Slippery floors are a common safety hazard in various production environments. Meat processing plant cutting areas are often covered in blood and grease. Oil manufacturing zones have oil spills. Beverage plant filling stations and seafood processing temporary holding areas are slick with water and mucus. Even cold storage floors can become dangerous due to ice or condensation. These conditions directly impact worker safety and operational efficiency. JINYU PAINT® Waterborne Polyurethane Mortar systems—the Grit Broadcast System and the UD System—offer targeted solutions for these challenges.

Grit Broadcast System: The Cost-Effective Choice for Low to Medium Temperature Areas

Our Waterborne Polyurethane Mortar Grit Broadcast System is perfect for low to medium-temperature environments requiring slip resistance. It performs reliably in temperatures from -18°C to 80°C. This makes it ideal for cold storage rooms, meat processing chillers, and bakery baking zones. It is also well-suited for oil packaging areas, precision machine assembly shops, and beverage filling lines.

This system effectively tackles slips caused by oil and water. In meat cutting areas, the broadcast grit creates a high-traction surface. This textured flooring prevents workers from slipping and stops carts and containers from sliding. In oil plants, the rough surface breaks up oil films. This ensures safe walking and prevents equipment from moving unexpectedly. For water in beverage plants or mucus in seafood areas, the anti-slip texture provides strong grip. This reduces accidents for both personnel and moving equipment.

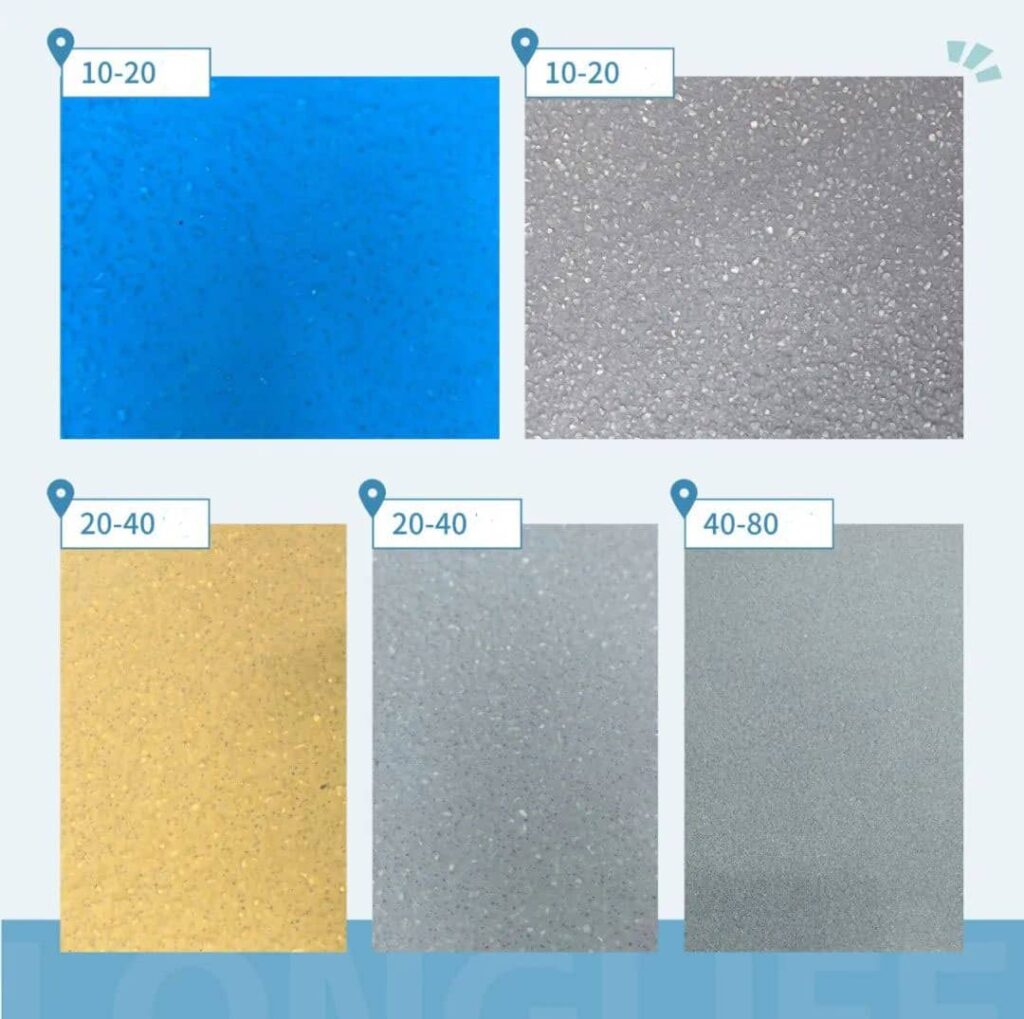

The system offers different grit sizes (fine and coarse) to meet specific needs. A standard thickness is usually sufficient. For areas needing essential slip resistance on a budget, this system is a practical and economical choice.

UD System: The Durable Solution for Demanding Environments

The Waterborne Polyurethane Mortar UD System is built for extreme conditions. It handles temperatures from -40°C to 150°C and offers superior slip and chemical resistance. It is the best choice for:

- High-temperature areas with oil, like scalding tunnels in meat plants or oil cooking zones.

- Areas needing frequent washdown, like slaughterhouse bleeding floors or fish processing lines.

- Chemically harsh environments, like pickle factory fermentation rooms (acid exposure) or heavy-duty mechanical workshops.

This system boasts an R13 slip rating—one of the highest ratings available. It provides strong grip even with mixed oil and water on the floor. This ensures staff safety and prevents heavy equipment or racks from sliding. It can withstand daily high-pressure washing in seafood plants without losing its anti-slip properties. With a thicker build and superior durability, a UD floor can last over 20 years, minimizing production downtime from repairs.

Choose the Right System for Your Food Factory Floor

For most food processing, beverage, oil, or precision machining plants, our two systems cover all needs.

- For moderate slip resistance: Choose the Grit Broadcast System for areas like cold storage, bakeries, or assembly areas. Select the correct grit size and thickness.

- For extreme conditions: Use the UD System for high-slip-risk areas. This includes cooking zones, slaughterhouses, and areas with acids. Its robust thickness provides a long-lasting, safe foundation.

Selecting the right floor prevents slips. It creates a stable base for workers, equipment, and material handling. This significantly improves overall production safety.

In summary, waterborne polyurethane mortar is the top choice for food plant flooring. It can be customized by area:

- Résistance au glissement for oily and wet zones.

- Static Control for sensitive electronic areas.

- Résistance chimique for areas with acids or alkalis.

Choose between the Grit Broadcast or UD System to balance performance and cost. Build a safe, durable, and compliant foundation for your food processing facility.

Comparison of Slip Resistance Ratings for Various Flooring Materials

| Type de sol | Slip Resistance (R-Value) |

|---|---|

| Dry Wear-Resistant Flooring | R9 ~ R10 |

| Liquid Hardener | R9 |

| Epoxy Self-Leveling | R9 |

| Epoxy Grit Broadcast | R11 ~ R13 |

| Acid-Resistant Brick | R11 |

| Cement Terrazzo | R10 |

| Revêtements de sol en mortier de polyuréthane | R12 ~ R13 |