural integrity of the flooring.

Attacco chimico: Spills from oils, solvents, and acids in industrial settings can penetrate and degrade standard paint or sealer.

Difficult Cleaning: Porous surfaces trap dirt, grease, and bacteria, making cleaning labor-intensive and failing sanitation audits in food or pharmaceutical companies.

Durata di vita breve: Frequent recoating and repair drive up the total cost of ownership.

The ResuShield™ Gard SL system is engineered to address these exact challenges.

ResuShield™ Gard SL: Your Complete Flooring Solution

This isn’t just a coating; it’s a complete flooring system. Here’s what makes it the best choice for your business:

1. Unmatched Durability & Performance

Estrema resistenza all'abrasione: Withstands the constant traffic of forklifts, heavy carts, and foot traffic without wearing thin.

Alta resistenza agli urti: Absorbs heavy blows from dropped tools or equipment, preventing cracks and chips in the concrete below.

Seamless & Monolithic: No grout lines or seams to harbor dirt, moisture, or bacteria. Creates a truly hygienic surface that is easy to clean and dry.

100% Solids, High-Build: Applied at a nominal 100 mils thickness, it provides a substantial protective layer that bridges minor substrate imperfections.

2. Superior Chemical & Stain Resistance

The epoxy resin basecoat and durable urethane topcoat provide a barrier against a wide range of chemicals commonly found in industrial and commercial settings, including oils, greases, dilute acids, and alkalis. This makes it perfect for warehouse, automotive, and food processing applications.

3. Enhanced Safety & Cleanliness

Slip-Resistant Options: Available in different finish textures, including options with added grit for slip resistance in wet areas like kitchens or bathrooms.

Easy to Clean & Maintain: The non-porous, glossy top surface allows for quick spill cleanup. Daily sweeping and occasional damp mopping are typically all that’s needed.

FDA/USDA Compliant: The system meets relevant regulatory requirements for incidental food contact, supporting sanitation protocols.

4. Aesthetic Versatility & Professional Finish

Custom Colors: Available in a range of standard and custom colors (gray, white, etc.) to match your facility’s design or color-coding needs.

Smooth, Self-Leveling Finish: Provides a sleek, professional appearance that enhances the overall look of any room or warehouse.

Gloss or Satin Sheen: Choose the sheen level that fits your aesthetic and lighting requirements.

Technical Specifications & Data

| Parametro | Metodo di prova | Specification/Performance |

|---|---|---|

| System Thickness | Nominal | 100 mils (0.1 inch) |

| Resistenza alla compressione | ASTM D695 | 16,000 psi |

| Resistenza alla trazione | ASTM D638 | 3,000 psi |

| Resistenza all'abrasione | ASTM D4060 (ruota CS-17) | ≤ 35 mg loss |

| Resistenza chimica | 7-Day Exposure | Excellent resistance to water, oils, greases, dilute acids & alkalis |

| Flame Spread | ASTM E84 | Classe A |

| Contenuto di VOC | – | 0 g/L (Topcoat & Base) |

| Pot Life (Base) | @ 70°F | 20-25 minuti |

Aree di applicazione ideali

The ResuShield™ Gard SL system is the trusted solution across diverse sectors:

Produzione e magazzinaggio: Handles heavy equipment and pallet jack traffic.

Lavorazione di alimenti e bevande: Provides seamless, cleanable, and chemical-resistant floors.

Automotive & Repair Shops: Resists oil, grease, and tire marks.

Farmaceutici e laboratori: Ensures a contaminant-free, easy-to-sanitize environment.

Cucine commerciali e birrerie: Withstands thermal shock, high moisture, and frequent cleaning.

Parcheggi e centri logistici: Durable and aesthetically pleasing for public and commercial use.

Processo di installazione professionale

A proper installation is key to performance. Our recommended process, supported by our technical team, ensures optimal results:

Surface Preparation (Prep): Critical first step. The concrete substrate is shot-blasted to a CSP 3-4 profile to ensure optimal adhesion. All cracks are filled, and moisture testing (per ASTM F2170) is conducted.

Priming: A dedicated primer (e.g., ResuShield Glaze) is applied to seal the substrate and enhance bond strength.

Basecoat Application: The 100% solids, self-leveling epoxy slurry is mixed with selected aggregates and applied using a notched squeegee to achieve the specified thickness.

Applicazione della finitura: A high-performance urethane topcoat (ResuShield AT) is rolled on, providing the final chemical and abrasion resistance and desired gloss level.

Curing & Protection: The floor is cured as per manufacturer guidelines before allowing light foot traffic and full service.

We provide comprehensive support from specification to installation, ensuring your project’s success.

Domande frequenti (FAQ)

Q: How long does the ResuShield™ Gard SL installation take?

A: Project timelines vary based on area size and conditions. Typically, after proper substrate prep, the coating application and curing can take 3-5 days for a standard area. We provide detailed schedules during project planning.

Q: What is the difference between epoxy and polyurethane topcoats?

A: While both are durable, the urethane topcoat in our system offers superior resistance to UV yellowing, abrasion, and thermal shock compared to standard epoxy top layers, making it tougher and longer-lasting.

Q: Can this system be installed in my basement or over existing tile?

A: It is primarily designed for industrial concrete slabs. For residential basement or over-tile applications, a specific site evaluation is required to recommend the correct prep and products.

D: Quale manutenzione è necessaria?

A: Maintenance is simple. Daily dust mopping and occasional damp mopping with a neutral pH cleaner are sufficient. Avoid harsh chemicals or abrasive pads.

Why Choose Our Solution?

We are more than just a manufacturer or supplier. As KAIDA PAINT, we bring deep expertise as both a certified coatings producer and a seasoned project partner. We understand that a floor is a critical business asset. Our team works directly with contractors, companies, and facility managers to deliver not just products, but solutions that reduce long-term cost, minimize downtime, and enhance operational efficiency. We stand behind our systems with technical support and a commitment to quality.

Ready to Transform Your Floor?

Stop dealing with constant repairs, cleaning struggles, and safety concerns. Invest in a floor that performs as hard as your business does.

Contact KAIDA PAINT today for a free consultation, quote, or to request technical data sheets and project pictures. Let our experts help you specify the right system for your needs and connect you with certified professional installers in your city or country.

KAIDA PAINT Brand Introduction

At KAIDA PAINT, we specialize in high-performance flooring solutions for the most demanding industrial and commercial applications. As both a leading manufacturer and a partner to certified contractors, we provide more than just premium products like the ResuShield™ Gard SL system. We deliver end-to-end project support—from technical specification and on-site prep guidance to installation oversight. Our commitment is to ensure your flooring investment delivers long-term value, durability, and performance. Have a challenging floor project? Contact our team of experts today for a tailored solution.