Saat mendesain atau merenovasi pabrik pengolahan makanan, pilihan lantai industri makanan adalah keputusan penting yang berdampak pada segala hal mulai dari keamanan makanan hingga efisiensi operasional. Hal ini terutama berlaku pada lantai pengolahan kedelai, di mana lingkungannya berada dalam kondisi yang unik dan ekstrem.

Bagi produsen yang mencari lantai terbaik untuk aplikasi pabrik pengolahan makanan, memahami keterbatasan opsi tradisional seperti lantai epoksi untuk industri makanan dan keuntungan dari solusi modern seperti lantai mortar uretan tanpa sambungan sangat penting. Analisis ini mengeksplorasi studi kasus dunia nyata dari produsen kedelai terkemuka di Cina Timur yang meningkatkan lantai produksi makanannya untuk memecahkan masalah yang terus berlanjut.

Tantangan Lantai Pengolahan Kedelai: Mengapa Opsi Standar Gagal

Lantai pengolahan kedelai harus tahan terhadap kombinasi faktor yang brutal:

- Serangan Asam: Air bubur kuning dari perendaman dan pengepresan bersifat sangat asam.

- Thermal Shock: Lantai transisi antara area pencucian panas dan area penyimpanan dingin.

- Beban berat: Lalu lintas forklift yang konstan menuntut daya tahan yang ekstrem.

- Keharusan Kebersihan: Lantai yang aman untuk makanan harus mulus dan mudah dibersihkan untuk mencegah pertumbuhan mikroba.

Bahan tradisional seperti lantai epoksi untuk pengolahan makanan dan marmer adalah pilihan yang umum tetapi bermasalah untuk lantai di area persiapan makanan.

Kegagalan Utama dari Lantai Pemrosesan Makanan yang Tidak Memadai:

- Korosi Kimia: Lapisan epoksi dapat terdegradasi, memungkinkan asam menembus substrat beton. Hal ini membahayakan integritas lantai industri makanan dan menciptakan risiko kebersihan.

- Bahaya Terpeleset: Permukaan yang licin saat basah membuat lantai untuk pengolahan makanan menjadi masalah keamanan utama.

- Umur Pendek: Sifat epoksi yang rapuh menyebabkan keretakan di bawah siklus termal, menjadikannya solusi jangka pendek yang mahal untuk lantai makanan dan minuman.

Solusi Optimal: Lantai Mortar Uretan Berbasis Air

Untuk pabrik kedelai ini, solusi yang tepat adalah lantai mortar uretan yang ditularkan melalui air. Jenis pelapis lantai poliuretan ini secara luas dianggap oleh para ahli sebagai lantai terbaik untuk lingkungan industri makanan karena sifat kompositnya: menggabungkan kekuatan mineral anorganik dengan fleksibilitas resin poliuretan organik.

Keuntungan Mortar Uretan untuk Lantai Pengolahan Kedelai:

- Ketahanan Kimia yang Unggul: Ini membentuk penghalang kedap air yang tidak berpori dan kedap air yang menahan air lumpur kuning dan asam, melindungi dasar beton. Ini adalah persyaratan mendasar untuk lantai yang aman bagi makanan.

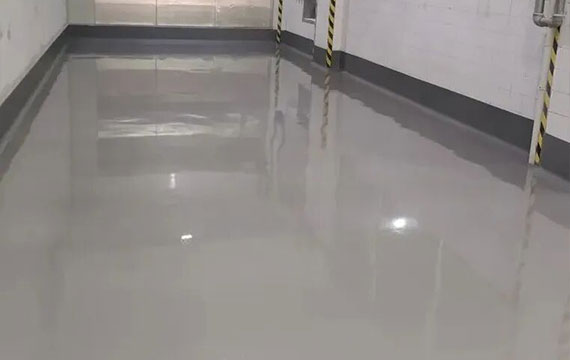

- Mulus & Higienis: Permukaan monolitik menghilangkan sambungan dan lapisan, yang merupakan area utama kontaminasi di lantai pabrik makanan. Ini memungkinkan pembersihan yang mudah dan menyeluruh.

- Daya Tahan Luar Biasa: Fleksibilitasnya menyerap benturan dari alat berat tanpa retak, mengungguli material kaku seperti lantai epoksi untuk industri makanan.

- Stabilitas Termal: Tetap stabil di bawah perubahan suhu yang ekstrem, membuatnya ideal untuk seluruh area lantai produksi makanan, dari freezer hingga ruang memasak.

- Keamanan yang Ditingkatkan: Memberikan ketahanan slip yang unggul bahkan dalam kondisi basah dan berminyak, fitur penting untuk keselamatan karyawan di lantai layanan makanan.

Studi Kasus: Mengubah Operasi Pabrik Kedelai

Penerapan sistem mortar uretan KAIDA JINYU PAINT® memberikan hasil yang langsung terlihat:

- Kebersihan: Menghilangkan bau dan pertumbuhan bakteri yang disebabkan oleh penetrasi cairan.

- Keamanan: Penurunan yang signifikan dalam insiden terpeleset dan jatuh di area basah.

- Total Biaya Kepemilikan: Pengurangan drastis dalam pemeliharaan dan waktu henti, membuktikan bahwa ini adalah lantai terbaik yang paling hemat biaya untuk pabrik pengolahan makanan dalam jangka panjang.

Kesimpulan: Menetapkan Standar untuk Lantai Pengolahan Makanan Modern

Transisi ke lantai mortar uretan berkinerja tinggi lebih dari sekadar peningkatan; ini merupakan investasi strategis dalam keamanan pangan, efisiensi operasional, dan keberlanjutan. Bagi perusahaan yang mengevaluasi lantai pengolahan makanan, kasus ini menunjukkan bahwa kinerja superior sistem berbasis poliuretan menawarkan laba atas investasi yang jelas.

Tentang KAIDA JINYU PAINT®

Kami mengkhususkan diri dalam solusi pelapis lantai poliuretan berkinerja tinggi dan berkualitas tinggi untuk industri makanan dan minuman global. Keahlian kami dalam lantai pengolahan kedelai membantu produsen membangun fasilitas yang lebih aman, lebih efisien, dan sesuai standar.

Apakah fasilitas Anda menghadapi tantangan serupa? Hubungi KAIDA JINYU PAINT® untuk penilaian profesional guna menemukan lantai terbaik untuk kebutuhan industri makanan.