Description

Aperçu du produit

Polypro™ XT Topfloor is a family of high-performance, seamless flooring systems engineered for demanding industrial and commercial environments. Built on a proprietary urethane resin technology, this system delivers an exceptionally durable, chemical-resistant, and easy-to-maintain surface. By combining a resilient polyurethane matrix with graded aggregates, it forms a monolithic, flexible coating that withstands heavy traffic, impact, and harsh chemicals. It offers superior abrasion resistance, excellent adhesion to concrete, and a fast return-to-service time. The Polypro™ XT Topfloor system provides a long-lasting, low-maintenance flooring solution for warehouses, manufacturing facilities, food & beverage plants, and high-traffic commercial spaces.

The Challenge: Common Industrial Flooring Failures

Industrial and commercial floors face relentless daily assaults that conventional coatings often cannot withstand. Facility managers, contractors, and business owners grapple with:

Cracking and De-lamination: Rigid epoxy or cementitious floors crack under thermal movement or substrate shifts, leading to costly repairs and downtime.

Dusting and Degradation: Constant forklift and foot traffic wear down soft concrete, creating hazardous dust that contaminates products and machinery.

Attaque chimique : Spills from oils, solvents, acids, and cleaning agents quickly degrade standard paints and sealers, causing discoloration, softening, and failure.

Impact Damage: Dropped tools, parts, and rolling loads chip and crater brittle floor finishes.

Moisture Problems: Vapor transmission through concrete slabs can blister and ruin moisture-sensitive coatings.

Hygiène et nettoyabilité : Porous, cracked, or joint-ridden floors trap dirt and bacteria, making them unsuitable for food processing, pharmaceuticals, or healthcare.

The Polypro™ XT Topfloor Solution: Engineered for Performance

Our urethane flooring system is specifically formulated to address these critical pain points. Here’s how:

Unmatched Mechanical Durability

Exceptional Abrasion & Wear Resistance: Outperforms standard epoxy systems with a significantly lower Taber Abrasion loss value, ensuring the finish lasts for years under constant wheeled traffic.

High Impact & Point Load Resistance: The flexible urethane formulation absorbs energy, preventing cracks and chips from heavy impacts—ideal for warehouse aisles and assembly areas.

Seamless, Monolithic Surface: Eliminates joints and seams where dirt and moisture accumulate, creating a smooth, easy-to-clean surface that enhances sanitation.

Résistance supérieure aux produits chimiques et aux taches

Polypro™ XT Topfloor provides robust protection against a wide range of industrial chemicals, including:

Oils & Greases

Dilute Acids & Alkalis

Water & Saline Solutions

Alcohols

Many Solvents

This makes it perfect for automotive shops, chemical processing areas, and food & beverage facilities where spills are frequent.

Enhanced Safety & Physical Properties

Customizable Slip Resistance: Available in a range of textures, from smooth to heavily aggregated, to meet required slip ratings (e.g., R9-R11) for safety in wet or oily conditions.

Excellent Thermal Stability: Performs consistently across a wide temperature range, with superior resistance to thermal shock compared to epoxy.

UV Stability (for applicable topcoats): Resistant to yellowing and degradation from sunlight, suitable for areas with UV exposure.

Aesthetic Flexibility & Ease of Maintenance

Color & Finish Options: Choose from a standard palette of industrial colors or custom matches. Select from gloss, semi-gloss, or satin sheens.

Nettoyage facile : The non-porous, seamless surface can be quickly cleaned with standard industrial cleaners, reducing maintenance time and cost.

Long-Term Beauty: Retains its color and appearance far longer than conventional paints and coatings.

Efficient Installation & Sustainability

Rapid Cure & Return-to-Service: Faster cure times than many epoxy systems mean less facility downtime.

Moisture Tolerance: Certain formulations can be applied to damp concrete substrates without risk of blistering, reducing the need for extensive moisture testing.

Low VOC & Environmentally Conscious Options: Available in low-VOC formulations, contributing to better indoor air quality and compliance with environmental regulations.

