Descrizione

Panoramica del prodotto

The Polypro™ Advanced NMP Performance EV is a high-performance, multi-layer urethane flooring system engineered specifically for demanding industrial environments, particularly electric vehicle (EV) battery manufacturing and chemical processing facilities. This epoxy-based system with specialized urethane topcoats delivers industry-leading resistance to harsh chemicals like N-Methyl-2-pyrrolidone (NMP), combined with superior durability and safety features. It provides a seamless, easy-to-clean surface that protects concrete substrates from degradation, offering a robust, long-lasting flooring solution for critical industrial applications.

User Pain Points & Scenario Analysis

Choosing the wrong flooring for heavy-duty industrial settings leads to costly downtime, safety hazards, and frequent repairs. Common pain points include:

Attacco chimico: Floors in EV battery plants (formation, cell assembly, cathode areas) are exposed to aggressive solvents like NMP, which can rapidly degrade standard epoxy or polyurethane coatings.

Safety Risks: Slippery surfaces, especially when contaminated with carbon black or other processing materials, increase the risk of workplace accidents.

Mechanical Wear & Tear: Constant traffic from heavy equipment, carts, and foot traffic wears down flooring, causing dusting, cracking, and loss of integrity.

Moisture Issues: Moisture vapor emission from concrete slabs can blister and delaminate improperly sealed flooring systems.

Difficult Maintenance: Porous or textured floors that trap contaminants are difficult and expensive to clean, affecting facility hygiene and operations.

The Polypro™ Advanced NMP Performance EV system is designed to directly address these challenges, providing a coating that is as tough as your operations.

Product Solution & Key Features

Our urethane flooring system isn’t just a paint or a simple sealer; it’s an engineered solution. Here’s what makes it stand out:

1. Unmatched Chemical Resistance

14-Day NMP Resistance: Tested in accordance with ASTM D1308 under glass, offering exceptional protection in areas with high chemical attack.

Broad Spectrum Resistance: The topcoat and system provide robust resistance against a wide range of industrial chemicals, oils, and solvents, safeguarding your concrete substrate.

2. Enhanced Safety & Cleanability

Anti-Slip Texture: Features a fine-textured, satin finish that provides a high Dynamic Coefficient of Friction (DCOF of 0.72 per ANSI A326.3), significantly improving traction over standard surfaces, even in the presence of carbon black.

Seamless & Non-Porous: Creates a monolithic surface with no grout lines or seams to harbor bacteria, grease, or debris. Spills wipe up easily, supporting stringent cleanliness protocols.

3. Superior Durability & Performance

Exceptional Abrasion Resistance: With only 11.7 mg loss (ASTM D4060), the topcoat lasts twice as long as standard urethanes, reducing long-term cost.

High Adhesion: Achieves over 450 psi (ASTM D4541), ensuring the system bonds tenaciously to the concrete substrate, preventing delamination.

Rapid Installation & Cure: Can be applied to green concrete (7 days old vs. standard 28), featuring a fast cure time to minimize facility downtime.

4. Complete System Integrity

Integrated Moisture Vapor Barrier: The Resuprime™ MVB coat mitigates moisture-related failures, a critical consideration for slab-on-grade applications.

