Descrizione

FortiFlex B è un sistema di pavimentazione in quarzo a tinta unita ad alte prestazioni, progettato per ambienti in cui la durata, l'igiene e i tempi di inattività sono fondamentali. Combinando una formulazione epossidica a base di solidi 100% con quarzo a gran fuoco, questo sistema offre una superficie strutturata e antiscivolo che resiste al traffico pedonale intenso, alle fuoriuscite di sostanze chimiche e all'esposizione ai raggi UV. Con uno spessore nominale di 1/8″ e un tempo di polimerizzazione di appena 2 ore per mano, FortiFlex B è la soluzione ideale per le strutture che operano 24 ore su 24, 7 giorni su 7.

Caratteristiche e vantaggi principali

- Tecnologia di polimerizzazione rapida

Raggiunge l'idoneità al traffico pedonale in 2,5-5 ore (a seconda della temperatura).

Ripristino del servizio completo entro 24 ore, per ridurre al minimo le interruzioni operative.

- Eccezionale durata

Resistenza alla compressione: 12.500 psi (ASTM C-379).

Resistenza alla trazione: 4.000 psi (ASTM D-638).

Resiste all'abrasione, agli urti e ai carichi pesanti, ideale per ambienti industriali e commerciali.

- Resistenza superiore agli agenti chimici e ai raggi UV

Resiste ai comuni prodotti chimici, ai disinfettanti e agli oli.

La finitura stabile ai raggi UV impedisce l'ingiallimento e lo sbiadimento, ideale per showroom e laboratori.

- Antiscivolo e sicuro

La finitura al quarzo testurizzata garantisce la trazione anche quando è bagnata.

Soddisfa gli standard ANSI per il coefficiente di attrito statico (>0,6) e dinamico (>0,42).

- Senza cuciture e igienico

La superficie non porosa inibisce la crescita microbica, facile da pulire e da mantenere.

Ideale per camere bianche, strutture farmaceutiche e aree di lavorazione degli alimenti.

- Estetica personalizzabile

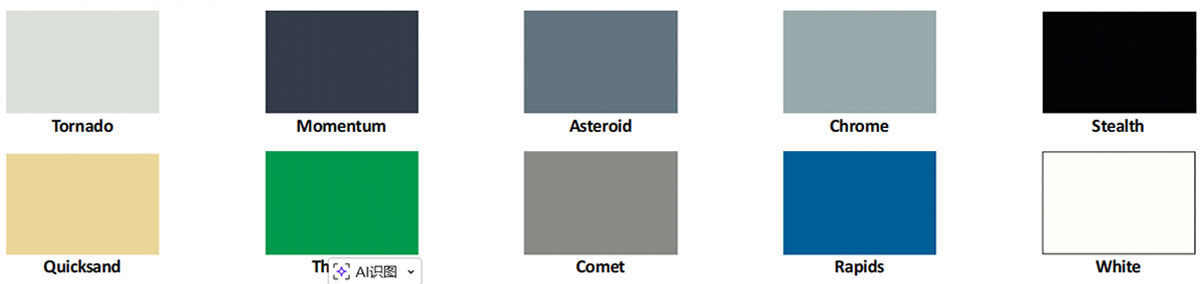

Disponibile in colori standard e personalizzati (ad esempio, Tornado, Bianco, Stealth).

Utilizzate il nostro strumento di visualizzazione dei pavimenti per vedere in anteprima i colori nel vostro spazio.

Specifiche tecniche

| Proprietà | Valore |

|---|---|

| Spessore totale del sistema | 1/8″ |

| Peso Solidi | 96% |

| Contenuto di VOC | 33 g/L |

| Temperatura di servizio | Fino a 200°F |

| Resistenza all'abrasione Taber (ASTM D-4060) | 25 mg |

| Durata del vaso a 70°F | 10-15 min |

| Resistenza chimica completa | 7 giorni |

| Indice di propagazione della fiamma (ASTM E-84) | Classe B |

Componenti del sistema

Primer - Assicura un'adesione superiore ai substrati di calcestruzzo.

Rivestimento di base/diffusione - Resina pigmentata con prima trasmissione di quarzo.

Seconda trasmissione - Migliora la consistenza e l'uniformità del colore.

Stuccatura/guarnizione - Fornisce una finitura senza giunture e resistente agli agenti chimici.

Applicazioni ideali

Camere bianche e laboratori

Strutture farmaceutiche e sanitarie

Scuole e università

Supermercati e caffetterie

Showroom e spazi commerciali

Servizi igienici e spogliatoi

Perché scegliere FortiFlex B?

A differenza dei tradizionali sistemi epossidici a scaglie o dei pavimenti in trucioli di vinile, FortiFlex B utilizza una trasmissione di quarzo in tinta unita per una durata ineguagliabile e una finitura uniforme e a bassa manutenzione. Il suo rapido tempo di polimerizzazione supera i tradizionali rivestimenti per pavimenti poliaspartici, rendendolo la scelta intelligente per i progetti sensibili ai tempi.

Domande frequenti

D: Come si colloca il FortiFlex B rispetto alla pavimentazione epossidica a scaglie?

R: Sebbene entrambi i sistemi utilizzino le trasmissioni, il FortiFlex B incorpora il quarzo selciforme per una maggiore resistenza all'usura e un colore solido e uniforme, a differenza delle scaglie decorative.

D: Posso utilizzare FortiFlex B in aree umide?

R: Sì! La finitura strutturata e il rivestimento resistente agli agenti chimici lo rendono adatto a bagni, spogliatoi e aree di ristorazione.

D: Questo sistema è adatto al fai-da-te?

R: A causa della rapida durata dei vasi e dei requisiti di applicazione professionale, raccomandiamo l'installazione da parte di appaltatori certificati.

Fiducia da parte dei leader del settore

Sostenuto da KAIDA PAINT' L'esperienza globale nelle pavimentazioni ad alte prestazioni, FortiFlex B è supportata da:

Servizi di assistenza tecnica e specifiche.

Strumenti di visualizzazione del design e di abbinamento dei colori personalizzati.

Team commerciali regionali per un supporto localizzato.

Invito all'azione

Siete pronti a trasformare il vostro spazio?

📞 Contattate oggi stesso un esperto di pavimenti KAIDA PAINT per un preventivo o un campione.