Deskripsi

Ikhtisar Produk

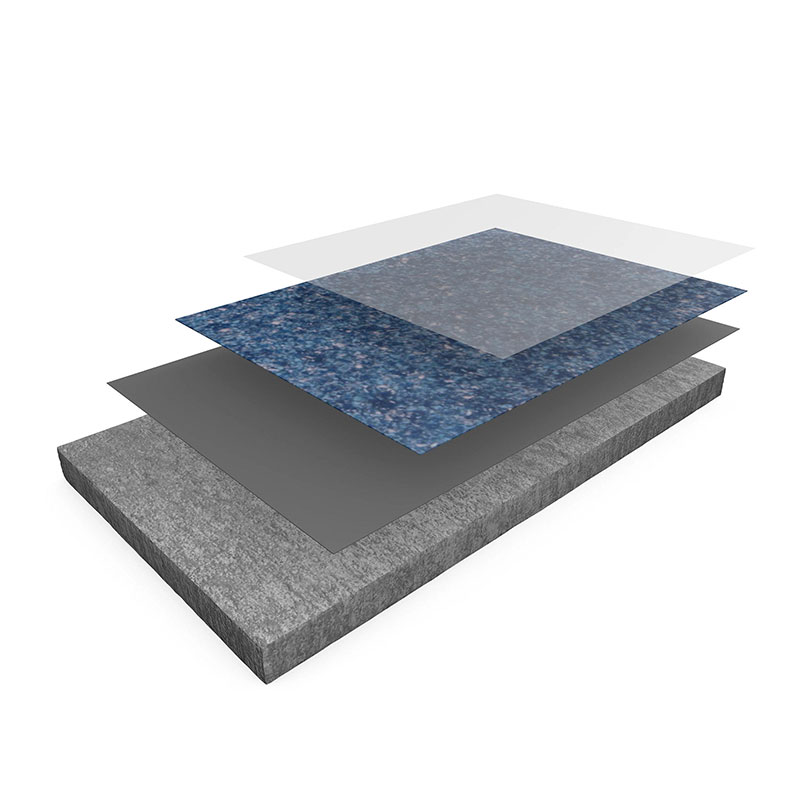

ResuShield™ DSS (Decorative Stone Slurry) is an innovative, three-layer epoxy flooring system designed to deliver a stunning, modern stone-like appearance with exceptional durability for demanding commercial and industrial spaces. By combining a pigmented epoxy primer, a decorative stone aggregate slurry, and a high-performance urethane topcoat, this system creates a seamless, high-performance floor with remarkable visual depth. It offers superior abrasion resistance, chemical resistance, and slip resistance while being easy to clean and maintain. The streamlined 3-layer application requires fewer steps than traditional decorative floors, enabling a faster return to service and lower labor costs. ResuShield™ DSS is the ideal flooring solution for facilities like warehouses, showrooms, healthcare labs, retail outlets, and hospitality venues that demand both aesthetics and long-term performance.

Common Flooring Problems & How ResuShield™ DSS Solves Them

Industrial and commercial floors face constant abuse that leads to costly repairs, safety hazards, and unsightly appearances. Here’s how ResuShield™ DSS addresses these core pain points for companies and contractors:

Problem: Rapid Wear & Tear from Heavy Traffic and Equipment. Constant foot and wheeled traffic can quickly wear down standard concrete or thin coatings, leading to dusting, cracks, and an unprofessional look.

Solusi: The ResuShield™ DSS system boasts exceptional mechanical properties. With a Taber Abrasion resistance of only 18 mg loss (ASTM D4060) and a compressive strength of 14,000 psi, it withstands the rigors of industrial and commercial environments for years.

Problem: Slippery, Unsafe Surfaces. Wet or greasy floors in kitchens, bathrooms, or food processing areas are a major liability, risking employee and customer safety.

Solusi: The topcoat is formulated for excellent traction. It achieves a wet static coefficient of friction (SCOF) of 0.94 (ANSI/NFSI B101.1), providing a slip-resistant surface even when wet, enhancing safety.

Problem: Stains & Chemical Damage. Spills of oils, solvents, or cleaning chemicals can permanently stain or degrade many flooring materials, requiring expensive repair or replacement.

Solusi: This epoxy-based system is highly resistant to a wide range of chemicals. Its non-porous, seamless surface prevents absorption, making it easy to clean and highly resistance to stains, perfect for labs, warehouses, and garages.