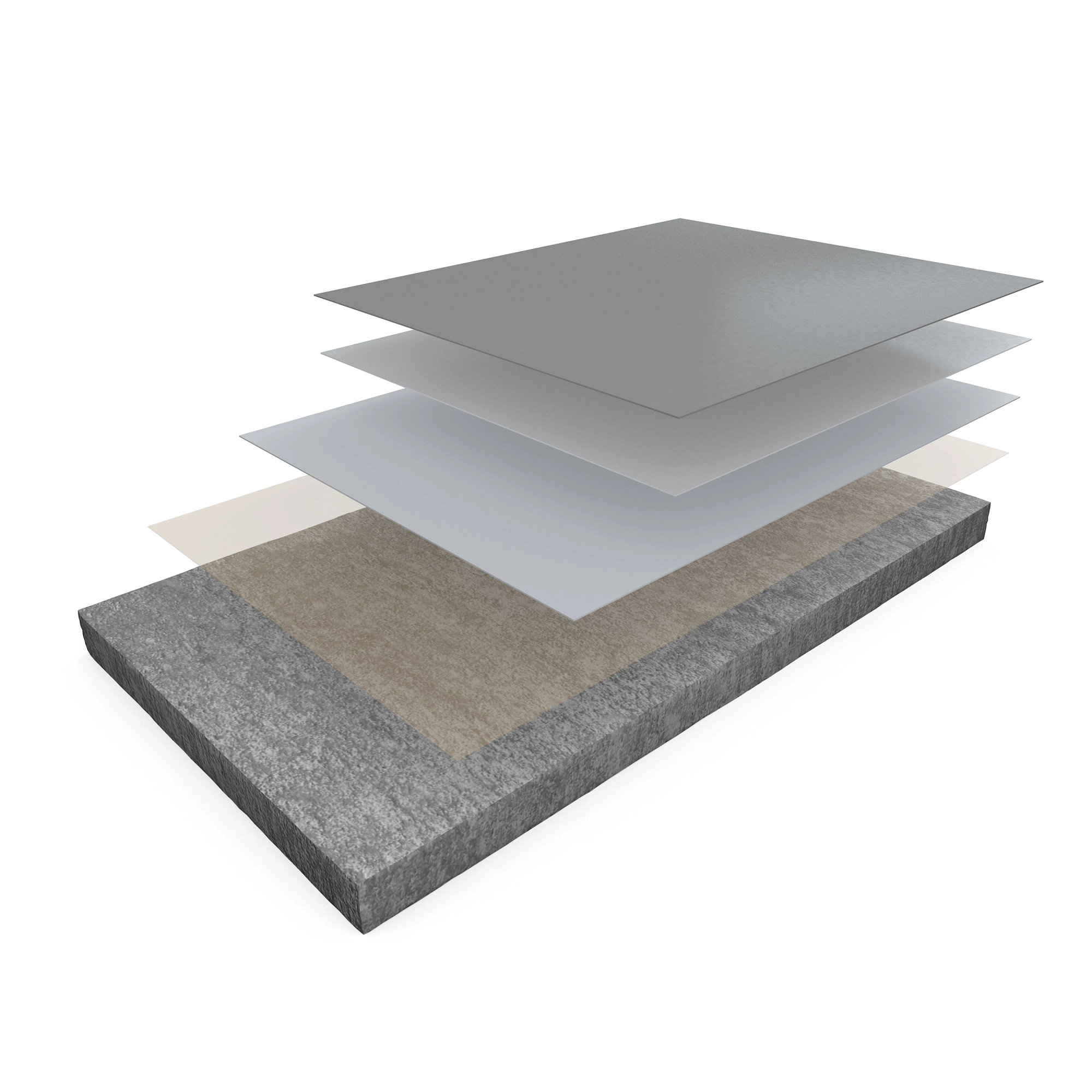

Multi-Layer Protection: The system comprises a moisture barrier, epoxy basecoat, NMP-protective layer, and the final slip-resistant urethane topcoat, each layer serving a specific protective function for total concrete protection.

Technical Parameters Data

| Proprietà | Metodo di prova | Result/Value |

|---|---|---|

| NMP Chemical Resistance | ASTM D1308 | No Effect (NE) for 14 days |

| Resistenza all'abrasione | ASTM D4060 (CS-17 Wheel, 1k cycles) | 11.7 mg loss |

| Adhesion to Concrete | ASTM D4541 | >450 psi (Concrete Failure) |

| Dynamic Coefficient of Friction (DCOF) | ANSI A326.3 | 0.72 |

| Durezza | ASTM D2240 (Shore D) | 80-85 @ 0 sec; 75-80 @ 15 sec |

| Infiammabilità | ASTM D635 | 182 mm/min |

| Spessore totale del sistema | Nominal | 43 mils |

Aree di applicazione

This urethane flooring system is ideal for environments demanding the highest performance:

EV Battery Manufacturing: Formation rooms, cell assembly, cathode production areas.