Spécifications et données techniques

| Propriété | Méthode d'essai | Valeur typique / Résultat |

|---|---|---|

| System Type | - | Polyurethane (PUR) Resin-Based |

| Recommended Thickness | - | 1/16″ (Smooth) or 1/8″ (Textured) |

| Dureté | ASTM D2240 (Shore D) | 75-85 |

| Adhesion to Concrete | ASTM D4541 / Pull-Off | > 350 psi (Concrete Substrate Failure) |

| Résistance à l'abrasion | ASTM D4060 (Taber CS-17) | < 40 mg weight loss |

| Résistance à la flexion | ASTM C580 | > 2 000 psi |

| Résistance à la compression | ASTM C579 | > 8,000 psi |

| Résistance chimique | ASTM D1308 / Immersion | Excellent vs. oils, fats, acids, alkalis |

| Slip Resistance (Wet) | DIN 51130 | Class R9-R10 (varies with aggregate) |

| Operating Temperature | - | -40°F to +212°F (Continuous) |

| Cure à temps plein | - | 5-7 Days (for full chemical resistance) |

Applications idéales

Polypro™ XT Topfloor is the trusted choice across diverse sectors:

Warehousing & Logistics: For high-traffic aisles, racking areas, and loading docks needing extreme abrasion and impact resistance.

Transformation des aliments et des boissons : Provides a seamless, cleanable, USDA-compliant surface resistant to acids, fats, and hot water/sanitizer washdowns.

Pharmaceutical & Life Sciences: Creates a dust-free, monolithic floor suitable for cleanroom and controlled environments.

Automotive & Manufacturing: Withstands oils, coolants, and heavy rolling loads in plants, workshops, and showrooms.

Commercial & Institutional Garages: Offers a durable, attractive, and chemical-resistant finish for parking decks and service garages.

Aircraft Hangars & Maintenance Bays: Handizes heavy equipment, hydraulic fluids, and jet fuel while providing a safe, slip-resistant surface.