Problem: Long Installation Downtime. Traditional multi-layer decorative floors can take a week or more to install and cure, disrupting business operations.

Solusi: The simplified 3-layer application process reduces facility downtime significantly. The fast-cure components allow for quicker installation and a faster return to normal use, minimizing cost and inconvenience.

Problem: Dull, Uninspiring Aesthetics. Standard gray concrete or basic epoxy floors lack the visual appeal needed for customer-facing areas like lobbies, showrooms, or high-end retail spaces.

Solusi: ResuShield™ DSS offers a beautiful, customizable stone-like finish with unique visual depth. Available in a wide range of colors including popular shades of gray and white, it provides a high-gloss or satin aesthetic that elevates any space.

Core Features & Technical Advantages

Unmatched Durability & Performance

The ResuShield™ DSS system is engineered to last. Its robust construction ensures it can handle the toughest conditions.

Extreme Abrasion Resistance: Independent testing shows a Taber Abrasion loss of only 18mg (CS-17 wheel, 1000g, 1000 revs), far outperforming many standard epoxy floors.

Superior Strength: Features a tensile strength of 8,000 psi and compressive strength of 14,000 psi (ASTM D695).

Exceptional Adhesion: Bonds tenaciously to concrete, with adhesion test results often exceeding the strength of the concrete substrate itself (450+ psi, ASTM D7234).

Ketahanan terhadap benturan: The system absorbs shock, preventing chips and cracks from dropped tools or equipment.

Safety & Cleanliness

Create a safer, more hygienic environment with confidence.

High Slip Resistance: A wet SCOF of 0.94 meets or exceeds safety standards for wet areas, reducing slip-and-fall risks.

Seamless, Non-Porous Surface: With no grout lines or cracks to harbor bacteria, mold, or dirt, the floor is exceptionally hygienic and easy to clean with standard methods.

Flame Spread Resistance: Rated at 182 mm/min (ASTM D635), contributing to overall building safety.

Aesthetic Versatility & Customization

Move beyond basic floors to a custom-designed surface.

Natural Stone Appearance: Achieves the luxurious look of polished stone or marble without the high cost or maintenance.

Full Color Spectrum: Architects and designers can select from standard blends or create custom colors to match any brand or design scheme.

Finish Options: Choose between a sleek, high-gloss topcoat or a satin finish. For added texture and slip resistance, glass beads can be incorporated.

Optional Cove Base: Create a seamless, easy-to-clean transition from floor to wall with the integrated cove system.

Streamlined Application & Sustainability

Designed for efficiency from start to finish.

Faster Installation: The 3-layer system reduces labor time and complexity compared to 5-7 layer alternatives.

Low VOC Formulation: All system components—primer, slurry, and topcoat—are low-VOC, promoting better indoor air quality during and after installation.

Nilai Jangka Panjang: The combination of durability, low maintenance, and aesthetic longevity provides a superior return on investment compared to cheaper, less robust flooring options.

Technical Specifications & Data

The performance of ResuShield™ DSS is backed by rigorous testing against international standards.

| Properti | Test Method | Result / Specification |

|---|---|---|

| System Abrasion Resistance | ASTM D4060 (CS-17 Wheel) | 18 mg loss |

| Adhesion to Concrete | ASTM D7234 | >732 psi (Concrete Failure) |

| Wet Static Coefficient of Friction (SCOF) | ANSI/NFSI B101.1 | 0.94 |

| Kekuatan Tekan | ASTM D695 | 14,000 psi (96.53 MPa) |

| Kekuatan Tarik | ASTM D2370 | 8,000 psi (55.16 MPa) |

| Shore D Hardness | ASTM D2240 | 80-85 @ 0 sec / 75-80 @ 15 sec |

| Volatile Organic Compound (VOC) | ASTM D3960 | Primer: 0.19 lb/gal Slurry: 0.18 lb/gal Topcoat: 0.05 lb/gal |

| Water Absorption (24 hrs) | ASTM D570 | 0.2% weight increase |

| Mudah terbakar | ASTM D635 | 182 mm/min |

Ideal Applications

ResuShield™ DSS is the versatile choice for any space that demands beauty and brawn.

Commercial & Retail: Hotel lobbies, showrooms, restaurants, malls, and high-traffic corridors where first impressions count.

Industrial & Manufacturing: Warehouse aisles, factory floors, packaging areas, and clean rooms requiring durability and chemical resistance.

Institutional: School and university hallways, laboratories, hospital corridors, and locker rooms that need hygienic, easy-to-maintain surfaces.