General Chemical Processing Plants

Pharmaceutical & Life Sciences: Cleanrooms, labs, production areas requiring chemical resistance and easy cleaning.

Cibo e bevande: Processing areas where chemical spills and stringent wash-downs occur.

Heavy Industrial & Warehousing: Areas subject to extreme abrasion and chemical exposure.

Professional Installation & Technical Support

Proper installation is critical to achieving the designed performance. The system requires specific surface preparation (typically CSP 3-5 profile via abrasive blasting) and precise application techniques.

Key Steps Include:

Preparazione della superficie: Abrasive blast concrete to remove contaminants and achieve proper profile.

Moisture Vapor Barrier: Apply Polyprime MVB at specified coverage.

Basecoat Application: Apply Polypro MPE epoxy basecoat.

NMP Protective Layer: Apply Polypro HPS 100.

Topcoat Application: Apply the final Polypro HTS 100 slip- and chemical-resistant urethane topcoat.

We strongly recommend working with our network of qualified, manufacturer-trained contractors and installers. KAIDA PAINT provides comprehensive technical support, from specification and system design to on-site application guidance, ensuring your flooring investment performs as promised.

Domande frequenti (FAQ)

Q1: How does this urethane flooring compare to a standard epoxy system?

A: While both are resinous floorings, this urethane topcoat offers significantly higher chemical resistance (especially to NMP), superior abrasion resistance (2x longer life), and better flexibility, reducing the risk of cracking under thermal or structural stress. It is the preferred finish for the most demanding chemical and traffic environments.

Q2: What is the minimum required concrete substrate cure time before application?

A: The system can be applied to green concrete as young as 7 days old, thanks to the moisture-tolerant primer, accelerating project timelines compared to the traditional 28-day wait.

Q3: How do I maintain a Polypro™ Advanced NMP Performance EV floor?

A: Daily maintenance is simple: remove spills promptly and clean with neutral pH detergents. Avoid harsh, unapproved chemicals. For heavy soiling, use non-aggressive mechanical scrubbers. Regular inspection and immediate spot repair of any damage will maximize system life.

Q4: What is the typical lead time for installation and when can the floor be used?

A: The installation schedule depends on area size and conditions. The floor can typically accept light traffic after 24 hours at 75°F (24°C), but full chemical and physical properties develop over 14 days.

Why Choose This System?

This isn’t just another industrial coating. It’s a specification-grade solution backed by rigorous testing and designed for a specific, severe operational challenge. By selecting the Polypro™ Advanced NMP Performance EV system, you are investing in:

Reduced Lifetime Cost: Longer service life means fewer replacements.

Enhanced Operational Safety: A proven anti-slip surface protects your workforce.

Uninterrupted Operations: Durable and chemical-resistant, minimizing emergency repairs and downtime.

A Trusted Partnership: Support from raw material to installed finish.

Contact KAIDA PAINT for Your Industrial Flooring Solution

At KAIDA PAINT, we are more than just a supplier of high-performance coatings; we are your dedicated partner in industrial asset protection. We specialize in formulating and delivering advanced resin-based flooring systems, like the Polypro™ Advanced NMP Performance EV, that solve real-world problems for companies across demanding sectors.

Our products are developed with deep industrial expertise, and our process includes comprehensive support for contractors and facility owners. From initial specification and cost estimation to providing detailed pictures and specifications for your project docs, we ensure a seamless process. We collaborate closely with professional installers to guarantee every application meets the highest standards, ensuring the basecoat, mortar, and topfloor finish perform as an integrated, protective system.

Ready to specify a flooring system that meets the severe demands of your facility? Contact our expert team today for a consultation, technical data sheets, and to connect with a qualified installer in your region.