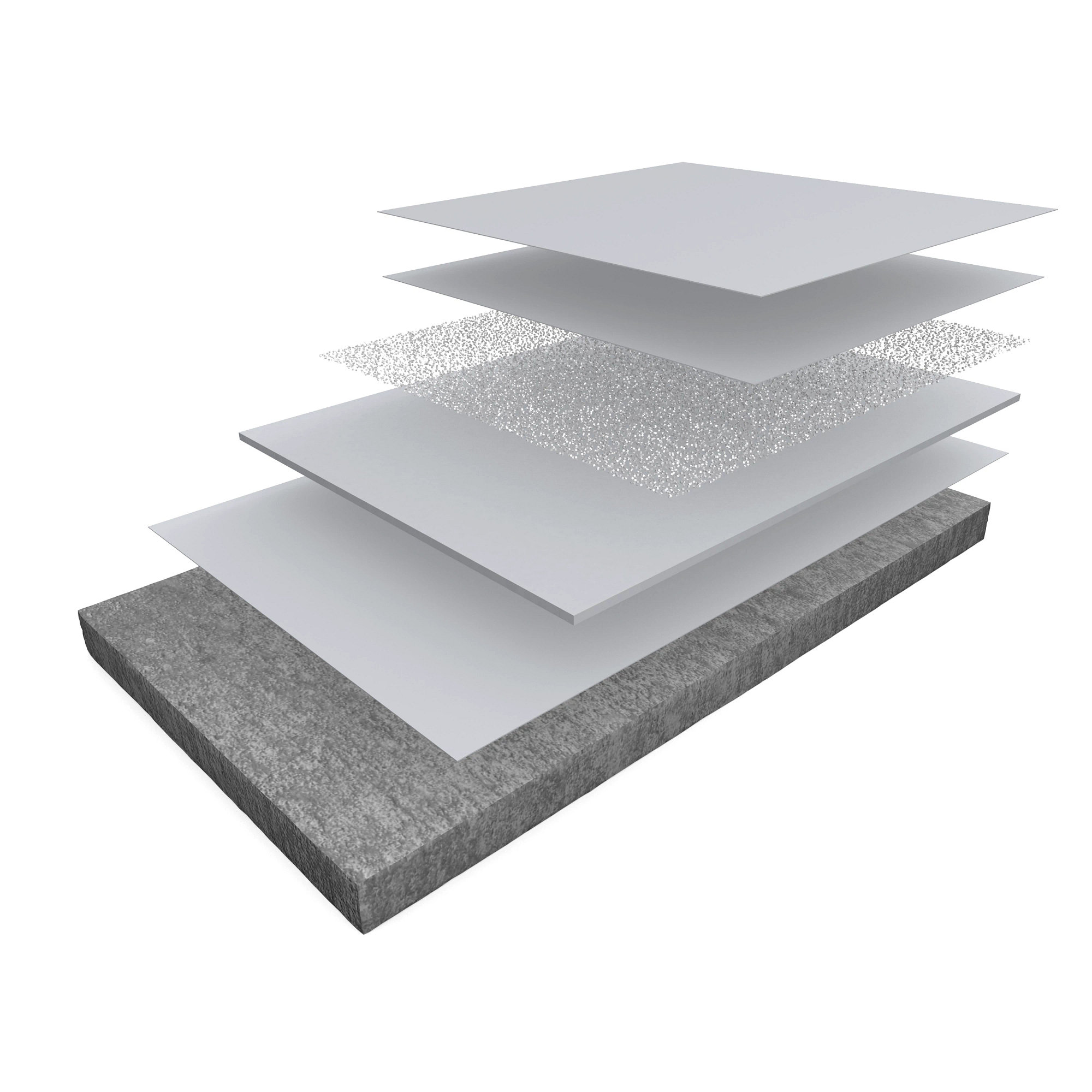

Professional Installation Process

Achieving the specified performance requires proper installation by certified professionals. The key steps include:

Surface Preparation & Inspection: Concrete substrates are abrasive blasted to achieve a CSP 4-6 profile, ensuring optimal adhesion. The slab is inspected for cracks, voids, and moisture.

Primer/Basecoat Application: A moisture-tolerant urethane primer is applied to seal the substrate and promote bond.

Mortar/Slurry Layer: A mixed layer of urethane resin and selected aggregates (e.g., quartz sand) is troweled to the desired thickness (1/16″ or 1/8″) to build strength and texture.

Grout/Topcoat Application: A final coat(s) of high-performance polyurethane topcoat is applied to provide the ultimate chemical resistance, color, and gloss finish. Optional broadcast aggregates can be embedded for slip resistance.

Curing & Protection: The floor is protected during the critical cure period before being released for light and then full traffic.

Our Support: We provide comprehensive technical support, including specification guidance, job-site audits, and installer training to ensure your project’s success from concept to completion.

Foire aux questions (FAQ)

What is the main difference between urethane and epoxy flooring?

While both are durable, urethane flooring like Polypro™ XT is more flexible, offers better abrasion and chemical resistance (especially to acids), and has superior UV and thermal shock stability. Epoxy can be more rigid and may chalk or yellow under UV exposure.

Can Polypro™ XT Topfloor be installed over an existing epoxy floor?

Yes, in many cases. The existing epoxy must be thoroughly profiled (e.g., by grinding) to provide a sound, clean surface for the urethane to adhere to. A site evaluation is recommended.

How long does installation take, and what is the downtime?

A typical installation for a medium-sized area can take 3-5 days, including prep. The system can often accept light traffic in 12-24 hours and full traffic in 3-5 days, minimizing operational disruption.

What maintenance does a polyurethane floor require?

Maintenance is simple. Regular sweeping and occasional damp mopping with a neutral pH cleaner are usually sufficient. Avoid harsh abrasive cleaners or steel wool.

Is this a DIY product, or do I need a professional installer?

For optimal, warrantied performance, Polypro™ XT Topfloor must be installed by certified and experienced flooring contractors. Proper surface prep and mixing are critical to the system’s success.

Why Choose Our Solution?

Des performances éprouvées : Specified by leading companies in manufacturing, logistics, and food processing.

Technical Leadership: Our formulations are developed based on deep industry knowledge and continuous R&D.

End-to-End Support: We partner with you and your installer, offering unmatched specification and technical service.

Quality Assurance: All produits are manufactured under strict quality controls, backed by comprehensive technical data sheets and guides.

KAIDA PAINT Flooring Brand

KAIDA PAINT is a leading innovator in high-performance industrial and commercial coatings. We specialize in developing advanced resinous flooring systems that solve real-world durability and maintenance challenges. Our Polypro™ XT Topfloor line exemplifies this commitment, offering a urethane-based solution that outperforms conventional options in toughness, chemical resistance, and longevity. We partner with professional contractors and facility managers worldwide, providing not just premium products, but complete technical support, specification guidance, and a guarantee of quality.

At KAIDA PAINT, we are more than just a coatings manufacturer; we are your strategic partner in industrial flooring solutions. With years of expertise in high-performance resin systems, including epoxy, polyurethane, and hybrid technologies, we understand the critical demands of your facility. Our Polypro™ XT Topfloor system embodies our commitment to innovation, durability, and value.

We collaborate directly with building owners, facility managers, specifiers, and qualified contractors to deliver floors that are built to last. From initial consultation and custom solution design to on-site technical support, we ensure your flooring investment performs as promised.

Ready to upgrade your space with a superior urethane floor?

Contact our expert team today for a free consultation, detailed product specifications, or to connect with a certified installer in your area. Let us help you build a stronger, safer, and more efficient facility.