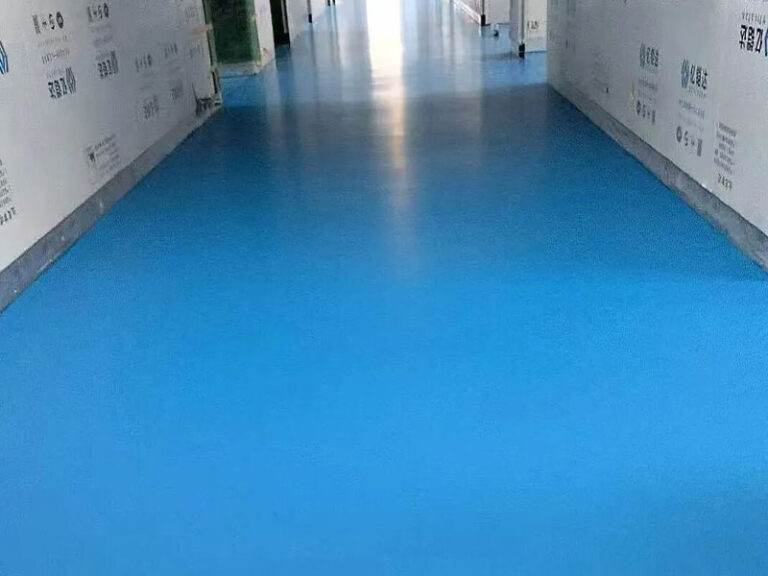

Nell'industria farmaceutica, altamente regolamentata, ogni superficie deve soddisfare rigorosi standard di pulizia e sicurezza. Quando si pianifica il piano di produzione farmaceutica, la scelta della pavimentazione farmaceutica è probabilmente una delle decisioni più critiche. Essa costituisce la base dell'ambiente controllato. Questa guida spiega perché la pavimentazione in malta uretanica a base d'acqua KAIDA PAINT JINYU® , combinata con il nostro sistema di base cove, rappresenta il punto di riferimento per le moderne soluzioni di pavimentazione farmaceutica, superando le opzioni tradizionali come la pavimentazione epossidica farmaceutica standard.

Qual è la pavimentazione migliore per le strutture farmaceutiche? Malta uretanica vs. epossidica

Mentre i pavimenti epossidici per l'industria farmaceutica sono comuni, le pavimentazioni avanzate Sistemi di pavimenti in malta uretanica offrono prestazioni superiori per gli ambienti GMP più esigenti. Per le pavimentazioni delle camere bianche farmaceutiche, delle fabbriche farmaceutiche e dei laboratori farmaceutici, i fattori chiave di differenziazione sono la resistenza agli shock termici, la durata e l'igiene. KAIDA PAINT® è specializzata in rivestimenti per pavimenti farmaceutici ad alte prestazioni, progettati per eccellere in queste aree.

5 vantaggi dei nostri sistemi di pavimentazione farmaceutica in malta uretanica

- Resistenza chimica superiore per impianti farmaceutici

I processi di produzione farmaceutica coinvolgono sostanze chimiche aggressive. Il nostro rivestimento per pavimenti in poliuretano offre un'eccezionale resistenza agli acidi, agli alcali e ai solventi, proteggendo il substrato in calcestruzzo molto meglio di molti altri pavimenti epossidici per l'industria farmaceutica. Questa durata riduce al minimo i tempi di inattività e le riparazioni, rendendo la pavimentazione farmaceutica una soluzione economicamente vantaggiosa. - Eccezionale stabilità termica per le aree sterili e di conservazione del freddo

Dalle celle frigorifere alle aree autoclave, il nostro pavimento in malta uretanica resiste a cicli termici estremi senza incrinarsi. Questa stabilità è fondamentale per l'integrità della pavimentazione delle camere bianche farmaceutiche, in quanto impedisce la formazione di punti di rifugio per i microbi che possono affliggere i pavimenti meno flessibili. - Igiene e pulizia migliorate per la conformità alle GMP

La superficie non porosa e senza giunture dei nostri sistemi di pavimentazione farmaceutica impedisce l'assorbimento dei liquidi e inibisce la crescita microbica. In combinazione con la nostra base integrale, crea una superficie monolitica da parete a parete, eliminando gli angoli e garantendo la conformità agli standard GMP e FDA per la pavimentazione degli impianti farmaceutici. - Durata in presenza di carichi pesanti e traffico

La resistenza meccanica dei nostri pavimenti resiste alle attrezzature pesanti e al traffico frequente. Questa robustezza è essenziale per le esigenze operative degli impianti farmaceutici che devono sopportare i pavimenti epossidici, riducendo i costi di manutenzione a lungo termine. - Installazione priva di VOC e sicura per l'ambiente

La nostra formula a base d'acqua garantisce emissioni di COV prossime allo zero durante l'installazione e per tutta la durata del prodotto. Si tratta di una caratteristica di sicurezza fondamentale per qualsiasi progetto di verniciatura dei pavimenti di un impianto farmaceutico, che protegge sia la qualità del prodotto che la sicurezza dei lavoratori.

