Deskripsi

Ikhtisar Produk

ResuShield™ Topfloor MER II is a high-performance, crack-bridging epoxy flooring system engineered for demanding mechanical equipment rooms and industrial environments. It combines a flexible, waterproofing membrane with a chemically resistant topcoat to create a seamless, monolithic surface. This system provides exceptional durability, slip resistance, and long-term protection against cracks, chemicals, and heavy wear. Designed to deliver reliable performance without the use of migrating plasticizers, ResuShield™ Topfloor MER II offers a robust solution for companies and contractors seeking a permanent flooring coating for critical industrial spaces.

The Problem with Standard Industrial Flooring

Facility managers and contractors know the challenges of maintaining concrete floors in harsh settings. Common failures include:

Crack Propagation: Substrate movement causes cracks to reflect through standard coatings, leading to leaks and system failure.

Serangan Kimia: Spills from oils, fluids, and cleaning solutions degrade ordinary paint and sealers.

Abrasion & Impact Damage: Constant traffic from heavy equipment and dropped tools causes premature wear, dusting, and pitting.

Hygiene & Cleanliness Issues: Porous surfaces trap dirt and moisture, making cleaning difficult and compromising sanitation in commercial kitchens, locker rooms, and warehouses.

Our Solution: ResuShield™ Topfloor MER II System Features

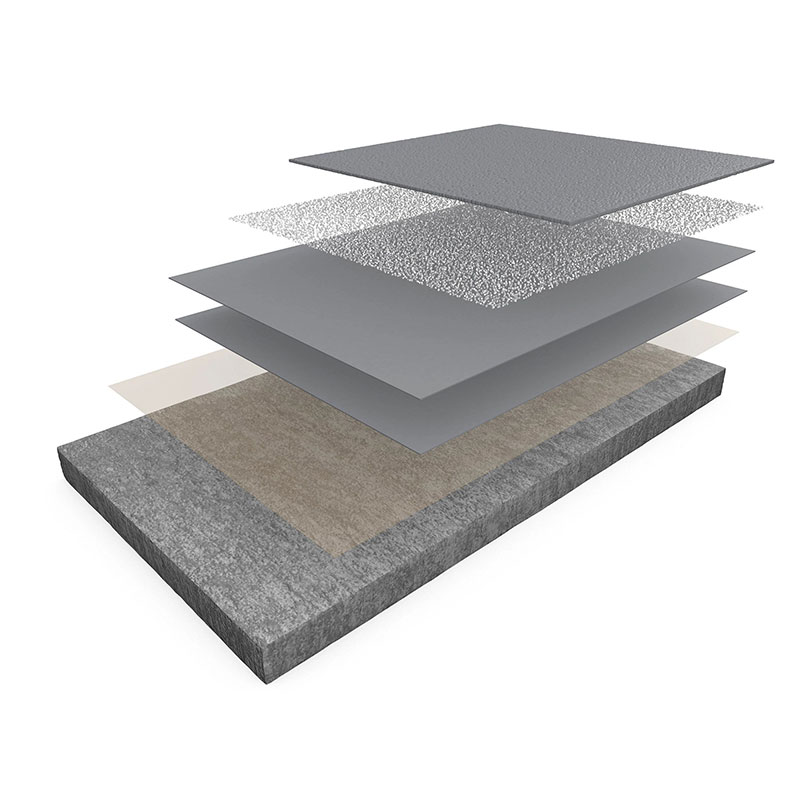

The ResuShield™ Topfloor MER II system is specifically formulated to address these industrial flooring challenges. Its multi-layer application ensures a complete shield for your substrate.

1. Unmatched Crack Bridging & Waterproofing

The core membrane layer is a flexible epoxy resin that bridges dynamic and hairline cracks in the concrete, preventing them from telegraphing to the surface. This creates a continuous, waterproof barrier that protects the subfloor from moisture infiltration, a critical feature for basement levels and areas exposed to water.

2. Superior Chemical & Stain Resistance

The topcoat provides a durable, non-porous finish that resists a wide range of industrial chemicals, including oils, greases, and mild acids. This makes cleaning spills quick and easy, protecting your concrete and maintaining a professional appearance. It’s an ideal solution for mechanical rooms, warehouses, and cleanrooms.

3. Enhanced Durability & Slip Resistance

An optional wearcourse layer, broadcast with hard aggregate like silica sand, can be added for extreme wear, impact, and abrasion resistance. This creates a textured surface that provides excellent slip resistance even when wet, enhancing safety in bathrooms, kitchens, and entryways.

