Descrizione

Panoramica del prodotto

ResuShield™ Mechanical Room DB is a heavy-duty, multi-coat epoxy flooring system engineered for demanding industrial and commercial mechanical room applications. This high-performance system combines a flexible waterproofing membrane with multiple broadcast layers of silica sand, resulting in an exceptionally durable, chemical-resistant, and slip-resistant floor finish. It delivers superior crack-bridging capabilities, high mechanical wear resistance, and long-term protection against water, chemicals, and physical impact. The ResuShield™ Mechanical Room DB epoxy flooring system is the definitive solution for protecting critical infrastructure in facilities requiring a robust, low-maintenance, and safe flooring surface.

User Pain Points & Application Scenarios

Industrial and commercial facility managers face significant challenges with standard flooring. Common issues include:

Cracks & Damage: Heavy equipment, thermal cycling, and substrate movement cause cracks and surface degradation, leading to leaks and failures.

Corrosione chimica: Spills from oils, lubricants, coolants, and cleaning agents deteriorate concrete, creating safety hazards and unsanitary conditions.

Abrasion & Wear: Constant foot and cart traffic, dropped tools, and rolling loads quickly wear down surfaces, generating dust and requiring frequent repairs.

Moisture & Waterproofing Failures: In mechanical rooms, plumbing leaks and condensation can compromise subfloors and equipment, demanding a truly waterproof solution.

Safety & Slip Hazards: Wet or oily conditions on slick surfaces pose major slip-and-fall risks, especially in utility and maintenance areas.

The ResuShield™ Mechanical Room DB system directly addresses these pain points in critical environments like:

HVAC & Utility Mechanical Rooms: Where waterproofing and durability are non-negotiable.

Industrial Manufacturing Plants: Exposed to chemicals, heavy loads, and thermal stress.

Pharmaceutical & Food Processing Backup Areas: Requiring seamless, cleanable surfaces that resist microbial growth.

Data Center Support Floors: Needing reliable protection from potential water leaks near critical infrastructure.

Parking Garage Mechanical Levels: Subject to vehicle traffic, salts, and water exposure.

Product Solution & Key Features

The ResuShield™ Mechanical Room DB epoxy flooring system is a comprehensive solution built for longevity and performance.

Core System Advantages:

Unmatched Durability: A six-coat system with a double broadcast of 20-40 mesh silica sand creates an aggressive texture and incredible thickness for extreme wear resistance.

Superior Waterproofing: The flexible membrane core provides exceptional crack bridging and a continuous waterproof barrier, protecting the concrete substrate.

Resistenza chimica: Resistant to a wide range of industrial chemicals, oils, and solvents, making clean-up easy and preventing permanent stains.

Sicurezza migliorata: The textured, slip-resistant finish (even when wet) meets high safety standards, reducing accident risks in industrial settings.

Senza cuciture e igienico: The fluid-applied system creates a monolithic, non-porous surface that prevents dirt and moisture accumulation, simplifying cleaning.

Long-Lasting Aesthetics: The UV-stable, satin urethane topcoat retains its color and finish, resisting yellowing and degradation from exposure.

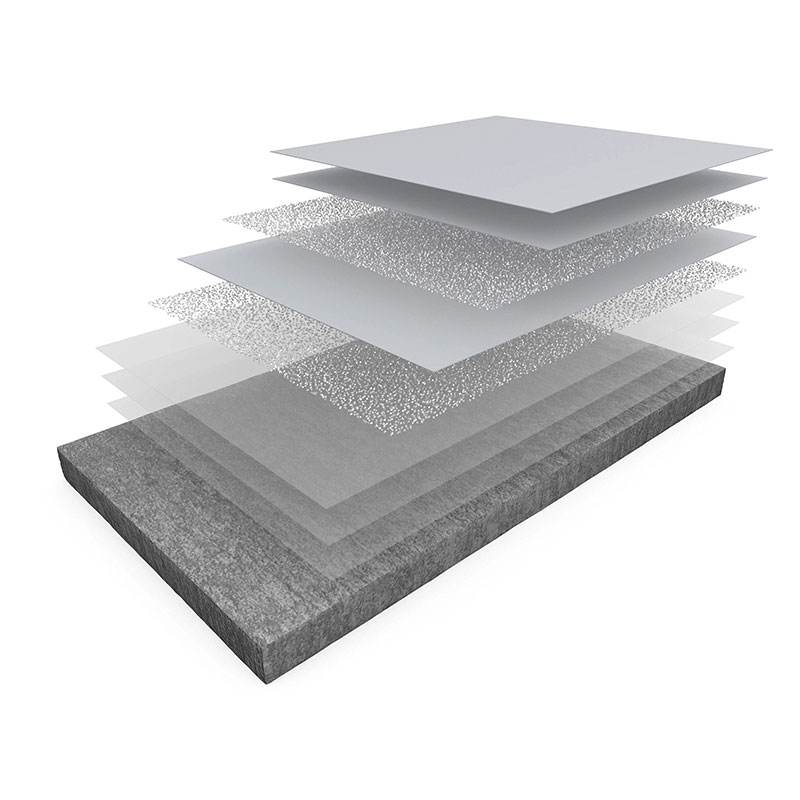

Detailed System Composition:

Primer (Resuflor™ MPE): A flexible epoxy primer applied at 3-5 mils for superior substrate adhesion and crack isolation.