Public & Recreational: Airport terminals, arena concourses, museums, and parking garages subject to constant public wear.

Makanan & Minuman: Commercial kitchens, food processing plants, and breweries where slip resistance and ease of cleaning are critical.

Professional Installation Process

For optimal performance, professional installation by certified contractors is recommended. The key steps include:

Surface Preparation & Assessment: The concrete substrate is inspected, moisture-tested (must be below 75% RH per ASTM F2170), and mechanically prepared via shot blasting to a CSP 5 profile (ICRI 310.2R) to ensure perfect adhesion.

Aplikasi Primer: A coat of pigmented Resuflor DSP epoxy primer is applied at 8-10 mils to seal the substrate and provide a uniform base color.

Decorative Slurry Installation: The ResuShield™ DSS slurry (resin mixed with stone aggregate powder) is applied at 60-80 mils, raked, and rolled to create the stone-like texture and color.

Topcoat Sealing: After the slurry cures and is lightly sanded, a final protective topcoat of clear, UV-stable polyurethane is applied at 3.2 mils for enhanced gloss, chemical resistance, and durability.

Curing & Handover: The floor is allowed to cure fully (typically 24-48 hrs for light traffic, 7 days for full properties) before being put into service.

Pertanyaan yang Sering Diajukan (FAQ)

Q: How does ResuShield™ DSS compare to traditional epoxy flake or quartz floors?

A: While flake and quartz systems are also durable, ResuShield™ DSS offers a more modern, stone-like aesthetic with greater visual depth. Its 3-layer system also typically requires less labor to install than multi-layer broadcast systems, potentially reducing overall project cost and time.

Q: What is the typical lifespan of a ResuShield™ DSS floor?

A: When installed correctly on a sound substrate and maintained properly, a ResuShield™ DSS floor can last 15+ years in heavy commercial or industrial settings. Its exceptional wear and chemical resistance contribute to its longevity.

Q: Can it be installed in a residential basement or garage?

A: Absolutely. While designed for commercial use, its benefits of durability, seamless design, and aesthetic appeal make it an excellent, long-lasting choice for high-end residential applications like garages, basements, and even bathrooms.

Q: How do I clean and maintain this type of floor?

A: Maintenance is simple. Regular sweeping or dust mopping, coupled with occasional damp mopping with a pH-neutral cleaner, is usually sufficient. Avoid harsh acids or abrasive cleaners to preserve the topcoat finish.

Q: What is the cost per square foot for a ResuShield™ DSS floor?

A: The total project cost depends on the condition of the existing substrate, the square footage, project location, and chosen color/finish. For an accurate quote tailored to your specific project, it’s best to consult with a certified installer or our technical team.

Trusted by Industry Leaders

ResuShield™ DSS is specified by architects and facility managers for demanding projects worldwide. It is manufactured to the highest standards, with performance data verified by independent laboratories against ASTM standards. Our network of professional applicators is trained to deliver flawless results, backed by comprehensive technical support.

Ready for a Floor that Combines Beauty with Unbeatable Performance?

Don’t settle for a floor that wears out, becomes unsafe, or fails to impress. The ResuShield™ DSS epoxy flooring system provides a proven solution that protects your investment and enhances your space for over a decade.

Contact us today for a free consultation, project quote, or to find a qualified installer near you. Let us show you how the right flooring system can transform your business.

KAIDA PAINT Brand Introduction

Your Trusted Partner in High-Performance Flooring Solutions

KAIDA PAINT is a leading manufacturer and solution provider specializing in advanced resinous flooring systems for industrial, commercial, and institutional applications. With a commitment to innovation, quality, and technical excellence, we develop products like the ResuShield™ DSS that are engineered to solve real-world flooring challenges. Our advantage lies in our dual role: as a manufacturer, we control the quality of every component, ensuring consistent, reliable performance. As a solution partner, we work directly with contractors, companies, and facility managers, providing end-to-end support from specification and technical guidance to on-site application assistance.

We understand that your floor is a critical asset. That’s why we don’t just sell paint or coatings; we deliver proven, long-term solutions that enhance safety, improve hygiene, and reduce total cost of ownership. Our team of experts is ready to help you select the right system, prepare a detailed specification, and connect you with our network of certified professional installers.

Stop searching for the “best” flooring option. You’ve found it. Contact KAIDA PAINT today to discuss your project requirements, request technical data sheets, or schedule a consultation. Let us help you build a foundation that lasts.