4. Long-Term Flexibility & Performance

Unlike systems that rely on plasticizers, ResuShield™ achieves lasting flexibility intrinsically. This means the coating won’t become brittle or lose its crack-bridging ability over time, ensuring long-term performance and reducing the need for repair.

5. Customizable Aesthetic & Functional Finish

Available in standard and custom colors (gray, white, black, etc.) and gloss levels, the system can meet both functional and design requirements. The seamless, easy-to-clean surface is superior to tile or stone for industrial and commercial settings.

Technical Specifications & Data

| Parameter | Specification / Performance Data | Test Standard |

|---|---|---|

| System Thickness | 110 – 120 mils (2.8 – 3.0 mm) | ASTM D4138 |

| Kekuatan Tarik | Enhanced with optional fiberglass scrim | – |

| Resistensi Selip | Provides slip-resistant finish (can meet R9-R10) | DIN 51130 |

| Resistensi Kimia | Resistant to oils, greases, water, mild acids & alkalis | ASTM D1308 |

| Application Temp | Substrate: 60°F – 90°F (16°C – 32°C) | Manufacturer Spec |

| Waktu Penyembuhan Penuh | 24-48 hours to light traffic; 7 days for full cure | – |

| Konten VOC | < 100 g/L (Compliant with stringent regulations) | EPA Method 24 |

Ideal Application Areas

The ResuShield™ Topfloor MER II system is the best choice for a wide range of demanding environments:

Mechanical & Equipment Rooms: Protects floors from tool drops, fluid spills, and constant foot traffic.

Industrial Warehouses & Logistics Centers: Withstands heavy pallet jack and forklift wear, impact, and abrasion.

Commercial Kitchens & Food Processing Areas: Provides a seamless, chemical-resistant, and easy-to-clean surface that meets hygiene standards.

Locker Rooms & Showers: Offers waterproofing and slip-resistant safety in wet areas.

Parking Garages & Automotive Shops: Resists fluids, salts, and tire wear with a durable finish.

Professional Installation Process

A successful installation is key to performance. Our recommended process for contractors and professional installers includes:

Surface Preparation (Prep): Concrete must be abrasive blasted to a CSP 3-5 profile to ensure proper adhesion. All contaminants, laitance, and cracks must be addressed.

Priming: A primer (basecoat) is applied to seal the substrate and promote bond.

Membrane Application: The crack-bridging epoxy resin membrane is applied at 20 mils WFT.

Wearcourse (Optional): A second coat of resin is applied and immediately broadcast with sand or aggregate for texture and durability.

Topcoat Sealing: A final chemical-resistant topcoat or sealer is applied to lock in the aggregate and provide the final wear surface.

Curing: The system requires proper time to cure before being opened to traffic.

Catatan: We strongly advise partnering with a qualified installer or contractor experienced with epoxy flooring systems. KAIDA PAINT provides comprehensive technical support, from specification to application.

Pertanyaan yang Sering Diajukan (FAQ)

Q: What is the main difference between the MER II system and a standard epoxy coat?

A: The key difference is the integrated flexible membrane. While a standard epoxy coating may be hard, the MER II system is engineered to bridge moving cracks and provide true waterproofing, making it far more durable in environments with substrate movement.

Q: How long does the installation take, and what is the downtime?

A: The installation process typically takes 3-4 days for a standard area, including prep, application, and curing. The area should be closed to traffic for a minimum of 24-48 hours after the final topcoat, with full chemical cure achieved in about 7 days.

Q: Can this flooring be installed in a residential basement or garage?

A: While engineered for industrial and commercial use, its superior waterproofing and durability make it an excellent (though premium) solution for residential basements and garages where moisture or heavy use is a concern.

T: Perawatan apa yang diperlukan?

A: Maintenance is simple. Routine cleaning with a mild detergent and a bristle brush (for textured surfaces) is recommended. Avoid harsh solvents. Immediate cleanup of oil or chemical spills will prolong the finish. Periodic inspection and re-application of a sealer can extend service life.

KAIDA PAINT Brand Introduction

Your Trusted Partner for High-Performance Flooring Solutions

As a leading manufacturer and solution provider in the protective coatings industry, KAIDA PAINT is dedicated to developing advanced products that solve real-world durability challenges. We understand that your facility’s floor is a critical asset that impacts safety, productivity, and operational costs. Our ResuShield™ line, including the flagship Topfloor MER II system, embodies our commitment to innovation, quality, and long-term value. We don’t just sell paint; we deliver engineered solutions backed by expert technical service and support for contractors and companies worldwide. Our products are formulated for performance, ensuring your investment lasts.

Have a specific project or a challenging environment? Our technical experts are ready to assist. Contact KAIDA PAINT today for a personalized consultation and discover the difference a truly professional flooring system can make.