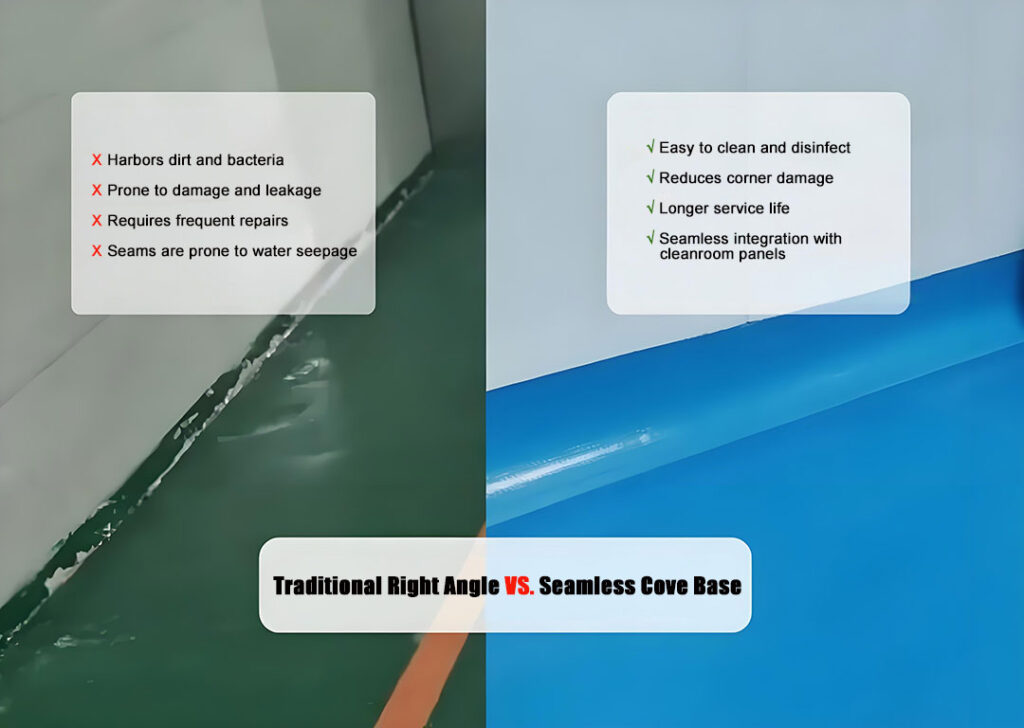

Il dettaglio critico: Base a conca senza cuciture di KAIDA PAINT

Un vero sistema di pavimentazione per camere bianche farmaceutiche è incompleto senza affrontare la giunzione parete-pavimento. I tradizionali angoli di 90 gradi sono pericolosi per l'igiene. Il nostro design senza soluzione di continuità della base è una pietra miliare dei nostri sistemi di pavimentazione farmaceutica, che crea una transizione curva e facile da pulire che è parte integrante del pavimento stesso. In questo modo si elimina una fonte primaria di contaminazione ed è una best practice per qualsiasi appaltatore di pavimenti farmaceutici.

Perché scegliere KAIDA PAINT® come partner per la pavimentazione farmaceutica?

La scelta del giusto appaltatore di pavimentazioni farmaceutiche è importante quanto la scelta del materiale. KAIDA PAINT® è specializzata in servizi di pavimentazione per le industrie farmaceutiche. Non offriamo solo prodotti, ma soluzioni complete per la pavimentazione farmaceutica, supportate da competenze tecniche. I nostri posatori di pavimenti farmaceutici sono addestrati a soddisfare i protocolli unici delle installazioni di strutture farmaceutiche, assicurando un risultato perfetto, conforme e performante per il vostro progetto di pavimentazione dell'industria farmaceutica.

Per i pavimenti farmaceutici che offrono durata, pulizia e conformità senza pari, KAIDA PAINT JINYU® Malta uretanica all'acqua è la scelta definitiva. Rappresenta l'evoluzione della pavimentazione epossidica farmaceutica standard, offrendo una soluzione avanzata per la pavimentazione della produzione farmaceutica.