Description

Présentation du produit

KAIDA PAINT JINYU® MF floor system is a seamless, solventfree, three-component polyurethane (PU, urethane) screed floor system. Created through the 3-dimensional crosslinking of polyurethane and concrete, it yields a robust structure used widely across food, beverage, and harsh industrial environments. This seamless, solvent-free industrial flooring system boasts exceptional high impact and wear resistance, alongside outstanding resilience to chemical corrosion, heat, and humidity. It maintains a clean, hygienic, and seamless surface, making it ideal for food and beverage plants and other harsh environments.

Applications for JINYU® MF PU Screed

JINYU® MF is the ideal flooring for high traffic areas and environments with moderate thermal shock. Key application scenarios include:

- Food & Beverage Plants: Raw material handling, dry storage, dry packing, and wet processing areas (without excessive oil).

- Logistical Facilities: Loading docks and unloading platforms.

- Cold Storage: Cold rooms and freezer facilities.

- Pharmaceutical Manufacturing: GMP-compliant production areas.

- Please consult the KAIDA solution team for other specific usage scenarios and custom flooring solutions.

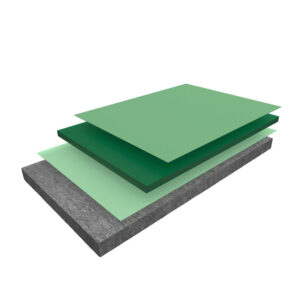

Couleur

There are seven standard colors available (approximate):

yellow, bege, gules, blue, green, light gray, dark gray

Des couleurs personnalisées peuvent être commandées sur la base de la QMOS.

Key Technical Data & Performance Parameters

Les données suivantes sont mesurées dans des conditions standard de laboratoire et peuvent présenter de légères différences par rapport aux données réelles sur place.

| Objet | Paramètres |

|---|---|

| Apparence | Après agitation, le mélange est uniforme et sans grumeaux. |

| Résistance à la traction (standard) | 5.5 N/mm² |

| Tensile Adhesion Strength (Soak in water) | 4.5 N/mm² |

| Shore Hardness D | 78.2 |

| Résistance à l'impact (bille d'acier de 1000g) | Pas de fissures ni de décollement |

| Résistance à l'abrasion (750g/500r) | 0.018g |

| Compressive Resistance | 71 MPa |

| Flexural Resistance (24h) | 13.3 MPa |

| Flexural Resistance (7d) | 15.7 MPa |

| Résistance aux acides (10% H₂SO₄, 48h) | Pas de bulles, pas de décollement, pas de décoloration. |

| Résistance à la base (30% NaOH, 48h) | Pas de bulles, pas de décollement, pas de décoloration. |

| Résistance au sel (3% NaCl, 7D) | Pas de bulles, pas de décollement, pas de décoloration. |

| Mildew Resistance | 0 (no fungal growth, best grade) |

Standard

JINYU PAINT® MF complies with the relevant requirements of GB/T22374 “Floor Coating Materials” standard.

Emballage

JINYU PAINT® MF is a pre-packaged three-component system, with a single set weighing 18.38kg:

Component A: 2.68 kg/bucket;

Component B: 2.5 kg/bucket;

Component C: 13.2 kg/package.

Model Specification

| Objet | Description |

|---|---|

| Système | JINYU PAINT MF |

| Finish | Matte finish |

| Épaisseur | 4-6 mm |

| Fabricant | KAIDA |

Preparatory work and application in accordance with manufacturer’s instructions.

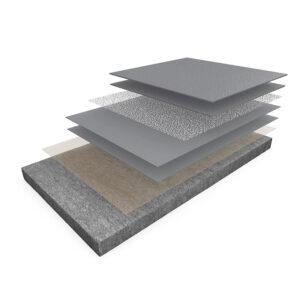

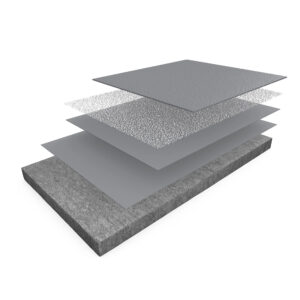

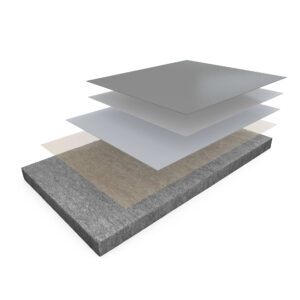

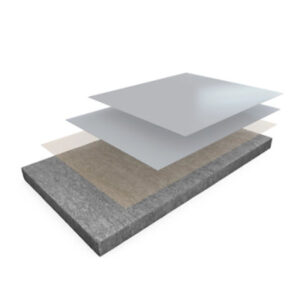

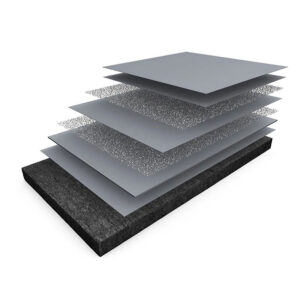

Recommended System Design for 4-6mm Thickness

Prepared Substrate (C25 concrete, tensile strength >1.5MPa, properly grooved)