Membrane Build Coats (Resuflor™ 3555): Two 20-mil coats of a high-build, flexible epoxy membrane form the waterproofing core.

Reinforcement Broadcasts: Two separate layers of 20-40 mesh silica sand are broadcast into the wet epoxy, creating a deeply textured, reinforced composite layer for ultimate strength and slip resistance.

Grout Coat (Resuflor™ MPE): A 15-mil coat seals the broadcast aggregate, providing a solid, level base for the topcoat.

Topcoat (Resutile™ HTS 100): A durable, light-stable urethane topcoat in a satin finish provides final chemical and abrasion resistance, with excellent color retention.

Technical Specifications & Data

The performance of the ResuShield™ Mechanical Room DB system is verified by standardized testing.

| Proprietà | Metodo di prova | Risultato | Nota |

|---|---|---|---|

| Hardness (Shore D) | ASTM D 2240 | 40 @ 0 sec. | 35 @ 15 sec. |

| Resistenza alla trazione | ASTM D 2370 | 18,530 psi | 7 mils, 3-day cure |

| Elongation | ASTM D 2370 | 125% | 7 mils, 3-day cure |

| Adesione al calcestruzzo | ACI 503R | >300 psi | Cohesive concrete failure |

| Resistenza all'abrasione | ASTM D 4060 | 5.1 mg loss | CS-17 Wheel, 1000 cycles |

| Infiammabilità | ASTM D635 | 182 mm/min | |

| Contenuto di VOC | — | <50-100 g/L | Meets stringent regulations |

| Temperatura di servizio | — | Continuous exposure up to 140°F (60°C) | |

| Resistenza allo scivolamento | — | High (Wet & Dry) | Aggressive texture from double sand broadcast |

Aree di applicazione

This versatile epoxy flooring system is specified by companies and contractors for numerous demanding sectors:

Industrial & Manufacturing: Factory floors, production areas, warehouses, and assembly lines.

Commercial & Institutional: Mechanical rooms, elevator pits, loading docks, and service corridors in hospitals, schools, and office buildings.

Cibo e bevande: Processing support areas, wash-down zones, and utility spaces requiring USDA-compliant, cleanable surfaces.

Automotive: Service bays, repair shops, and parts warehouses exposed to fluids and heavy traffic.

Pharmaceutical & Chemical: Utility plants, storage rooms, and labs needing chemical resistance.

Parking & Transportation: Enclosed parking areas, garage mechanical floors, and maintenance facilities.

Processo di installazione professionale

Proper installation is critical for system performance. KAIDA PAINT partners with certified contractors to ensure flawless execution.

Surface Preparation (Prep): Concrete is abrasive-blasted to a CSP 3-5 profile to remove contaminants and laitance. Cracks are routed and filled.

Primer Application: Resuflor™ MPE primer is mixed and applied to seal and prepare the substrate.

Membrane & Broadcast Layers: The ResuShield™ 2444 membrane coats are applied, each immediately broadcast with silica sand for reinforcement.

Grout & Topcoat: The grout coat seals the aggregate, followed by the final Resutile™ HTS 100 urethane topcoat for protection and a uniform finish.

Polimerizzazione e messa in servizio: The floor cures for 24 hours before light traffic, achieving full properties within 14 days.

Our Technical Support: We provide comprehensive support from specification to project completion, including site audits, technical data sheets, and on-site guidance for contractors.

Domande frequenti (FAQ)

Proof & Trust Building

Certified Performance: Data based on independent laboratory testing per ASTM standards.

Trusted by Industry Leaders: Specified by major companies for critical infrastructure projects globally.

Expert-Backed: Formulated and supported by Sherwin-Williams High Performance Flooring’s technical service team.

Durable Results: See project pictures showcasing long-lasting performance in harsh conditions.

KAIDA PAINT Brand Introduction

KAIDA PAINT is a leading innovator and supplier of high-performance industrial and commercial coating solutions. With a relentless focus on quality, durability, and technical support, we partner with facility managers, specifiers, and professional contractors to solve complex flooring challenges. Our ResuShield™ line, including the flagship Mechanical Room DB system, embodies our commitment to delivering products that outperform under extreme conditions. Backed by rigorous R&D and a global network of experts, we don’t just sell paint; we deliver long-term asset protection and peace of mind. Ready to specify the best floor for your project? Consult with a KAIDA PAINT expert today.

Partner with KAIDA PAINT

Choosing the right flooring system is a significant decision for your business. At KAIDA PAINT, we are more than a manufacturer; we are your technical partner in specifying and delivering high-performance flooring solutions. Our team provides expert guidance, from initial design ideas and product selection to supporting your chosen professional installer.

We understand that cost, performance, and longevity are critical. The ResuShield™ Mechanical Room DB epoxy flooring system represents the pinnacle of industrial floor protection. Contact our technical specialists today for a consultation, a detailed quote, or to find a certified contractor near you. Let us help you prepare a floor that will withstand the test of time.