Scratch Coat: JINYU PAINT MF1 Base (@ 1.8-2.0 kg/m²) – Trowel applied

Surface Coat: JINYU PAINT MF1 Topcoat (@ 6.0-6.5 kg/m²) – PU Screed Material

Products Included in this System

| Layer Type | Product Name | Application / Material Type |

|---|---|---|

| Couche de fond | Forincrete MF1 | Trowel Apply |

| Couche de finition | Forincrete MF1 | Forincrete MF1 PU Screed Material |

Method Statement

Optimal Application Conditions & Temperature

The ideal application temperature for JINYU PAINT® MF is between 15-25℃. It is not recommended to apply MF when the temperature is below 5℃, as it will seriously affect its leveling ability and result in surface defects. When the temperature is below 10℃, it can also significantly affect the curing speed of the product. If it is necessary to apply MF under temperature conditions exceeding 30℃, sufficient preparation work is required.

Concrete Substrate Preparation Guide

The ideal foundation condition for JINYU PAINT® MF requires a concrete base strength of over 30MPa. However, C25 concrete flooring with high-standard finishing can still meet the construction requirements.

Broyage : JINYU PAINT® MF requires grinding for base treatment with a coarser diamond blade. For very hard surfaces like wear-resistant floors, it is still recommended to use a shot blasting machine for sandblasting treatment.

Grooving: Multiple grooving needs to be cut close to the wall edge, with a depth of 6-9mm, a width of 5-8mm. The central area needs to be cut in both horizontal and vertical directions, with a spacing of about 2 meters.

For very hard or dense surfaces, shot blasting is the recommended preparation method to ensure optimal adhesion.

Mixing Instructions for 3-Component System

Before mixing, shake Part A well and then pour Part A and Part B into the bucket at the same time. Use a low-speed mixer to mix for about 5 seconds. It is recommended to use an electric mixer with adjustable speed and high torque at low speed. Then slowly pour in Part C bagged aggregate and mix at high speed for 1.5-2 minutes until completely uniform. Solvent or other diluting agents should not be added during mixing, and adding water is strictly prohibited.

Note : Le composant C est un composant nécessaire et doit être ajouté pendant l'agitation.

Rapport de mélange

Mixing all the raw materials from the complete set of factory packages

Application

Before scraping the primer, JINYU PAINT® MF requires pouring the material into the groove and scraping it flat.

Scratch Layer: Use a flat trowel or a 1mm serrated trowel to apply the coating according to the predetermined amount. During application, make sure to scrape it close to the ground and ensure the continuity of the coating to avoid any missed spots.

For concrete surfaces with low strength and flatness, it is recommended to apply two layers of scratch coat to achieve better sealing and flatness, which can improve the surface coating appearance.

Surface Layer: use a serrated rake or a 5mm serrated trowel for one-time spreading, with sufficient manpower to avoid joints. If the area is large, suitable isolation with decorative paper can be used in advance at the joint.

During the construction of surface coating, avoid direct sunlight and high temperatures, as they can affect the defoaming performance of the coating material and cause many air bubbles.

Expansion Joint: The existing expansion joints on the concrete floor should be marked before construction, and then cut again after the coating is completed, and filled with suitable elastic polyurethane joint sealant.

Nettoyage

Nettoyer les outils immédiatement après l'application à l'aide de solvants. Absorber tout produit répandu avec du sable sec ou d'autres matériaux absorbants et essuyer avec un chiffon.

Theoretical Consumption (4mm)

| Layer | Application Rate | Application Tool |

|---|---|---|

| Scratch Layer | 1.8-2.0 kg/m² | 1mm serrated trowel |

| Surface Layer | 6.0-6.5 kg/m² | 5mm serrated trowel |

Tout ajout ou réduction déraisonnable dans l'application du matériau peut affecter la qualité de l'interface, la performance d'étanchéité, la performance de collage, l'épaisseur du revêtement, etc. Par conséquent, la consommation du produit doit être conforme à l'utilisation recommandée et ajustée en fonction de la situation réelle sur le site afin d'obtenir des performances idéales.

Application Time & Curing Time

| Paramètres | Condition | 20°C | 30°C |

|---|---|---|---|

| La vie en pot | 25 min | 15 min | |

| Minimal Interval for next coating | >8 hr | 6 hr | |

| Temps de séchage | Surface sèche | Trafic léger | Cure complète |

| +20°C/2mm | ~14-16h | ~24-36h | ~7d |